Firefly to become the premier supplier of spaceflight composite components for New Space industry

Negotiating to supply components, such as composite overwrapped pressure vessels (COPV), to external customers, as part of full product line and new space marketplace.

Composite overwrapped pressure vessel tanks produced at Firefly Aerospace. Photo Credit: Firefly Aerospace

Firefly Aerospace Inc. (Briggs, Texas, U.S.), a leading provider of economical and dependable launch vehicles, spacecraft and in-space services, announced the launch of a new line of business dedicated to supplying rocket engines and other spaceflight components — including carbon fiber-reinforced composite structures and composite overwrapped pressure vessels (COPV) — to the emerging New Space industry. “New Space” refers to the recent commercialization of the space sector where private companies such as SpaceX (Hawthorne, Calif., U.S.) now play an ever-expanding role, including launch vehicle development, production and operation, maintenance and supply to the International Space Station (ISS), creation and operation of vast satellite networks, private space travel, manufacturing in space and interplanetary expeditions (e.g., Mars).

“Our goal with this line of business is to become the Tier 1 supplier of components to the New Space industry,” says Tom Markusic, CEO of Firefly Aerospace. “Our component sales business model has inherent advantages over businesses that focus on a single [e.g., rocket engines] or narrow range [e.g., valves] of components.”

The development of this new line of business was born out of the overwhelming interest in Firefly’s technology and the need, within the New Space industry, to shorten the time to market and have a reliable and consistent sourcing partner for the components necessary to develop spaceflight vehicles.

Firefly says it is unique in that it not only builds and operates spaceflight vehicles, such as its Alpha rocket (see “The Alpha launch vehicle: Designing performance in, cost out”), but will also become a premier sourcing partner for other New Space companies to procure the components that are used in those vehicles, helping to lower the barrier to entry in the New Space market. Through the manufacture of its own vehicles, Firefly will establish flight heritage for all components before supplying them to other companies, providing customers with high confidence and low risk, as the components will have been fully proven in spaceflight missions, not just ground tests.

The component business plan also reportedly has the advantage that there is automatically a core customer — Firefly’s spacecraft and launch vehicle divisions. As the company adds external customers, it will allow them to manufacture increasingly larger numbers of the same components, creating economies of scale for production efficiency and cost reduction.

“We initially focused external sales on Firefly’s rocket engines, which we believe provide the best cost/performance in the industry. Initial demand has been strong, with external orders already exceeding the quantity of engines that Firefly was building for use on its own launch vehicle, Alpha,” says Eric Salwan, CRO of Firefly. “Firefly also has strong expertise in the design and production of carbon fiber composite structures. We are currently in active negotiations to supply composite components, such as composite overwrapped pressure vessels [COPV], to external customers.”

While Firefly is launching this line of business based on the components developed in-house, it plans to expand its offerings to include a number of components developed by its partners, creating a new space component marketplace with a complete line of products allowing companies to procure and have components delivered from a single source.

Related Content

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MorePlant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

Read MoreComposites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreRead Next

Firefly Aerospace to automate composite rocket production with Ingersoll AFP machine

The company plans to transition manufacture of its Alpha and Beta all-composite launch vehicles to automated fiber placement starting in 2021.

Read MoreNASA selects Firefly Aerospace for Artemis commercial moon delivery in 2023

Part of NASA's Commercial Lunar Payload Services (CLPS) initiative, Firefly’s Blue Ghost lander will deliver 10 technology payloads to the moon.

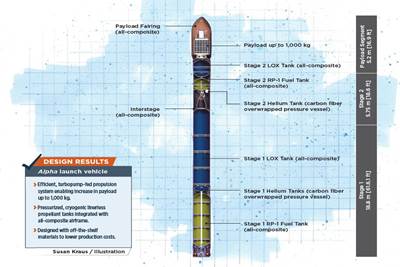

Read MoreThe Alpha launch vehicle: Designing performance in, cost out

Firefly Aerospace’s Alpha 2.0 launch vehicle, designed to deliver satellites into low Earth orbit, gets a composites makeover in pursuit of larger payload capacity and more cost-effective performance.

Read More