Arevo introduces high-speed AM system, closes Series B financial round

The financing round and high-speed AM system for large continuous carbon fiber composite structures follow Arevo’s 3D-printed bicycle campaign.

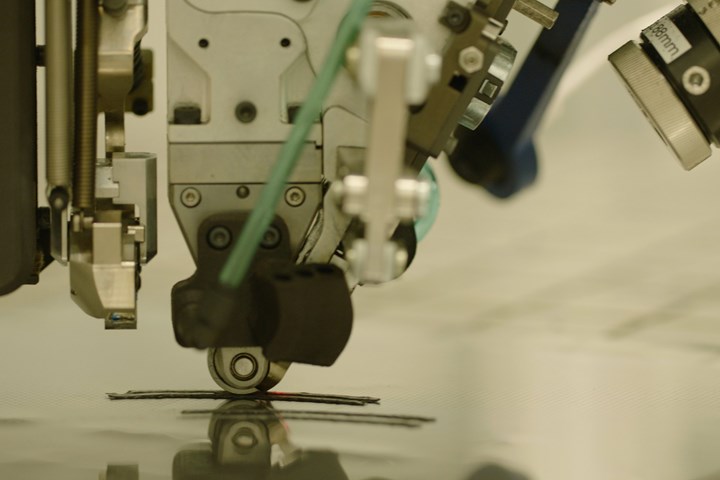

Aqua 2 printer head. Photo Credit: Arevo

Additive manufacturing specialist Arevo (Milpitas, Calif., U.S.) announced on August 11 the introduction of its newest system, the Aqua 2, what Arevo says is the world’s first high-speed additive manufacturing system for large continuous carbon fiber composite structures. In addition to higher quality, says Arevo, the Aqua 2 is able to print four times faster than its predecessor, enabling the rapid, on-demand production of large (up to one cubic meter) custom composite parts.

Additionally, the company closed its Series B financing round, led by Defy Partners and GGV Capital with participation from Khosla Ventures, Alabaster and others. This will bring the company’s total funding to $60 million. Defy appointed Brian Shin, a serial entrepreneur, investor and Defy Scout, to join Arevo's Board which includes Hemant Bheda (co-founder), Sonny Vu (CEO) and Bruce Armstrong (Khosla).

"Arevo's new platform enables fabrication of high-strength, low-weight carbon fiber parts, currently not possible with today's standard techniques," says Trae Vassallo, founding partner at Defy. "We are thrilled to be working with the team to help scale up this impactful technology."

These announcements come on the heels of Arevo's crowdfunding campaign to make its first direct-to-consumer products, the Superstrata bicycle and e-bicycle, said to be the world's first true unibody custom 3D-printed carbon fiber bikes.

Related Content

-

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

-

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

-

Bio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.