Filament-wound utility poles designed for easier install, more reliable power

Built to bring more reliable power to natural disaster-prone areas, BASF’s glass fiber/polyurethane poles are currently distributed in Japan.

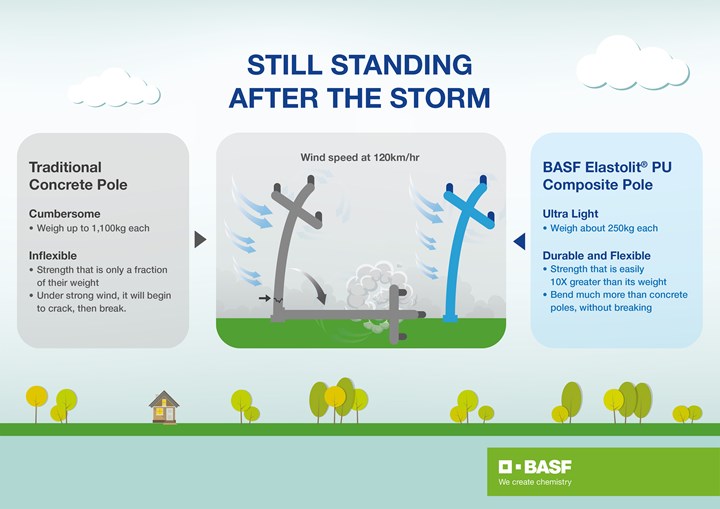

BASF Company Ltd. (Shanghai, China) has announced that its Boldur utility poles, produced via filament winding with the company’s Elastolit polyurethane (PU) and continuous glass fiber, are now available and are being used by a utility pole distributor in Japan. The ultra-light poles are said to withstand severe weather conditions and maintain reliable elictricity supply in areas affected by natural disasters.

Boldur poles, which reportedly weigh only 220 kilograms, are said to have a breaking strength that is 10 times greater than their weight. Similar strength is engineered for other Boldur poles that weigh between 40 and 220 kilograms. BASF says the poles’ strength enables them to stand firm in strong winds during natural disasters and to resist cascades, a phenomenon which occurs when traditional concrete poles fall like dominoes, causing widespread power outages.

“Countries prone to various natural disasters, such as typhoons, floods, and earthquakes, experience heavy property loss and widespread power outages,” says Andy Postlethwaite, senior VP, performance materials Asia Pacific, BASF. “With our strong research capabilities in the compounding of continuous glass fiber and PU materials, combined with a deep understanding of customer needs, we have successfully re-invented the utility poles, making them more lightweight, durable and resilient as compared to conventional concrete ones.”

Source | BASF

Boldur poles are also designed with light weight for easy transport to the job site and installation without machinery, compared to traditional concrete poles that can weigh more than 850 kilograms and require more equipment to move and install.

“During a disaster, Boldur poles can be quickly installed in place of traditional concrete poles, and with less manpower and lifting equipment required. This helps affected neighborhoods to restore electricity more efficiently,” says Larsen Kolberg, head of business management, construction industry, performance materials Asia Pacific, BASF.

Different from wood, steel or concrete poles, Boldur poles are said to be resistant to rust and corrosion and do not require periodic inspections to prevent rotting and insect infestation. Boldur poles are covered in a UV-resistant topcoat for extending their service life. These features help utility operators reduce maintenance costs and extend the life of the power grid.

BASF is currently producing the Boldur poles in South Korea. Boldur poles can be customized in terms of length, strength and stiffness depending on requirements of pole distributors and power providers. The length ranges from less than 8 meters to 12 meters, with mean breaking strengths from less than 4 to more than 20 KiloNewtons (kN). They are also said to be fire-resistant and can self-extinguish quickly.

Related Content

-

Novel composite technology replaces welded joints in tubular structures

The Tree Composites TC-joint replaces traditional welding in jacket foundations for offshore wind turbine generator applications, advancing the world’s quest for fast, sustainable energy deployment.

-

CSub delivers one-piece composite truss bridge in Norway

EPC supplier has fabricated, transported and delivered a 42-meter composite bridge intended for pedestrians and bicyclists.

-

Swedish parking garage to incorporate decommissioned wind blades

Architect Jonas Lloyd is working with Vattenfall to design the multistory building with a wind blade façade, targeting eco-friendly buildings and creative ways to remove blades from landfills.

.jpg;width=70;height=70;mode=crop)