German research team to develop a CNT-based surface heating system for EVs

Collaborative two-year project to study how to apply nanoheating technology to electric vehicle (EV) series production and complex vehicle parts to extend range capabilities.

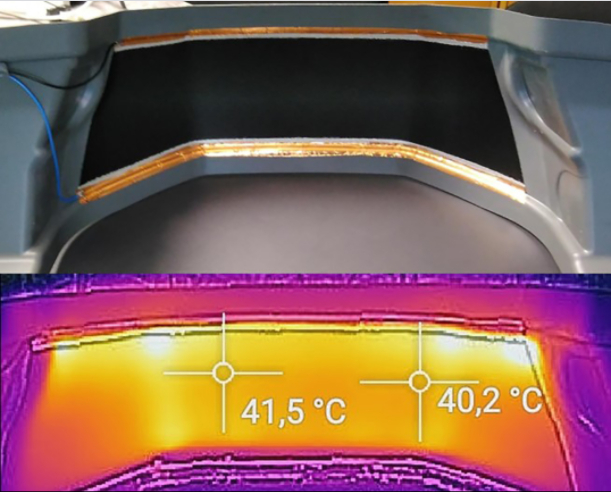

Photo Credit: Osnabrück University of Applied Sciences

It was reported on March 2 that researchers from the Osnabrück University of Applied Sciences (Osnabrück, Germany) are to support solar energy equipment suppler Osnatech GmbH (Bissendorf, Germany) in a two-year project to develop an energy-efficient surface heating system to increase the range of electric vehicles using carbon nanotube technologies (CNTs). With support from the Osnabrück district’s WIGOS Economic Development Corp. and Dr. Daniel Kipp, an innovation consultant from MCON (Oldenburg, Germany), project partners obtained €200,000 funded from the Federal Ministry of Economics.

According to the Federal Motor Transport Authority, the demand for electric vehicles is increasing, with the number of newly registered electric vehicles in Germany having risen by 260% in the previous year. The “Automotive Electrification Index 2020,” observes a similar trend globally. University researchers and Osnatech agree that electric vehicle range is an important aspect in many purchase decisions.

“The heating of the interior is an essential success factor for e-mobility,” emphasizes Prof. Dr. Christian Schäfers, who heads the laboratory for body development and lightweight construction at the Osnabrück University of Applied Sciences. “Anything that limits the range has a negative effect on the acceptance of electric vehicles.” The researcher refers to test drive results by the automobile clubs ADAC and ÖAMTC, which have shown that range can be halved if the temperature outside is around freezing instead of something closer to 20ºC. “The energy-efficient heating of electric vehicles is therefore one of the most important issues for the vehicle industry,” says Schäfers.

Compared to traditional vehicle heating systems, which use wasted heat from the combustion engine and distribute it throughout the vehicle by a fan, e-vehicles work differently. A classic heating fabric or a heat pump is usually used to generate heat, and that costs electricity. “In extreme cases, this means that on long journeys you prefer to turn off the heating and freeze so as not to limit the range of the electric vehicle,” says Andrea Frosch from the WIGOS corporate service. The new heating process with CNTs would be significantly more energy-efficient and potentially more convenient.

“The heating of matter will be using our company’s core CNT technology,” says Bene Nintemann, founder and partner of Osnatech. The specialist from Bissendorf says his company has been developing and manufacturing electrical heating systems based on CNTs for years. Even at lower temperatures, Nintemann says, the CNTs generates a significant proportion of infrared radiation with a lower energy requirement than is possible with traditional materials. This process is already used in building technology; for series production in electric vehicles, however, further development is required.

The most exciting development question for Osnatech then becomes: How can carbon nanotube technology be applied to complex vehicle parts? This is where the laboratory for body development and lightweight construction at the Osnabrück University of Applied Sciences comes into play.

“Electromobility presents us with exciting challenges that need to be solved for the future generations of vehicles,” emphasizes laboratory manager Schäfers. He is pleased to be able to crack this important question together with Osnatech and his creative team. “We all want to be able to say sooner rather than later, ‘it [the electric car] drives and drives and drives.’”

Until the nanoheating is ready for series production, a process is to be developed that applies nanoparticles in a layered structure to the carrier material, such as the body parts, for example. However, it is noted that there are also many other development steps ahead of the partners.

Nintemann adds that he is looking forward to the collaboration: “After a year of intensive preparation, we are very proud that we can tackle this project. This would not have been possible without the active support of Prof. Schäfers with his dedicated team and the financial support from the federal government.”

Related Content

Automotive chassis components lighten up with composites

Composite and hybrid components reduce mass, increase functionality on electric and conventional passenger vehicles.

Read MoreRecycling hydrogen tanks to produce automotive structural components

Voith Composites and partners develop recycling solutions for hydrogen storage tanks and manufacturing methods to produce automotive parts from the recycled materials.

Read MoreComposites end markets: Automotive (2024)

Recent trends in automotive composites include new materials and developments for battery electric vehicles, hydrogen fuel cell technologies, and recycled and bio-based materials.

Read MoreSMC composites progress BinC solar electric vehicles

In an interview with one of Aptera’s co-founders, CW sheds light on the inspiration behind the crowd-funded solar electric vehicle, its body in carbon (BinC) and how composite materials are playing a role in its design.

Read MoreRead Next

CNT-enhanced composite tanks lighten rescue workers' loads

Graphene nanotube-enhanced composite tanks reduce weight in firefighters’ compressed air tanks by up to 75%, and show potential for hydrogen storage.

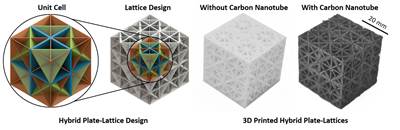

Read MoreCarbon nanotubes functionalize PP, HDPE structures

Using carbon nanotubes, polypropylene, high-density polyethylene and 3D printing, researchers develop a composite with energy absorption superior to that of aluminum.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More