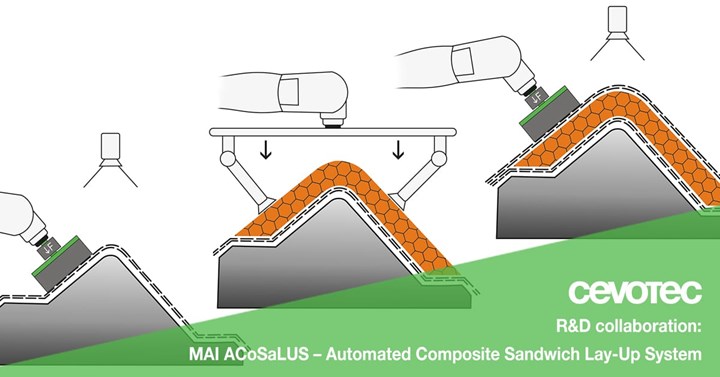

Cevotec's MAI ACoSaLUS project aims for full automation of composite sandwich structure production

Cevotec works with GKN, TU Munich, SGL Carbon and Augsburg University with an aim to fully automate layup of sandwich parts using FPP, achieve 7-10 times improvement in layup speed.

Photo Credit: Cevotec.

Together with GKN Aerospace Deutschland GmbH (München, Germany), TUM – Chair of Carbon Composites (Garching, Germany), SGL Carbon (Wiesbaden, Germany) Augsburg University of Applied Sciences, and under the co-founding authority of Bavarian Ministry of Economic Affairs, Regional Development and Energy, Cevotec (Munich, Germany) started a pioneering R&D project, MAI ACoSaLUS (Automated Composite Sandwich Lay-Up System). Through this project, Cevotec says it will advance its fiber patch placement (FPP) technology with inline inspection capabilities for further industrialization.

Emissions reduction is a major driver for new process developments and part certifications. The continued effort to reduce emissions in the aerospace industry has led to the widespread adaptation of composite materials and sandwich structures. The latter use foam and/or honeycomb core materials to increase stiffness at very low weight and offer additional benefits such as thermal and noise insulation. However, say Cevotec, they still greatly depend on manual labor and multiple, subsequent inspection steps to assure compliance with tight quality specifications, which is where the company’s FPP process comes in.

“The FPP technology is unique in its capability to layup fibers on surfaces with compound bends,” explains Cevotec CEO Thorsten Groene. “We want to extend this to the automated layup of complete sandwich components, including core materials.” Key targets of the ACoSaLUS project are to reduce the amount of manual labor needed by up to 100% and to increase the net layup speed by a factor of 7 to 10, reaching 15 square meters/hour.

Achieving these project goals will make the production of composite sandwich components more affordable, efficient and controlled. Cevotec’s scope of work within the ACoSaLUS project encompasses both software and hardware developments, including further advancement of the FPP process. “We will implement an active force-feedback function on the robot integrated in our system to meet optimal compaction forces during the layup process while also enhancing our proprietary gripper technology,” says Richard Carle, ACoSaLUS project lead at Cevotec.

Regarding software, Cevotec is working with the Augsburg University of Applied Sciences on an optimization of the FPP layup planning and simulation algorithms to reduce the overall cycle time per component and to further increase the quality of mechanical strength predictions. To ensure the produced components match the strict manufacturing specifications needed by aerospace customers and Tier 1 suppliers, Cevotec will develop a vision system to inspect the first and second skin laminates during the placement process. This will be done in close cooperation with GKN Aerospace GmbH and VisCheck GmbH (Bayern, Germany). New prepreg formulations developed by SGL Carbon will also be tested during the project to optimize their use on Cevotec systems. In addition, Vabatec GmbH (Munich, Germany) will further develop its newly developed gripper-based application technology for vacuum aids.

At the project’s completion in 2023, Cevotec aims to achieve 7-10 times improvement in the net layup speed of relevant components and to develop a fully automated layup process for sandwich parts using FPP technology, including advanced inline inspection routines and self-adaptive process control, advanced placement routines and automated core handling, with the objective to transfer the developments into aerospace series production.

Related Content

-

ST Engineering MRAS presents initiatives to drive autoclave efficiency, automation

During a JEC World 2024 panel discussion, the company revealed ways in which it is maximizing throughput and efficiency of its autoclaves and enhancing composites production processes.

-

Toray announces growth, investment in carbon fiber composite materials

As part of its 2023-2025 management strategy, Toray projects 42% growth for pressure vessels, 30% growth in carbon fiber composite materials revenue and a doubling of capital investment.

-

SAM XL demonstrates closed-loop digital methodologies via full-size aerocomposite parts development

PeneloPe Project’s modular, zero-defect manufacturing deliverables are being highlighted in an upcoming video that demonstrates the resulting aerospace pilot line’s feasibility.