Dolphitech capability study benchmarks dolphicam2 NDT platform

A CFRP panel was manufactured to the specification of an FAA NDI Proficiency specimen 2A, representative of composite laminates found on commercial aircraft.

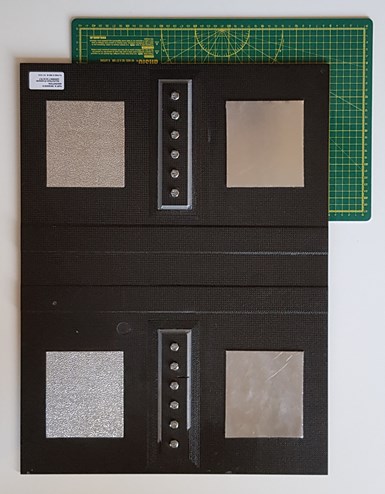

Figure 1. a) Photograph of the bottom face of the panel showing the ply build ups/sound dampers. Photo Credit, all images: Dolphitech

Dolphitech (Gjøvik, Norway) performed a recent capability study to provide insight into how effective the dolphicam2 ultrasonic platform is — a system supporting ultrasonic nondestructive testing (NDT) — when inspecting composites on aircraft. To perform this study, the company used a carbon fiber-reinforced plastic (CFRP) panel representative of the solid laminate composites on commercial aircraft, such as on a Boeing 787 or on an Airbus A350.

The inspection panel used to assess the performance of the NDT equipment was made to the specification of a Federal Aviation Administration (FAA) NDI Proficiency specimen 2A and featured various manufacturing flaws typical of aerospace composites. Specifically, the panel was a 24 ply co-cured substructure (16 ply skin with eight ply stiffeners and built-up pads). The sample was designed to include a wide range of common flaws in this relatively compact inspection sample.

According to Dolphitech, the dolphicam2, used with a TRM-CI-5MHz transducer (TRM), was able to successfully inspect the FAA NDI Proficiency Specimen 2A. All of the manufactured flaws were clearly resolved and characterized. The flaws present included missing sealant, pillow inserts, Dremel cut, flat bottom holes, prepreg backing and grease.

In conclusion, Dolphitech notes that the time and cost savings enabled by the dolphicam2 are demonstrated by its ability to characterize such a wide range of flaw types with a single setup. Similarly, the TRM-CI-5MHz transducer is said to be versatile and well-suited for many aerospace applications featuring thin to moderate thicknesses of both composites and metals.

Contact sales@dolphitech.com to request the full study or it can be accessed online here.

Related Content

-

Photothermal tomography system enhances composites NDT

JEC World 2024: Austria-based voidsy GmbH introduces the 3D V-ROX system, facilitating fast, contactless and nondestructive inspection with added efficiency and safety.

-

VIDEO: AI, cameras and lasers for FOD detection

Virtek Vision demonstrates its Iris AI technology at CAMX 2024. It combines laser projection with machine learning software to detect foreign object debris during a composite layup.

-

Laser NDT, DIC systems demonstrate optimized noncontact composites inspection

CAMX 2024: Dantec Dynamics is presenting three of its laser shearography NDT and DIC devices, geared toward reliable measurement results.