Decathlon selects GreenPoxy bio-resin for latest sustainable wakeboards

The sports equipment giant combines GreenPoxy 33 with FSC-accredited wood cores and monitors all ecological impacts of the manufacturing process, keeping the environment at the heart of its newest designs.

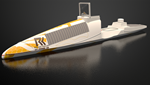

Photo Credit, all images: Sicomin Epoxy Systems, Decathlon

Sicomin Epoxy Systems (Châteauneuf les Martigues, France) announces its new collaboration with sports equipment giant Decathlon (Lille, France). Sicomin will supply its GreenPoxy 33 resin to produce Decathlon’s new JIB and Block wakeboards that will be manufactured at Meditec, the specialist composite board manufacturer based in Tunisia, North Africa.

With a desire to produce products that are as sustainable as possible, GreenPoxy 33 resins will reportedly contribute to Decathlon’s environmental mission, deriving 28% of its carbon content from plant sources, while also providing high mechanical properties and optimized clarity in the finished laminates. Formulated with rapid processing in mind, Sicomin says GreenPoxy 33 has been seamlessly integrated into Meditec’s manufacturing process, ensuring it can match Decathlon’s production demand and keep cure cycles as short as 10 minutes at 100ºC.

Meditec combines GreenPoxy 33 with Forest Stewardship Council (FSC) accredited wood cores, further increasing the percentage of responsibly sourced materials in the new JIB and Block boards. Both models, have been designed for intermediate wakeboarders looking for a rigid yet flexible board to be used at cable parks or when towed. The Block model also features a unidirectional (UD) carbon fiber strip on the lower part to further increase its pop on the water.

“The environment is at the heart of our design. It’s a company policy to measure ecological impact yes, but it is also a desire, as outdoor sports enthusiasts, to make products that are as green as possible,” says Gael Gibert, product engineer, Wakeboard, Decathlon. “We are always on the lookout for new technologies that allow us to improve our products in this sense and Meditec and Sicomin have enabled that.”

Decathlon closely monitors all factors that contribute to the ecological impact of its products, including the supply chains and transport miles incurred by both raw materials and finished products. Sicomin’s manufacturing site in southern France, combined with Meditec’s location close to Europe near Tunis, also provides a reliable and low-mileage supply chain that avoids extended shipping from East Asia.

“We are delighted to see Decathlon adding GreenPoxy based boards to their range, reinforcing the fact that more sustainable manufacturing options are just as possible for high-volume production,” adds Sicomin’s Matthieu Chaloin. “We have been working with Meditec for many years now, and their success and expertise in using our GreenPoxy 33 resins for press molded boards makes them the perfect production partner for Decathlon.”

Related Content

-

CirculinQ: Glass fiber, recycled plastic turn paving into climate solutions

Durable, modular paving system from recycled composite filters, collects, infiltrates stormwater to reduce flooding and recharge local aquifers.

-

Hexagon Purus Westminster: Experience, growth, new developments in hydrogen storage

Hexagon Purus scales production of Type 4 composite tanks, discusses growth, recyclability, sensors and carbon fiber supply and sustainability.

-

Recycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.