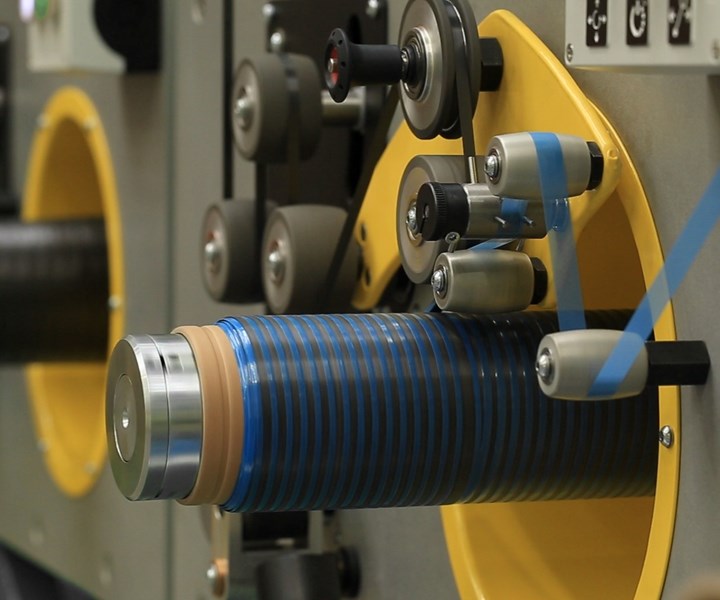

Cygnet Texkimp signs slitter-spooler contract with Chinese composites company

The industrial-scale machine will be used to slit sheets of carbon fiber prepreg into tapes for aerospace components.

Share

Source | Cygnet Texkimp

Cygnet Texkimp (Northwich, U.K.) has signed a deal to supply an industrial-scale slitter-spooler to a manufacturer of aerospace-grade composites based in China.

The company says that the machine will be used to slit sheets of carbon fiber prepreg into tapes before winding it onto spools. The tapes will then be fed into an automated tape laying (ATL) machine used to make components for the aerospace industry. For this application, the slitter-spooler will be fitted with eight tape winding heads, but Cygnet Texkimp claims the technology can accommodate up to 48 heads. The machine also reportedly slits with an accuracy of width greater than +/-0.125 millimeters and at a speed of up to 50 m/min.

“We launched our slitter-spooler machine 12 months ago to make carbon fiber prepreg tape more accessible to the market,” explains Neil Anderton, sales director at Cygnet Texkimp. “We had spotted a gap in the market that we could fill by designing a slitting and spooling machine that fits alongside our traditional portfolio of fiber unwinding creels, prepreg, filament winding, coating and laminating technologies.”

Anderton adds, “We’re enabling our customers to integrate the slitting process into their production lines in a way that gives them total control over production quality and speed and makes the whole process more simple, efficient and profitable.”

Related Content

-

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

-

Bio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

.jpg;width=70;height=70;mode=crop)