CAELESTIS R&D project explores predictive design, manufacturing for aerospace

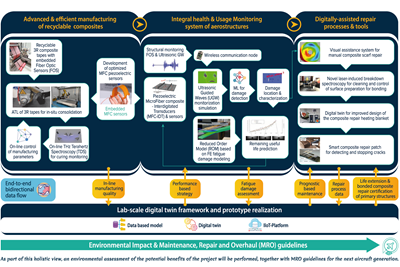

Over 42 months, 11 partners will work together to develop an end-to-end digital thread to effectively enable dataflow across the entire aircraft value chain, accelerating the optimization of disruptive aircraft and engine configurations.

The CAELESTIS team on a tour of AIMEN in Spain during the project kick-off meeting on May 9th, 2022. Photo Credit: © RTDS

CAELESTIS, a project funded by the European Climate Infrastructure and Environment Executive Agency (CINEA) through the EU’s Horizon Europe program, seeks to conduct groundbreaking research into digital twins for the development and exploitation of the CAELESTIS Interoperable Simulation Ecosystem (ISE). This system will effectively enable dataflow across the entire aircraft value chain, further linking together engineering, design and manufacturing, thus aiding worldwide manufacturers in their journey to decrease CO2 emissions stemming from aviation, reduce the costs and risks in developing new aircraft designs and shorten lead times for innovating more efficient aircraft.

In particular, the end-to-end ISE will perform multidirectional data flow across the aircraft value chain. This will link product design with distributed CAD-CAE tools to accelerate the optimization of disruptive aircraft and engine configurations and ensure their feasibility. ISE will be developed to integrate and autonomously execute simulation workflows supporting design and optimization across aviation’s entire supply chain. The ecosystem will require high-performance computing (HPC) infrastructures capable of executing predictions deliver outputs at realistic time scales. Machine learning tools will improve the detection of manufacturing flaws, and quantify such uncertainties and their influence on the structural integrity of aircraft parts.

The kick-off meeting for the CAELESTIS project took place in Spain in May 2022. Representatives from 11 partners from seven EU member states (Austria, Cyprus, Finland, France, the Netherlands, Spain and Sweden) are participating in the project across a variety of work packages formulating the research project’s backbone, with AIMEN Technology Centre (Galicia, Spain) acting as the project’s lead coordinator. By exploring the potential for digital twins to speed up innovation in aeronautics, CAELESTIS comprises a key contribution towards Europe’s 2050 climate goals.

CAELESTIS is a 42-month project with a budget of almost €6 million. Key objectives include:

- Create a digital thread across the value chain linking the design, simulation, production engineering and manufacturing of next-generation airframe and engine structures;

- Develop model-based product and manufacturing digital twins, supporting virtual prototyping of next-generation aerostructures by linking and managing design and manufacturing uncertainties;

- Develop advanced HPC-data analytics that supports the design and manufacturing engineering;

- Mature smart manufacturing strategies to identify and reduce the impact of defects across the manufacturing chain in real time;

- Foster the uptake of the CAELESTIS virtual prototyping ecosystem across the EU aeronautics industry to boost innovation for the future aircraft with a Multi-Actor Approach.

“The CAELESTIS project is a research project funded in the Horizon Europe program, focused on the aerospace industry and tries to digitalize the whole process of designing and manufacturing of aerospace parts,” an AIMEN project coordinator explains. “It could impact the aerospace industry by introducing the digitalized framework that will connect design with manufacturing and integrate simulation and machine learning algorithms in a high-performance computing framework in order to optimize the solutions and requirements of the aerospace parts. The CAELESTIS project tries to reduce the weight of the aerospace parts by implementing this digital framework, and in that way reduce the consumption of fuel and the gas emissions in the aerospace industry.”

Visit this link for more information and updates about the project.

Related Content

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreWelding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

Read MoreNext-generation airship design enabled by modern composites

LTA Research’s proof-of-concept Pathfinder 1 modernizes a fully rigid airship design with a largely carbon fiber composite frame. R&D has already begun on higher volume, more automated manufacturing for the future.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreRead Next

AMULET project funds 24 projects in composites, CMCs, metals

Trans-European project finalists for first open call identify material and process innovations in building, aerospace and aeronautics, energy and automotive sectors.

Read MoreEUVAM project investigates energy-efficient UV process for composites curing

University of Stuttgart researchers intend to develop flexible, highly productive and digitally controllable manufacturing approach for small urban vehicle production.

Read MoreEU-funded GENEX project to develop digital twin framework for aircraft lifecycle tracking

Novel digital framework to enable holistic and comprehensive data capture through the entire aircraft lifecycle, supporting composite component/structure manufacture optimization and maintenance.

Read More