DLR develops additive WeldSealer process to seal joints, edges or modify surfaces

The robotic process developed for large components protects joints and edges, prevents cracks and allows multipart structures to be created as if cast in one piece.

The DLR Center for Lightweight Production Technology (ZLP, Augsburg, Germany) is advancing automated processes for fiber-reinforced thermoplastic composites in structural applications, including within the LuFo6.1 HoTStufF project and the CleanSky2 MultiFunctional Fuselage Demonstrator (MFFD) project. An innovative example of this is the additive WeldSealer process which applies material onto fiber-reinforced structures with a form-fitting and cohesive connection, but without foreign materials.

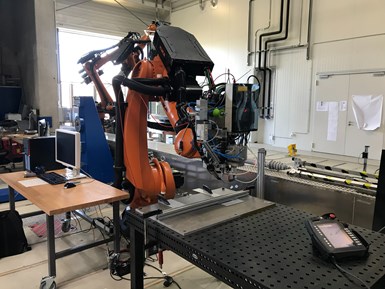

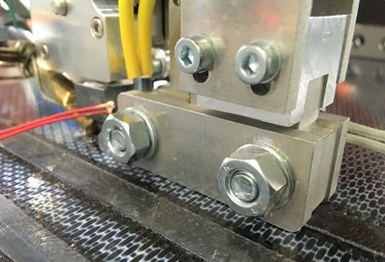

Fig. 1. The WeldSealer process with robotic handling can be applied for treatment of large components. Photo Credit: DLR CC BY-NC-ND 3.0

The process can be automated and applied to seal joints, create defined component edges or modify surfaces. The process is characterized by the manufacture of a precise geometry onto large areas, tool shaping and cooling under pressure.

The WeldSealer end effector comprises a surface preheater, a unit for additive polymer application and a pressure tool for material shaping and consolidation, as well as the material storage. The process requires robotic handling for processing of large and curved parts, as well as solid component fixturing (Fig. 1).

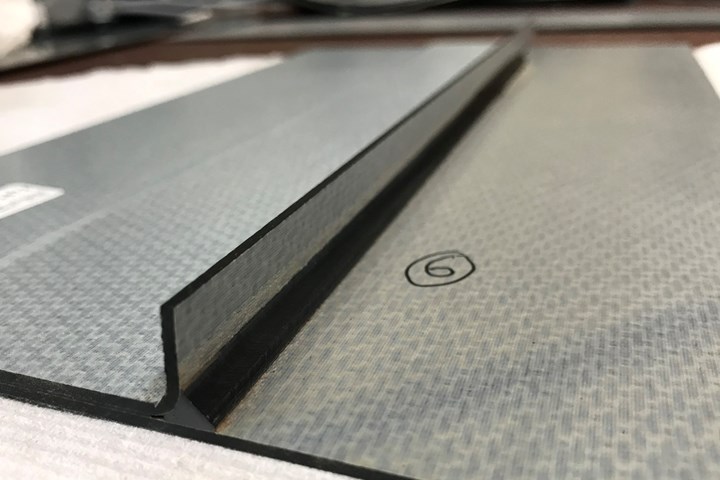

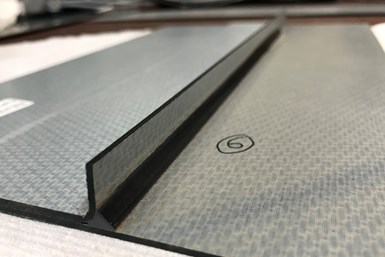

Fig. 2. Sealed carbon fiber-reinforced polyphenylene sulfide (CF/PPS) laminate joint with single overlap configuration and integrated stiffening structure. Photo Credit: DLR CC BY-NC-ND 3.0

Objectives are the modification of laminate-joint edge areas with a gap-free and flowing connection (Fig. 2). This minimizes stress peaks, avoids initiation of microcracks and protects the joint from the influence of various media. Processing with the WeldSealer enables multipart structures to be created as if they were cast in one piece.

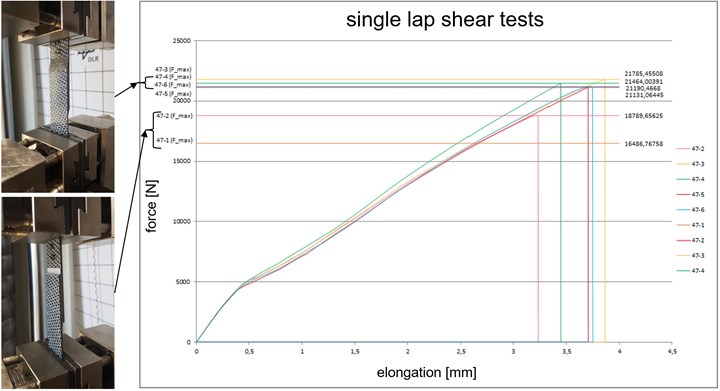

DLR investigations into the process’ influence on mechanical properties show a slight increase in strength, as well as a significant reduction in the standard deviation of the strength test values (Fig. 3). The latter is particularly advantageous, traced back to the defined geometric shape of the joint zone edge areas, where failures usually begin through microcracking.

Fig. 3. Influence on strength and standard deviation in unsealed specimens (bottom sample) and specimens sealed via WeldSealer process (top sample). Photo Credit: DLR CC BY-NC-ND 3.0

Another example application is to use WeldSealer as a pre-processing technique to apply the energy director used for continuous ultrasonic welding (Fig. 4). From an excerpt from “Thermoplastic composites welding advances for more sustainable airframes”:

Fig. 4. Shaping the energy director on laminate surfaces before ultrasonic welding. Photo Credit: DLR CC BY-NC-ND 3.0

Michael Kupke, vice director, Institute of Structures and Design and head of department at ZLP, explains: “In continuous ultrasonic welding, heat is generated when there is damping of the ultrasonic waves. Stiffer materials transmit the waves, while softer materials increase damping. A soft layer of unreinforced polymer — the same matrix as in the composite surfaces being welded — is placed at the weld interface to control the energy during welding. This is called an energy director.”

WeldSealer can also be used to functionalize laminate surfaces in other ways.

DLR is currently exploring alternative energy sources for heating laminate surfaces to increase WeldSealer process speed and is also advancing WeldSealer processing of demanding but relevant high-performance polymers for aerospace structures such as low-melt polyaryletherketone (LMPAEK) on unidirectional (UD) laminates.

Related Content

-

Plant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

-

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.