Brighton Science unveils BConnect: The world's first surface intelligence platform

Next-generation solution combines diagnostic tools with data analytics to understand and prevent bonding and adhesion issues in composites and other industries.

Data and analytics enter—and transform—the invisible world of surface interfaces.

Brighton Science (Cincinnati, Ohio, U.S.) is a global pioneer in surface intelligence, combining decades of surface science expertise with precision handheld, automated and inline diagnostic tools and sophisticated software to bring visibility and insight to real-life adhesion, manufacturing, product development and supply chain challenges in the composites industry and other markets. Brighton Science serves customers such as NASA, Google, Honda and more across the electronics, medical device, automotive, aerospace and consumer goods industries, providing mission-critical decision information and a powerful competitive advantage to its partners.

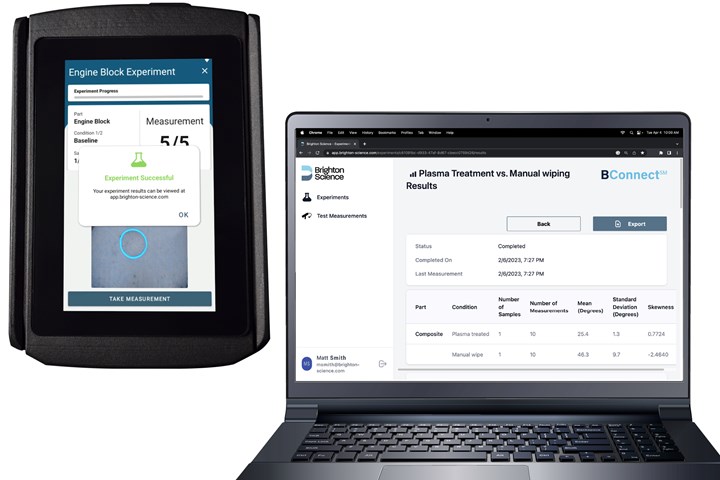

Brighton Science is now delivering its BConnect next-generation solution to help manufacturers better utilize data and analytics to prevent bonding and adhesion issues at all stages of the product life cycle. BConnect runs on Brighton’s proprietary SaaS platform and collects data from networked devices that assess surface readiness for bonding, coating or sealing by measuring the water contact angle. Because 90% of surface failures are due to a lack of surface readiness, getting this datapoint is critical throughout the development and production process.

Global enterprise tool for bonding, coatings, adhesives

Unlike tools that are centered on scientists and limited to the lab, BConnect gathers and distributes vital data to teams throughout the enterprise and around the world. This enables engineers, product designers, vendors, line operators, executive leadership and others to communicate with greater ease, speed and efficiency — bridging expertise gaps and language differences.

“Nearly every product that’s made today has some kind of surface bonding requirements, whether that’s paint, glue, coatings or adhesives,” explains Brighton CEO Andy Reeher. “For decades, companies have struggled to understand why certain materials fail, because what’s happening on these surfaces is invisible. Getting real-time surface readiness data and sharing it is a frontier where none have ventured before, and the implications are game-changing. If we can help our customers see what’s happening molecularly on those surface interfaces, they can get more predictability and assurance with their bonds, which will unleash innovation with new materials and make their existing products more durable and sustainable.”

Brighton Chief Science Officer Giles Dillingham, Ph.D., concurs, “The rate of innovation in manufacturing is exponential right now, with revolutionary new materials. Yet unseen environmental conditions and simple human choices continue to compromise surface integrity. Our BConnect system can now accomplish what traditional QA cannot—bringing more visibility and certainty to the manufacturing process.”

BConnect service

BConnect is a subscription-based offering that includes highly sensitive mobile and inline sensors that collect surface readiness data and wirelessly upload it to the BConnect cloud-based SaaS platform. Completely customized for each company and its users, these surface intelligence networks give teams a common language and data set to innovate, troubleshoot and optimize processes while reducing costly waste and recalls. All data collected via BConnect is private and proprietary to each company.

Companies that subscribe to BConnect can also opt in to the SIQ Community, an emerging industry collective committed to advancing knowledge and driving innovation in the surface science space—collaborating on topics like increasing sustainability, speed and safety in global manufacturing.

Related Content

Sulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MorePlant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More