NASA orders second SpaceX ISS crew mission

This is the fourth and final guaranteed order NASA will make under Commercial Crew Transportation Capability (CCtCap) contracts.

Read MoreImagining the utility of IoT in our increasingly data-driven age

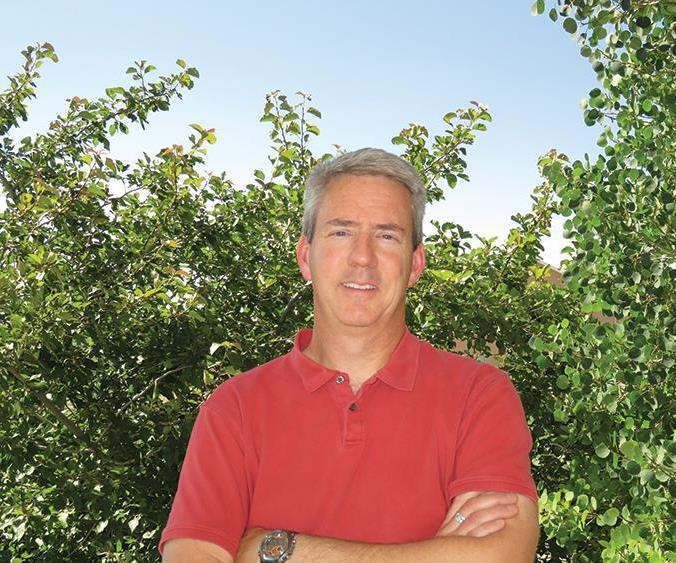

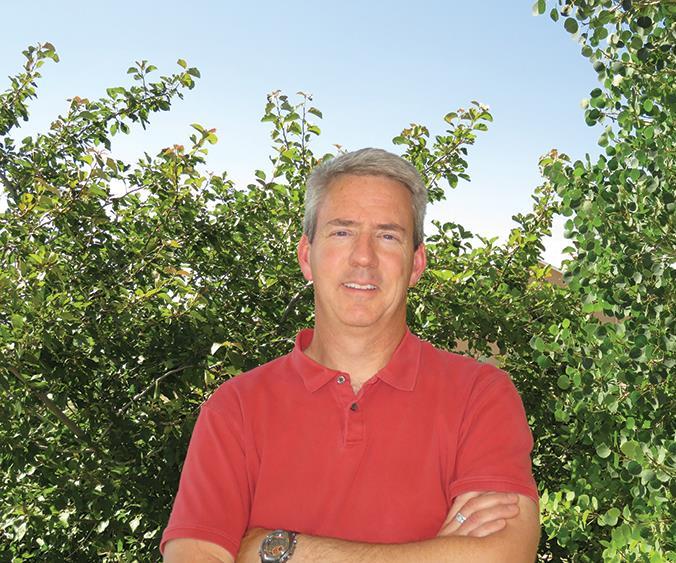

CompositesWorld's editor-in-chief Jeff Sloan imagines one potential outcome of the Internet of Things: inline composite part inspection.

Read MoreBringing lean manufacturing to cutting and kitting

AGFM/GFM is developing a cutting and kitting system designed to maximize operator efficiency at the cutting table, and to minimize ply layup sequencing errors during sorting.

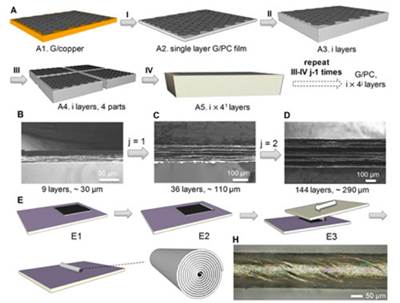

Read MoreMIT research proves viability of layering carbon nanotubes in composites

Massachusetts Institute of Technology (MIT) researchers have discovered significant advantages in composites fabrication by stacking layers of graphene or carbon nanotubes.

Read MoreCAMX 2016 preview: AGFM

American GFM Corp./GFM (AGFM, Chesapeake, VA, US; GFM, Styer, Austria) is introducing its Model US-120/CM-10 system, featuring automated and semi-automated ply cutting, sequential offloading, sorting and kitting to prepare for ply lay up.

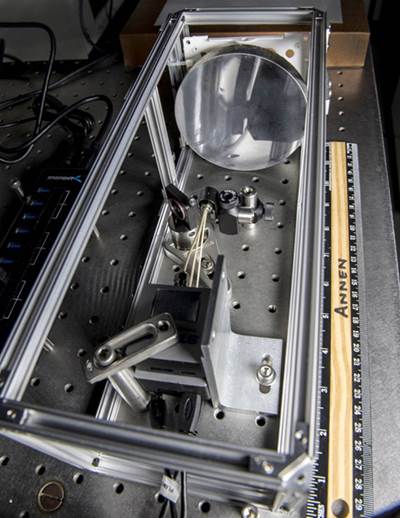

Read MoreNASA considers carbon nanotube mirrors for cubesat telescope

The carbon nanotube/epoxy combination is being evaluated for the fabrication of mirrors on cubesats for planetary space exploration and Earth observations.

Read MoreRMX Technologies to commercialize plasma surface treatment technology

After developing a plasma-based technology for carbon fiber oxidation, RMX Technologies is targeting plasma-based surface treatment technology.

Read MoreBuilding a market for recycled carbon fiber

Recycling uncured and cured carbon fiber was once a challenge, but that hurdle has been cleared. The difficulty we have now is in developing a market for what has become a mountainous amount of recycled material. CW's Carbon Fiber 2016 conference will address this issue.

Read MoreCooperating on new-generation ground transport

CompositesWorld's editor-in-chief Jeff Sloan shares his observations about the mixture of excitement and anxiety about the future of composite in the auto industry on display at the recent Thermoplastics Composites Conference for Automotive (TCCA), held in the Detroit suburb of Novi, MI, US.

Read MoreCovestro kicking the tires on polycarbonates for automotive

Although development work has only just begun, the company's Makrolon polycarbonate, in a carbon fiber-reinforced composite, is proving highly impact resistant and offers a Class A surface.

Read MoreMassive Stratolaunch nears completion

Paul Allen's Vulcan Aerospace is working with Scaled Composites to build the largest aircraft yet made, and it uses a lot of composites. The plane, it is hoped, will deliver satellites into low-Earth orbit — affordably and efficiently.

Read MoreTaking the hand out of hand layup

Hand layup has a long history in aerospace composites fabrication, but it's not well suited for automotive composites manufacturing, where volumes are much higher. But the discrete placement of fiber reinforcements still has value. Research is pointing toward automated hand layup that might help this process bridge the aerospace-to-automotive divide.

Watch