CAMX 2018: Second look, more new developments

Curved pultrusion for automotive, Smart Susceptors for primary structure repairs and Huntsman advances leaf springs for trucks, carbon wheels for automotive, “thin-ply” ailerons with Airbus and Nanocomp Technologies.

I’m actually going to cover these CAMX 2018 highlights out of order, starting with a new thermoplastic composite material on display.

SOURCE: CW

TEXIM thermoplastic prepreg

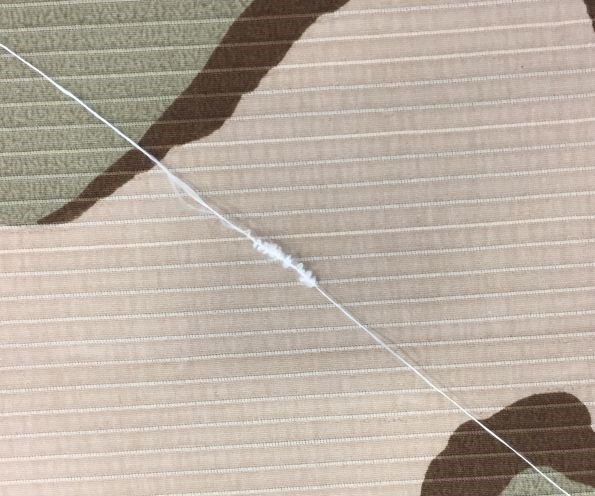

Inman Mills (Inman, SC, US) displayed TEXIM thermoplastic prepreg, which is made from its patented core yarn products, where a reinforcement fiber core (e.g., glass fiber) is sheathed within spun thermoplastic (TP) staple fibers. In the photo above at right, you can see where the TP sheath has been physically pushed back, highlighting the glass fiber core. The TP sheath may be made from polypropylene, polyethylene, polyester, nylon, polycarbonate, polyetherimide, polyphenylene sulfide or any other TP polymer that can be extruded into a fine staple fiber. The ratio of TP sheath to reinforcing fiber can be tailored to meet composite needs and the composite core yarns are easily processed via weaving, knitting or other textiles processes.

TEXIM could offer lower cost vs. other thermoplastic prepregs due to fewer processing steps — comprising only fiber production and textile processing — and reportedly enables good consolidation with improved drape and deep draw mold conformability. TEXIM glass and thermoplastic prepreg fabrics can be custom ordered for a specific thickness, thanks to multi-layer weaving capability, and are also available with third or fourth components, such as aramid filaments for impact resistance.

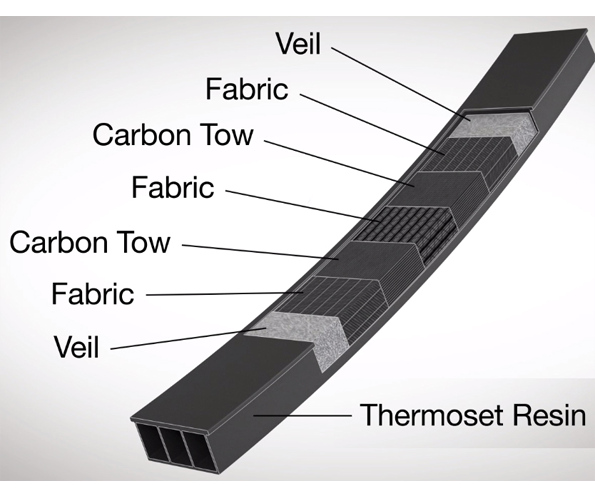

Curved pultrusion for automotive

In my previous blog on CAMX 2018, I showed L&L Products’ launch of Continuous Composite Structures (CCS) pultrusions for automotive components. This report is a second nod to growth in pultrusions for automotive, but via curved structures. Thomas Technik & Innovation displayed its Radius Pultrusion systems at CAMX 2018, highlighting the first operational unit in the US at Shape Corp (Grand Haven, MI). As described in the June 2017 CW article, “Curved pultrusion?”, Shape Corp is a global Tier 1 supplier of metal and plastic automotive components, but its Radius Pultrusion system was purchased “to enable manufacture of automotive bumper beams.” The company was a 2017 CAMX ACE award finalist in the Infinite Possibility for Market Growth category for its use of curved pultrusion to create highly engineered hollow and closed profiles. As shown above, the Radius Pultrusion technology also enables using multiple types of reinforcement in a single, tailored laminate.

SOURCE: Heatcon

Heatcon Smart Susceptors

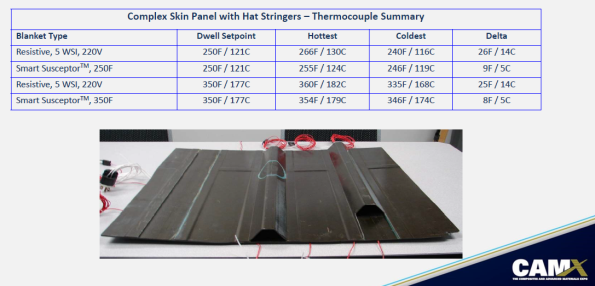

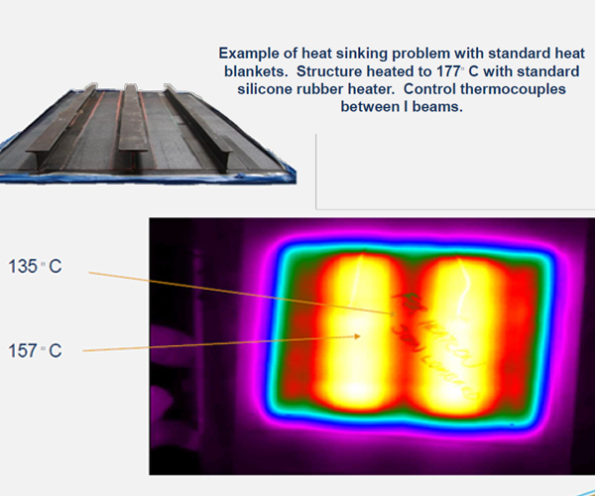

Heatcon supplies equipment and services for composite repair. The company displayed its Smart Susceptor heat blanket technology at CAMX 2018, offering a revolution in heat application for composite repair and curing through indirect inductive heating. Electrically resistive heat blankets have been the workhorse in composite repair for decades. While relatively robust and simple, they often cannot achieve sufficient temperature uniformity on thermally complex structures. They generate heat uniformly over the blanket area, but complex structures do not absorb heat uniformly due to differing material densities and heat sinks in underlying substructure. Smart Susceptor technology, conversely, transforms heat blankets to an active technology, reducing power (heat) to areas having achieved the desired temperature while continuing to apply heat to cooler areas. Thus, heat sinks are mitigated, ensuring increased temperature uniformity and duplicating original part manufacture conditions for repairs and secondary-bonding operations to provide the required level of structural integrity.

SOURCE: Heatcon

How does it work? Instead of the heat blanket’s primary wire being connected to a power source for resistive heating, in the Smart Susceptor system, it is connected to a high-frequency inductive power source. Energy is then electromagnetically transferred to a secondary heating wire. This secondary wire uses a metal alloy designed to have a Curie Temperature at the desired cure temperature. The Curie Temperature is the temperature at which the metal alloy loses its magnetic properties, and thus, its ability to generate heat via induction. Thus, at the desired cure or dwell temperature, the hot spots discontinue heating and start again if the temperature decreases, according to the curing program entered into the Smart Susceptor hot bonder unit. In a demonstration test using a complex composite skin panel reinforced with hat stringers, the temperature difference between hottest and coldest points during cure was only 5°C compared to 14°C using a resistive heat blanket.

SOURCE: CW

Huntsman advances leaf springs, wheels, thin-ply ailerons and nanotechnology

A wide variety of intriguing composite parts were on display at the Huntsman Advanced Materials booth. An automotive leaf spring produced by MBHA Composites — also known as ZIUR Composite Solutions (Villareal, Spain) — is used for heavy trucks and made using Huntsman epoxy resin in a high-pressure resin transfer molding (HP-RTM) process. CW has reported on glass fiber leaf springs made using epoxy prepreg and HP-RTM with polyurethane resin, but not yet on leaf springs made using epoxy and HP-RTM. “We worked with them for over one year, refining the epoxy formulation to get the best performance using HP-RTM,” says Huntsman business development manager Matt Pogue. He notes that in this product, Tg was considered but not critical. “But we have a newer, higher Tg system for composite applications located closer to exhaust systems,” he adds.

SOURCE: CW

Another automotive composite application on exhibit was an all-carbon fiber reinforced polymer (CFRP), one-piece wheel produced by ESE Carbon. “Carbon composite wheels are desired for higher performance and improved fuel efficiency, but they also are more expensive, which has been a key issue for widespread adoption” explains ESE Carbon CEO Carlos Hermida. “Our wheel is infused, which gives us more flexibility when selecting a resin to use, while also being more cost-effective for the automotive industry. We will be able to produce 25 wheels every 3 hours once we have finished scaling our facility in Jasper, Georgia.” ESE Carbon uses Huntsman Araldite epoxy resin. “We wanted a Tg above 200°C,” he explains, “as well as good flow for infusion and the ability to achieve a good cosmetic surface finish.”

“There is a lot of interest in carbon composite wheels, but it is a very challenging product as it has high temperature and structural requirements,” says Hermida. ESE Carbon is currently completing structural and performance testing including heated testing. “We will have wheels in road testing by early 2019,” he adds. The company is first targeting aftermarket and higher-end/low-volume performance car models. “We will keep moving toward higher production models as we scale in our manufacturing,” says Hermida. He explains that lighter wheels have a multiplier effect on weight reduction, “because of rotational inertia, every pound saved at the wheels is equivalent to roughly 4 pounds saved anywhere else in the car.” He notes that this appeal remains with electric vehicles due to their high battery weight and need to offset that elsewhere in the vehicle.

SOURCE: CW

Another eye-catching part was a CFRP aileron featuring logos from Airbus, North Thin Ply Technology (NTPT), Decision SA, RUAG, École Polytechnique Fédérale de Lausanne and University of Applied Sciences and Arts Northwestern Switzerland. “NTPT asked us for an epoxy resin that would work with their thin ply prepreg manufacturing system for a demonstrator production aileron for commercial aircraft,” relates Huntsman aerospace marketing manager Kyle Ingram. “We supplied the epoxy formulation and NTPT produced spread tow carbon fiber prepreg using its proprietary method. The finished part demonstrated that you can make a production-type aircraft structure with thin ply prepreg.” Ingram adds that the costs of conventional carbon fiber prepreg structures are still too high to be widely adopted in wings and fuselages for narrow body aircraft. “Thin ply now opens this door, but you must prove you can meet production cost and rate targets.”

CW also spoke with Huntsman VP of innovation David Hatrick regarding the company’s acquisition of Nanocomp Technologies. “The process of integrating Nanocomp into Huntsman is almost complete,” Hatrick explains. He notes that Huntsman has prioritized development of Nancomp Technologies’ MIRALON carbon nanotube (CNT) fiber in three main areas:

- Heating systems – conductive and radiative systems (e.g, automotive applications)

- Conductive adhesives

- Composites, including the NASA program to develop a second generation, more aligned “superfiber” with even higher properties than the current MIRALON CNT fiber.

There is also technology using MIRALON sheet as an interleaf in composite laminates, but Hatrick says this is not a high priority. “The R&D teams from Huntsman and Nanocomp have come together well,” he says, “and we have very clear milestones established.” Hatrick notes that the fact MIRALON fiber offers CNT technology in a fibrous form was attractive vs. working with particulates. “Our intent is to encapsulate it in resin or in laminated form.” He notes Huntsman is also working with Haydale and graphene materials. Again, the approach will be to encapsulate the graphene, selling it already mixed into resin. “The challenge is getting good dispersion that is stable for the life of the supply chain,” says Hatrick. “You must have good knowledge of the material and be able to scale in production, and also be able to offer good product support.”

Related Content

Pultrusion: The basics

A primer describing what pultrusion is, its advantages and disadvantages, and typical applications.

Read MoreExel Composites pultruded rods enhance Umbrosa parasol durability

The Belgium-based manufacturer chose pultruded fiberglass ribs for many of its umbrella and parasol designs to effectively endure exposure to high wind speeds, saltwater, rain and UV.

Read MoreCreative Composites Group introduces H-5 rated FRP bridge decking

High-strength pultruded SuperDeck Lite gives ambulances and maintenance vehicles access to trails, bridges, boardwalks and sidewalks

Read MorePultrusion, pull-winding showcase high-volume composites production

JEC World 2024: Exel Composites offers attendees a chance to engage with company experts and learn more about continuous composite manufacturing processes across various industries.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More