Airbus delivers second composites-intensive European Service Module for NASA’s Orion spacecraft

The ESM-2 module, comprising carbon fiber sheets and 19-meter CFRP solar array wings, will provide propulsion, power and thermal control, as well as oxygen and water for astronauts on the Artemis II mission.

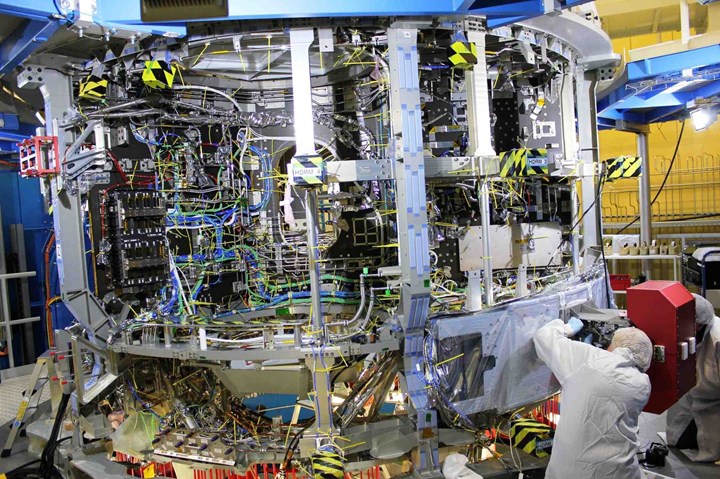

Integration of the ESM-2 for Orion. Photo Credit: Airbus

It was announced on Oct. 6 that the second composites-intensive European Service Module (ESM-2), built by Airbus (Toulouse, France) for NASA’s Orion spacecraft for the Artemis I and II moon missions, is ready for delivery from the Airbus site in Bremen, Germany. An Antonov cargo aircraft will fly the ESM-2 to NASA’s Kennedy Space Center in Fla., U.S. The European Space Agency (ESA) has selected Airbus as the prime contractor for the development and manufacture of six ESMs with the first ESM to fly soon on NASA’s Artemis I mission.

Airbus says the ESM is a key element of Orion, the next-generation spacecraft that will transport astronauts beyond low Earth orbit (LEO) for the first time since the end of the Apollo program in the 1970s. Comprised of more than 20,000 parts and components, ESM-2 is a cylinder around four meters high and wide. It has a distinctive four solar array wings (SAW, 19 meters across when unfurled) that generates enough energy to power two households. The service module’s 8.6 tons of fuel can power the main engine, eight auxiliary thrusters and 24 smaller thrusters used for attitude control.

While its primary structure is made from machined aluminum, the web assembly is composed of carbon fiber sheets and aluminum sandwich, to stiffen the central core and accommodate most of the ESM equipment (i.e., pressurant tanks, water tanks, etc.). The craft’s four SAW are each composed of three deployable carbon fiber-reinforced polymer (CFRP) rigid panels; at launch, the ESM weighs a total of just over 13 tons.

Overall, the module provides propulsion, power and thermal control and will supply astronauts with water and oxygen on future missions. Furthermore, the unpressurized service module can be used to carry additional payload. The ESM is installed underneath the crew module and together they form the Orion spacecraft, which will reportedly enables astronauts to be transported further into space than ever before.

“Delivery of the second European Service Module for NASA’s Orion spacecraft marks another huge step forward on the journey to return astronauts to the moon,” says Andreas Hammer, head of space exploration at Airbus. “Working hand in hand with our customers ESA and NASA, and our industrial partner, Lockheed Martin Space [see “Lockheed Martin opens new facility, expands Orion spacecraft production”], the program is moving apace and we are ready to meet the challenges of returning to the lunar surface in 2024.”

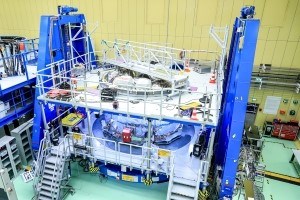

Photo Credit: Airbus

ESM-2 underwent a comprehensive validation process prior to being readied for shipment including gimbal testing of the module’s main engine (which swivels from side to side for maneuvering and directional control during spaceflight). This main engine is a refurbished engine from Space Shuttle Atlantis orbiter spacecraft.

After completing its trans-Atlantic voyage, Airbus says the ESM-2 will be mated with the Orion Crew Module and undergo further extensive testing before integration with the launcher, a process that will take around two years.

The launch of the first Orion spacecraft on NASA’s new Space Launch System rocket will be uncrewed and take the spacecraft more than 64,000 kilometers beyond the moon in order to demonstrate its capabilities. The first human spaceflight mission, Artemis II, will be powered by ESM-2. Eventually, the Orion spacecraft will transport four astronauts, providing life support for the crew during the flight and enabling a safe return to Earth’s atmosphere, at extremely high re-entry speeds.

In the longer term, ESM is planned to dock Orion spacecraft with the International Lunar Gateway, a moon orbiting platform that will enable a sustainable space exploration architecture extending humanity’s presence in space.

Related Content

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MorePlant tour: Middle River Aerostructure Systems, Baltimore, Md., U.S.

The historic Martin Aircraft factory is advancing digitized automation for more sustainable production of composite aerostructures.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More