Fiber Dynamics invests in GX 1100 DCIM from KraussMaffei

Direct compounding injection molding (DCIM) enables the composites company to develop, test and protect its own recipe formulations, while increasing cycle times by eight times and reducing energy consumption.

Composites solutions specialist Fiber Dynamics Inc. (Wichita, Kan., U.S.) has invested in KraussMaffei’s (Parsdorf, Germany) GX 1100-4300 direct compounding injection molding (DCIM) machine as the company moves to thermoplastic injection molding and compounding. Fiber Dynamics chose this equipment for its recipe sovereignty, enabling greater flexibility as well as faster cycle times and improved cost-effectiveness.

Fiber Dynamics has been developing and manufacturing highly complex articles from composite materials for 40 years. Its customers come from a wide range of industries, including aerospace, defense and automotive. The company is open to new economical manufacturing processes; when designing the right solution, Fiber Dynamics focuses not only on component-specific properties such as weight reduction or higher strength through integrated structures, but also the elimination of secondary assembly processes, a higher degree of automation and shorter cycle times.

Prior to the purchase of the DCIM machine, Fiber Dynamics was looking to expand production. It was also facing challenges with the production of propeller blades for the advanced air mobility (AAM) market. The company’s existing lost core tooling system (LCTS) took too long, had formulation limitations and was too costly using traditional methods. Injection molding was an obvious solution, but producing its proprietary and highly customized formulations posed an additional challenge.

Fiber Dynamics also sees future potential for DCIM technology in the automotive and sporting goods industries.

“KraussMaffei was able to quickly understand our problem and offer us a solution with its DCIM technology,” says Darrin Teeter, CEO of Fiber Dynamics. “In addition, KraussMaffei was able to demonstrate and implement the solution quickly.”

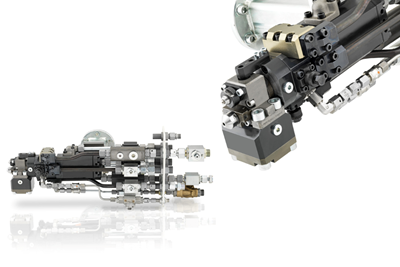

The DCIM process combines injection molding and compounding in a single process. A single-screw extruder handles the material preparation, making the process particularly cost-effective for smaller components with a shot weight of 50-2,000 grams. Material savings of up to 50% per kilogram can be achieved.

Moreover, the entire process takes place in one go, as the compounded melt enters the plasticizing process of the injection molding machine without any intermediate stops or cooling. This reduces polymer degradation, saves energy costs and reduces the CO2 footprint.

Fiber Dynamics highlights the DCIM’s cycle times — reported to be eight times faster compared to the LCTS — but also the technology’s recipe control. “The ability to test a variety of different formulations and quickly develop new ones is crucial to the success of our program,” says Teeter. “Externally compounded formulations are generally not practical for our work and jeopardize the proprietary nature of our solutions. The ability to also produce technical thermoplastic molded parts and thermoplastic composites also opens up a whole new dimension of versatility and added value for the company.”

An important partner in this project is the National Institute for Aviation Research (NIAR, Wichita, Kans., U.S.) Advanced Technologies Lab for Aerospace Systems (ATLAS). With 1,400 employees and an annual research budget of more than $240 million, NIAR is a leading research institute in the field of U.S. aviation. Since mid-2023, ATLAS has been operating a GX 450-1400 from KraussMaffei in its 150,000 square meter research pilot plant, which is also designed for the FiberForm and ColorForm processes.

“When we discovered the potential to produce our LCTS materials by thermoplastic injection molding, we were able to use the laboratory machine at ATLAS to carry out important validation processes,” adds Teeter. “The results were excellent, so we quickly decided to purchase the DCIM system.”

The GX 1100-4300 DCIM system, with a clamping force of 11,000 kilonewtons, is scheduled to start production in Wichita in May 2024. Initially, it will produce tooling mandrels for composites articles in aircraft, such as propeller blades, wings and landing gears. Fiber Dynamics also sees future potential for DCIM technology in the automotive and sporting goods industries.

Related Content

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreJeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MorePultrusion: The basics

A primer describing what pultrusion is, its advantages and disadvantages, and typical applications.

Read MoreRead Next

HyWaSand demonstrates large-series production potential for automotive TP sandwich components

Storage compartment flap for truck interior produced via fully automated continuous fiber thermoplastic sandwich molding technology shows suitability for series manufacture.

Read MoreKraussMaffei optimizes SCS process with quick nozzle change module

Efficiency, resource optimization and environmental responsibility are key focuses behind the seamless switch between flat and round jet nozzles, used for spraying polyurethane onto composite components.

Read MoreENRX, Roctool collaborate to advance mold electrification

Plastics and composites manufacturers will benefit from Roctool’s heat and cooling induction for molding processes, with increased technical service support and capability demonstrations on a global scale.

Read More