Future Composite Manufacturing virtual symposium for AFP and AM

The virtual symposium, held Sept. 9-10, 2020, will focus on current state, trends and opportunities for automated fiber placement (AFP) and additive manufacturing (AM).

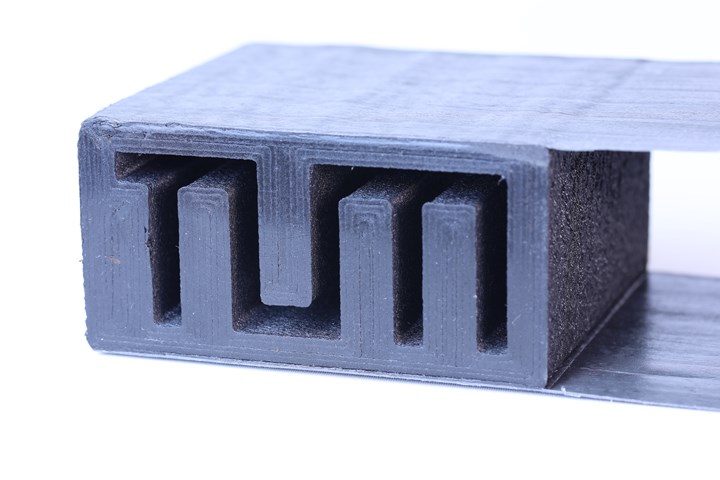

A demonstrator part combining AFP and AM processes.

Future Composite Manufacturing, a virtual symposium on automated fiber placement (AFP) and additive manufacturing (AM), is occurring Sept. 9-10, 2020 from 10:00 – 17:00 (CEST). The symposium is co-hosted by Technical University of Munich (TUM) and Australian National University (ANU), and supported by Composites United, MAI Carbon, one of the largest networks for fiber-based multi-material lightweight construction, and will discuss the current state, trends and opportunities for research and development in AFP and AM.

Some topics include:

- Additive manufacturing with short and continuous fiber reinforcement, automated;

- fiber placement with in-situ consolidation, industrial applications in the aerospace and automotive;

- industries, functionalization and characterization of composites for AFP and AM;

- and simulation of additive processes.

In addition to ANU and TUM, others will be leading the discussions including AFPT, Airbus (Toulouse, France), BMW (Munich, Germany), CEAD (Delft, Netherlands), the German Aerospace Center (DLR; Cologne, Germany), Fraunhofer (München, Germany), INOMETA (Herford, Germany), SGL Carbon (Wiesbaden, Germany) and Victrex (Thornton Cleveleys, U.K.).

Go to the event website to register.

Related Content

-

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

-

Next-generation airship design enabled by modern composites

LTA Research’s proof-of-concept Pathfinder 1 modernizes a fully rigid airship design with a largely carbon fiber composite frame. R&D has already begun on higher volume, more automated manufacturing for the future.