Composites recycling becomes a necessity

Boeing and Airbus each is generating as much as a 1 million lb of cured and uncured carbon fiber prepreg waste each year from 787 and A350 XWB production. If you include the entire supply chain for these planes, the total is closer to 4 million lb/year. And with the automotive industry poised to consume (and waste) more carbon fiber than ever, recycling of composite materials has become an absolute necessity. The technology is there, but the markets are not. Yet.

Read MoreDelta throws Bombardier's C Series a lifeline

After anemic sales threatened the future of the composites-intensive C Series, Delta's order of 75 CS100 aircraft, with options for 50 more, might have put the single-aisle aircraft on a path to sustainability.

Read MoreComing to carbon fiber: Low-cost mesophase pitch precursor

Advanced Carbon Products LLC has developed and patented a continuous manufacturing process for the production of mesophase pitch carbon fiber precursor that will cost as little as $1.50/lb.

Read MoreBigHead Bonding Fasteners wins funding for autocomposites work

UK-based bigHead Bonding Fasteners has won funding with Cranfield University to expand its capabilities for automotive composites applications.

Read MoreJEC World 2016: Automotive highlights

On the automotive side, Henkel (Düsseldorf, Germany) emphasized on its JEC stand a glass fiber-reinforced composite leaf spring, based on Henkel’s polyurethane matrix resin Loctite MAX 2, used in the chassis of the new Volvo (Gothenberg, Sweden) XC90, a premium crossover SUV; the platform of this vehicle is expected to be applied to other Volvo cars in the coming years.

Read MoreTeijin goes public with long-awaited Sereebo molding process

Teijin (Tokyo, Japan) revealed in Paris for the first time many details about its Sereebo high-volume composites manufacturing process.

Read MoreBMW cars again a composites showcase at JEC World 2016

BMW AG (Wolfsburg, Germany), already notable for its progressive use of composite materials in its i3 and i8 automobiles, provided the Parisian canvas for a palate of composites innovations.

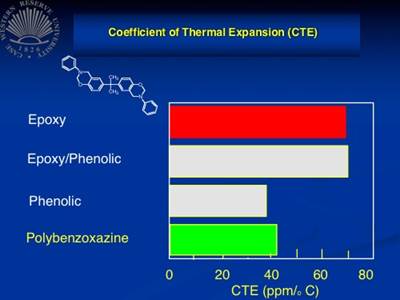

Read MorePolybenzoxazine on the horizon?

Benzoxazine veteran Dr. Hatsuro Ishida at Case Western Reserve University has developed what he calls the fourth generation of this versatile high-heat, high-strength matrix resin.

Read MoreCarbon fiber-based BMC wears well

Carbon fiber and ceramic are combined with a proprietary resin system to create a novel, extremely high-wear bulk molding compound (BMC) for centrifugal pump application.

Read MoreAshland unveils low-density, high-performance SMC

Ashland's new Arotran 771 sheet molding compound (SMC) offers a specific gravity of 1.2, with good mechanical and physical properties. The company is targeting 1.0 specific gravity, which would put SMC on par with aluminum in automotive applications.

Read MoreLocal Motors to use Siemens software for 3-D printed vehicles

The partnership combines Siemens’ PLM software technology with Local Motors’ leadership in co-created and 3-D-printed vehicles – direct digital manufacturing (DDM).

Read More