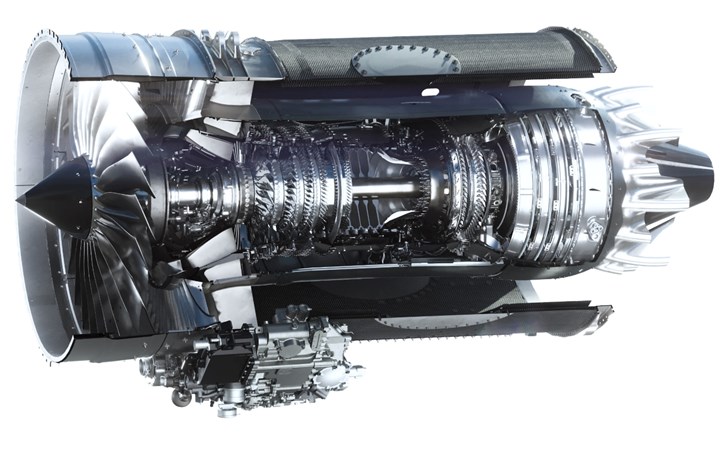

FACC secures composite components project for Rolls-Royce Pearl 10X engine

Under the new contract and readmittance to Rolls-Royce high-performing supplier group, FACC will be supplying bypass ducts, maintenance doors, fan track liners, the spinner and cable bushing.

Photo Credit: FACC AG

FACC AG (Ried im Innkreis, Austria) has been commissioned by Rolls-Royce (London, U.K.) with the development and manufacture of composite components for the new Pearl 10X engine. The aerospace group is represented on the newly launched engine and aircraft platforms as a technology partner.

FACC will be contributing its long-standing know-how of innovative lightweight engine solutions to the design of engine. In addition to the bypass ducts and maintenance doors, the company will be supplying the fan track liners, the spinner and the cable bushing. Rolls-Royce has used FACC’s products in the production of its engines for civil aviation for more than 20 years.

“With the Pearl 10X, Rolls-Royce is offering the business aviation market a groundbreaking, high-performance engine. The fact that Rolls-Royce has selected us as a technology partner for its new premium product once again confirms our leading position in the field of lightweight solutions for aircraft engines,” emphasizes Robert Machtlinger, CEO of FACC AG.

Rolls-Royce officially unveiled the Pearl 10X, reported to be the third and most powerful member of the Pearl engine family for the business aviation market, in early May. Compared to the previous generation of Rolls-Royce engines for business jets, the Pearl 10X boasts a 5% increase in efficiency combined with excellent noise and emissions characteristics. Nacelles will be provided by Spirit AeroSystems (Wichita, Kan., U.S.).

“Engines are among the most highly stressed, high-performance aircraft components — the production of their component parts is highly complex and requires the skill of experienced experts,” says Günter Nelböck, vice president engines & nacelles and aerostructures of FACC. “The production of the outer skin in particular, i.e., the outer layer of the bypass duct for the Pearl 10X, calls for the highest precision in addition to state-of-the-art manufacturing processes. FACC’s performance and excellent customer support play a key role in meeting the customer’s expectations.”

As a confirmation of its innovative lightweight solutions and its 100% commitment to “Best Quality – On Time,” FACC has once again been admitted to the exclusive “Rolls-Royce High Performing Supplier Group.” FACC is part of a select handful of companies to have been a member of this exclusive group of supplier partners since it was created in 2019.

Related Content

-

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

-

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

-

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.