The Flexible Flyer: How composites made velomobile history

Separating frame and spring functions makes them easier to design but then those separate parts are heavier. Columnist Bob Stuart's updated velomobile suspension illustrates a way to combine those functions in a lighter, more responsive construction.

“I don’t like paying for a door hinge,” I said to the TV reporter as I opened up the flexible polycarbonate part of my velomobile door, “when I’ve already bought a windshield.” At the time, I was trying to win the Practical Vehicle Competition of the International Human Powered Vehicle Assn. (IHPVA, Cutten, CA, US). After three entries, my trike, the Car-Cycle X-4, won in 1996, 10 years after the debut of the trike’s running chassis at Expo '86.

As my combination windshield/hinge hinted, I’ve always loved to get two or more uses from each part. This made the functional integration that is possible with composites very attractive, especially for the critical structures underneath.

(Also, I was operating on a “student grade” budget, and big machine tools were out of consideration.) As a first prototype, the X-4 tested many ideas, some of which solved problems that turned out to be negligible, but the main experiment — integrating the frame with the suspension — turned out to be a big, easy win. The ride is so good, it feels like magic.

I grew up on race-car suspension ideals, but really appreciate the clever space-saving and often simplified systems in modern “econobox” cars. With less focus on maximum traction, they can have more forgiving handling as well as a better ride, and I think this helps to develop the reflexes most needed to miss a pothole or a puppy that suddenly appears in the road. The constraints of a flexible frame design barely affect ultimate performance, while saving much weight and cost.

The history of springs used as locating members has been mostly uninspiring, except for all the Hotchkiss rear axles produced with steel leaf springs. The Model T Ford used a pair of transverse leaves to the axles, providing a rather wobbly connection to a twisty frame, but the wheels were kept in alignment by subframes, so it worked. The Fiat Topolino pioneered the use of transverse leaf springs as locating members for independent suspension, and donated many parts to the revolutionary rear-engine Cooper Formula 3 race cars, but problems with unwanted flexing appeared.

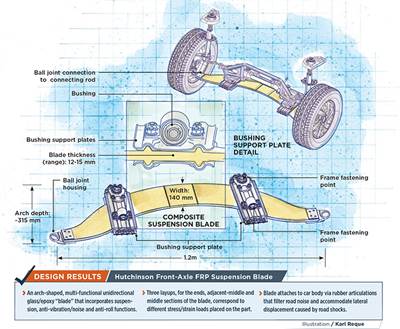

Automotive springs are unavoidably heavy: They must store enough energy to lift the frame from the bump stops, and their mountings generate high local stresses, which requires a heavy, reinforced section in metal. Composite leaf springs are far easier to produce in shapes that really fit the loads, and they can blend directly into the adjacent structure, with no fastener-related weight penalty. All we really have to remember is that a leaf spring should be arranged to respond to forces in one direction while resisting all others at nearly right angles. Short, wide springs are usually best, replacing the pivots on a control arm. I kept my spring sections short and distinct (as illustrated at left in the updated mockup of my Car-Cycle X-4 suspension). With the aid of finite element analysis, however, it should be possible to blend them much farther into the more rigid parts, getting double duty from more of the material. In practical terms, the stiffness of the composite used in the frame can be gradually reduced toward the most flexible spring section, with no abrupt distinctions between “rigid frame” and “spring.” By avoiding abrupt changes in stiffness, we employ more of the total material in the weight-intensive business of providing enough spring energy, and the load paths become very direct. This integrated structure is simpler and lighter, yet sacrifices nothing in terms of performance.

I missed a great two-for-one opportunity by not using two mounting lines on the main transverse leaf spring. This became a favorite trick at General Motors (Detroit, MI, US) because it combines the functions of spring and anti-roll bar into one elegant unit. As one wheel rises, the spring flexes down in the middle, lifting the opposite wheel to any degree you choose, according to relative lengths of spring. In the photo, notice that the left front wheel, although it is not impacted by a “bump,” lifts to a degree in concert with the right front wheel, to reduce roll (for more on suspension systems, read CW’s recent case study “Automotive front axle: A glass act,” located under "Editor's Picks" on the top right).

On my trike, I improved both roll and pitch stiffness by dividing the total travel between the wheels and using a separate suspension for the seat, which still felt stiff for pedal reactions. (The seat shape worked well in the original plan to have the rider shift his weight on corners. The lower arm of a simple parallelogram was split in two, to fit beside the backbone frame tube and blend into lower seat sections used for cornering.)

Even a plank-on-axle soapbox derby car achieves some suspension, and it is easy to find elegant ways to get more travel while retaining fine geometry, but we may miss the usual spring towers when it comes time to refine the ride with shock absorbers or load levelers. A composite transverse structure for springs and anti-roll functions can combine well with the steering and shock integration of a MacPherson strut. I used the bodywork to mount my rear shock, and showed that friction can still be used instead of hydraulics for shock absorbers. Parts rubbing together can dampen selected motions and dissipate heat just as well as hydraulic resistance. Two composite springs could work together to support a load, but be angled to rub where they touch, providing the necessary friction with minimal weight and expense.

Traditional stacked leaves can result in a “rising rate” spring with many benefits. It can provide a soft ride yet accommodate variable loads and offer better control on rough roads, but still allow the harmonic frequency to change with amplitude so it does not go wild on washboard even without shock absorbers. For vehicles with wider loading variations, it might be best to use composite leaf springs primarily as locating members, and then use hydrolastic elements to take care of load leveling and bounce control. They can pump themselves up or down, or integrate with digital controls. They could even power small generators, for maximum efficiency.

The flexible frame also needs to have an acoustic barrier or two planned in between the wheels and any large surfaces. We can do things like using a large chunk of engineered foam between a front crossmember and the frame, providing both isolation and hinges. With the steering box mounted on the crossmember, it becomes easy to keep the wheels aligned.

As the English scientist Thomas Young discovered at the dawn of modern engineering, everything is a spring. We might as well get used to it, and take advantage of opportunities instead of strictly segregating our almost-rigid and flexible components. Separating frame and spring functions make them easier to design but then those separate components wind up heavier. A more crashworthy design might have a rather floppy but tough composite monocoque that provides much of the spring action, with just a light, rigid subframe keeping the wheels aligned.

Related Content

Time Bicycles to modernize composite bicycle manufacturing

With the aid of KraussMaffei, Clemson University and SC Fraunhofer USA Alliance, Time anticipates a transition to HP-RTM for more efficient carbon fiber bike frame manufacture, plus a new facility in South Carolina.

Read MoreToray rCF from Boeing 787 is incorporated into ultra-light laptops

Torayca-based aerospace components have successfully been repurposed into the Lenovo ThinkPad X1 Carbon Gen 12, highlighting the ongoing application of recycled composites.

Read MorePlant tour: Arris Composites, Berkeley, Calif., U.S.

The creator of Additive Molding is leveraging automation and thermoplastics to provide high-volume, high-quality, sustainable composites manufacturing services.

Read MoreCarbon Mobile carbon fiber powers handheld gaming platform

HyRECM technology effectively stabilizes carbon fiber’s electrical and antenna properties, enabling development of next-gen electronics, such as the Snapdragon G3x Gen 2.

Read MoreRead Next

Automotive front axle: A glass act

The development of glass-fiber reinforced car axle is a sign of the new, expanded role composites will play in the design of future automobiles.

Read MoreModeling and characterization of crushable composite structures

How the predictive tool “CZone” is applied to simulate the axial crushing response of composites, providing valuable insights into their use for motorsport applications.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More