FIBRESHIP demonstrates ship hull section built in fiber-reinforced composite

EU-funded project aims to replace steel in ships, reducing weight, fuel consumption and carbon emissions.

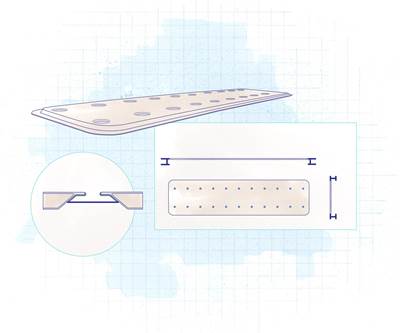

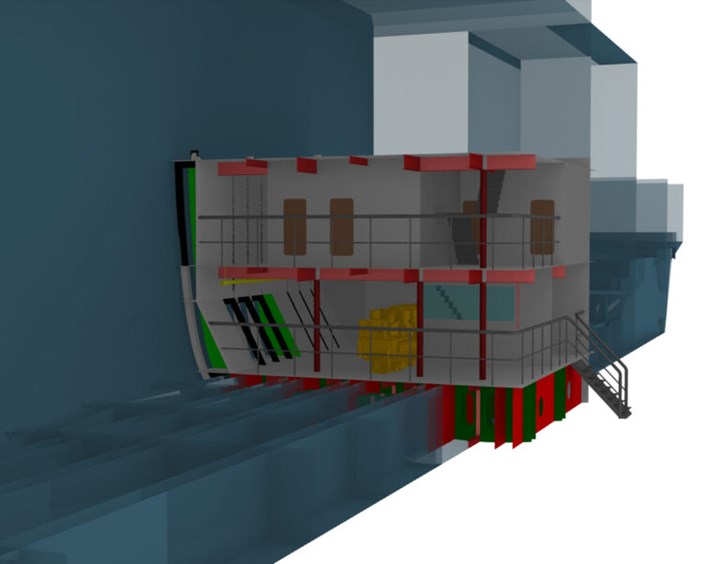

The FIBRESHIP project consortium held its second public workshop in June 2019 at partner company iXblue shipyard in La Ciotat (Marseille, France). There, it presented a demonstrator, a hull section of a fishing research vessel built using a variety of fiber-reinforced composites. The 20-tonne section measures 11 meters by 11 meters by 8.6 meters and the different composites were chosen by structural requirements. This demonstrator will allow verification of design analyses and also final testing.

FIBRESHIP’s main objective is to overcome current technical and regulatory challenges in using fiber-reinforced polymer (FRP) composites to replace steel in conventional shipbuilding of large. This effort is proposed as the best alternative to guarantee the sustainability and competitiveness of the European shipbuilding industry. The project also allows optimization of the maritime transport market, including reduced fuel consumption and emissions.

Demonstrator for industrialized composite construction

Construction of the demonstrator began in late 2018 at iXblue shipyard, which specializes in composite shipbuilding. The result of several studies and experimental tests with different types of resins and fibers, the demonstrator aims to find the most suitable materials and structural connections for FRP ship construction. It seeks to establish both the technical and economic feasibility of such construction through development of methodologies that are readily industrialized.

In parallel, FIBRESHIP has already developed a methodology for material selection and has carried out verifications for mechanical properties, fatigue behavior simulations and small-scale fire tests of the proposed materials. High-precision calculation software has also been designed to aid the structural design, taking into account both static and dynamic forces.

Scheduled to end by May 2020, the FIBRESHIP project includes a study of:

- Production and development of modular assembly techniques in existing shipyards and their adaptation to this technology;

- Development of long-term structural health monitoring and damage control strategies;

- Development of inspection, repair and maintenance procedures;

- Management analysis of waste generation, life cycle and dismantling of large-length vessels.

The demonstrator integrates most of these advances. After its validation is completed, FIBRESHIP aims to confirm the feasibility of FRP composite construction in three categories of vessels measuring more than 50 meters in length considered as the most promising for the shipping sector in the future:

- Lightweight commercial vessels of 240 meters length;

- Passenger transportation and leisure vessels such as a ROPAX of 230 meters in length;

- Special service vessels, such as a fishing research vessel of 85 meters length, which has been used for the demonstrator design.

Addressing regulations

The FIBRESHIP consortium has been working for almost two years to develop a framework for the design, construction and operation of large-length FRP vessels. “It is a major technical and regulatory challenge,” said FIBRESHIP coordinator Alfonso Jurado, “that will set the future of the European shipbuilding industry by combining technology, innovation, sustainability and acceptance by the market.”

Specific regulations are being drafted by partner European classification societies (Bureau Veritas, Lloyd’s Register and RINA), along with other members of the consortium, with the aim of developing future specific regulations for using composites in large-length vessels.

FIBERSHIP will present its results with the RAMSSES project to the International Maritime Organization (IMO) with the goal of showing the viability of this technology in the naval sector and to promote modification or adjustment to current SOLAS regulations.

Innovation with multiple benefits

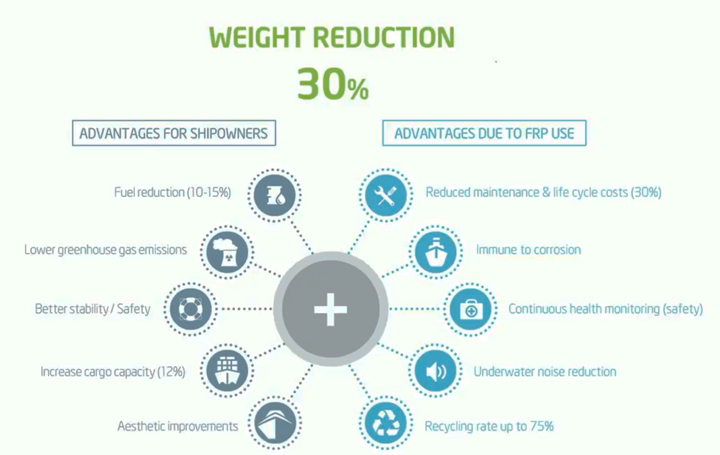

Important benefits that the use of FRP will bring to the shipbuilding and maritime transport sector include:

- A significant structural weight reduction that implies fuel savings and a reduction in greenhouse gas emissions, thanks to a reduction in the power capacity.

- A better performance of the life cycle and lower maintenance costs due to the absence of corrosion.

- Improvement of underwater acoustic signature and less vibration propagation.

- Creation of a new shipbuilding market, allowing European countries to uphold their competitiveness against other countries in other continents.

FIBRESHIP is one of the largest research projects funded by the EC in this field, with an estimated total budget of 11 million euros. The international consortium is made up of 18 companies from 11 countries (Cyprus, Denmark, Spain, Finland, France, Great Britain, Greece, Hungary, Ireland, Italy and Romania):

- Four companies specialized in naval engineering and software development for naval architecture

ATEKNEA, COMPASS IS, TSI, TWI - Three of the most relevant European classification societies

BUREAU VERITAS, LLOYD’S REGISTER, RINA - Three medium-sized European shipyards

iXblue, NAVSHIP, TUCO - Four research centers chosen for experience and experimentation skills

CIMNE, SOERMAR, ULIM, VTT - Four relevant shipowners/operators

ANEK, DANAOS, FOINIKAS, IEO

Related Content

Watch: A practical view of sustainability in composites product development

Markus Beer of Forward Engineering addresses definitions of sustainability, how to approach sustainability goals, the role of life cycle analysis (LCA) and social, environmental and governmental driving forces. Watch his “CW Tech Days: Sustainability” presentation.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreRecycling hydrogen tanks to produce automotive structural components

Voith Composites and partners develop recycling solutions for hydrogen storage tanks and manufacturing methods to produce automotive parts from the recycled materials.

Read MoreASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MoreRead Next

Composite radar masts assembled for megayachts

Vabo Composites designs, builds and assembles 10m-tall composite radar masts, improving weight, stability and performance for modern megayachts.

Read MoreLightweight at sea — get on board

Using composites to lightweight ships is gaining momentum. Several groups are available for materials and technology suppliers to join and help develop cost-effective solutions.

Read MoreLow weight on the high seas

A new, award-winning composite shipbuilding material saves fuel, increases car shipping capacity.

Read More