Aurora Flight Sciences to design high-speed, vertical lift X-plane

Program leverages more than 30 years of investment in novel VTOL and blended wing body platforms, targets first demonstrator flights within 42 months.

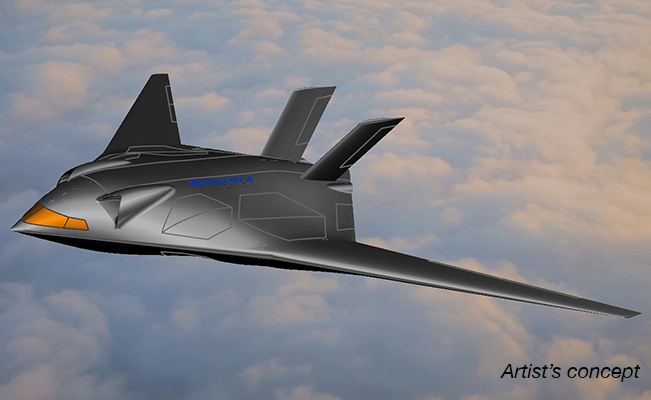

Artist’s concept of the X-plane demonstrator. Photo Credit: Aurora Flight Sciences

Aurora Flight Sciences (Bridgeport, W.Va.), a Boeing Company, has been selected for phase 1 of the Defense Advanced Research Projects Agency (DARPA) SPeed and Runway INdependent Technologies (SPRINT) X-Plane Demonstration Project. This project aims to design, build and fly an X-plane to demonstrate technologies and integrated concepts necessary for a transformational combination of aircraft speed and runway independence. This initial award funds work to reach a conceptual design review and includes an executable option to continue work through preliminary design review.

Under this award, Aurora is designing a high-lift, low-drag fan-in-wing (FIW) demonstrator aircraft that integrates a blended wing body platform, with embedded engines and moderate sweep, with a vertical flight design comprised of embedded lift fans linked to the engines via mechanical drives. The aircraft could deliver game-changing air mobility capability by combining cruise at more than 450 knots true airspeed (KTAS) with vertical takeoff and landing (VTOL) in a single platform.

The combined Aurora and Boeing team brings deep experience in agile vehicle prototyping, vertical lift and cruise transition technology, and blended wing body aeroperformance. The program will build on past flight programs like the Boeing X-48 blended wing body aircraft and the Aurora Excalibur UAS that combined jet-borne vertical lift with three electric, louvered lift fans that would retract into the wing in forward flight.

Design work will take place at Aurora and Boeing facilities across multiple states including Virginia, Massachusetts and Pennsylvania. The program is targeting first flight of the X-plane demonstrator within 42 months.

Related Content

-

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

-

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

-

Composites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.