Evonik, Vestaro consortium partners develop EV Pure Performance Battery

Novel approach to high-voltage GF-SMC battery module housing design increases battery cell capacity, enables flexible adjustment of the number of modules and can be catered to a variety of vehicle architectures.

Share

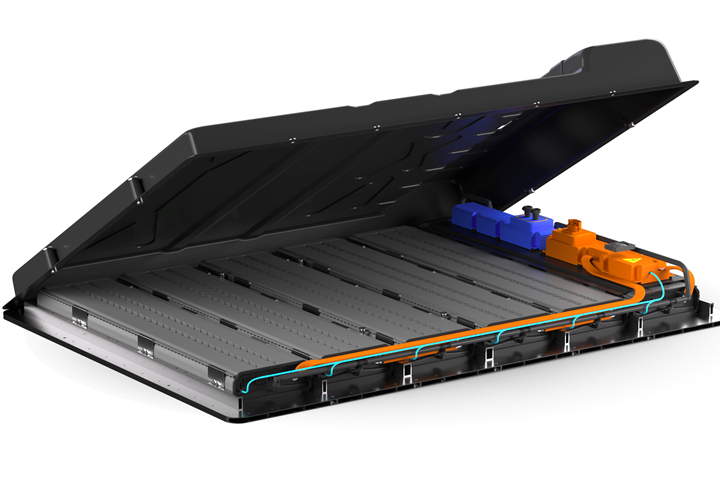

Pure Performance Battery (PPB) open view. Photo Credit, all images: Evonik

Evonik Industries (Essen, Germany), as part of a consortium of companies working to produce lighter, more cost-effective solutions for battery electric vehicles (BEV) using composites (see “Evonik-led group targets epoxy SMC for EV battery housings”), has developed a new generation of battery packs, the “Pure Performance Battery” (PPB). Based on sheet molding compound (SMC) technology made using Evonik’s curing agents, the novel holistic battery system concept is said to provide the automotive industry with a safe, lightweight and cost-effective alternative to traditional metal-based solutions.

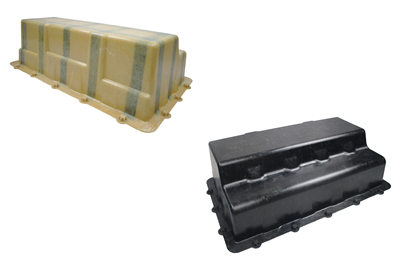

Formed at the end of 2019 to investigate alternative battery solutions, consortium partner Vestaro (Munich, a joint venture of Evonik and Forward Engineering) first developed a glass fiber (GF)-SMC cover based on Evonik’s high-performance epoxy curing agent Vestalite S. In addition to reducing the weight of the battery housing by almost 10% compared to equal-performing covers made from more cost-prohibitive materials, the state-of-the-art SMC materials also deliver the performance levels of previous metal-based enclosures but enable the design freedom for semi-integral integration.

Following the publication of the successful results of Vestaro’s new GF-SMC cover produced by its partner, Lorenz Kunststofftechnik (Wallenhorst, Germany) at the beginning of 2021, the consortium was boosted further when Tier 1 automotive component manufacturer, Minth (Jiaxing City, China) joined. With the additions of Minth’s in-depth know-how for aluminum solutions, the enhanced consortium tackled two major challenges for today’s battery packs: the bottom impact use case and the vehicle integration.

To meet these stringent OEM requirements in terms of side pole, and bottom impact without any leakage or failure, the consortium came up with a novel approach that fully used the design freedom of SMC. The old bottom structure was replaced with an aluminum sandwich plate developed by Minth, which reportedly increases the performance in terms of the bottom impact, but also plays a key role in the semi-integral vehicle concept. With this concept, the consortium was able to remove the additional side deformation elements and use the freed space for more battery cells instead.

PPB side view.

Additionally, due to the improved bottom impact performance of the sandwich floor, the space required for the module mounting could be reduced. The creation of these extra spaces for battery cells has led to an overall capacity increase of 10 kilowatt-hours, from 65 to 75 kilowatt-hours, with nearly the same outer dimensions of the battery pack compared to the group’s previous generation.

“Our new battery pack is designed for performance and it’s the exceptional properties of our Vestalite curing agents that give the epoxy-SMC cover its outstanding performance and safety potential in terms of fire resistance and crash behavior,” says Sebastian de Nardo, marketing director for adhesives and composites at Evonik. “We’ve successfully overcome all concerns regarding the EMI shielding performance of the glass fiber composites using Evonik’s broad material toolbox and expertise, and we can tailor the PPB’s performance to meet each customer’s individual requirements.”

Designed and validated using Forward Engineering’s BEV floor structure development tool, the PPB is around 2.1 meters long x 1.58 meters wide with maximum heights between 0.15-0.22 meters (Penthouse architecture) and is suitable for a variety of vehicle architectures. In terms of weight, the GF-SMC cover-based PPB is said to compete with other high-end solutions but delivers a significant increase in performance.

Additionally, the battery’s semi-integral modular series design enables flexible adjustment of the number of modules, and the production of complex geometries in a one-step process enables tailored battery performance levels to suit all regional requirements. The supercell concept is based on Lion Smart’s (Garching, Germany) Light Battery, which enables a calculated fast charging result of around 13 minutes with charging power constantly above 200 kilowatts (10-80% SOC). The system is currently being developed with the aim of achieving charging times of less than 10 minutes.

Improving the sustainability of vehicle components is also an important topic for the automotive industry, so the new cover has been designed to be easily demounted to provide quick access to battery modules and peripheral equipment. Additionally, the cover itself can be recycled via Lorenz Kunststofftechnik’s recycling process and used again for new composite parts.

Additional “mix-and-match” services to cater for other potential customer requests are also possible through the Vestaro consortium partners.

Related Content

Aviation-specific battery system uses advanced composites to address electric, hybrid flight

BOLDair’s composite enclosure, compression structures and thermal runaway management enables high-performance electric energy storage.

Read MoreComposite wrap system combats corrosion in industrial tank repair

A fiberglass and carbon fiber composite wrap system enabled an Australian nickel mine to quickly repair a stainless steel ammonium sulphate feed tank and protect against future corrosion.

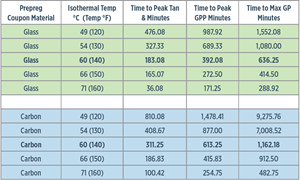

Read MoreReal-time assessment of thermoset composites curing

The combination of material state management (MSM) software and an encapsulated sample rheometer (ESR) enables real-time cure recipe management or cure model development inside the autoclave.

Read MoreACI publishes code requirements for GFRP rebar

New comprehensive building code requirement covers the use of nonmetallic, GFRP reinforcing bars in structural concrete applications that are covered by ACI 318-19.

Read MoreRead Next

Multi-material toolbox for cost-effective, scalable EV battery enclosure design

Mexico-based automotive Tier 1 Katcon has developed a “toolbox” of material, process and joining options aiming to serve a range of electric vehicle requirements.

Read MoreProtocol aims to improve testing of thermal runaway for composite EV battery enclosures

Hyundai-Kia and Forward Engineering developed a resistive, heater-based material test, recently published as a UL standard, to aid and speed composite battery enclosure development.

Read MoreSMC material configurations tailored to automotive battery enclosure design

SMC battery cover offers various module configurations, levels of performance, mass and cost for electric vehicles.

Read More

.jpg;maxWidth=300;quality=90)