GKN Aerospace and KTH to develop electric fan thruster

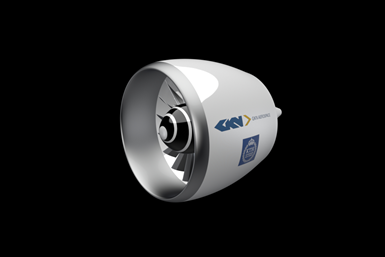

The organizations will work jointly to develop fan technology for smaller regional aircraft. The project will study aerodynamic design, performance, noise and manufacturing technology for a nested fan powered by electricity.

GKN Aerospace (Redditch, U.K.) and KTH (Stockholm, Sweden) — the Swedish Royal Institute of Technology — are jointly developing fan technology for smaller regional aircraft.

The project, which kicked off in July 2021, will study aerodynamic design, performance, noise and manufacturing technology for a nested fan powered by electricity, either from batteries, hydrogen fuel cells or even more conventional hybrid propulsion solutions. The project is supported by the Swedish Energy Agency (Eskilstuna, Sweden).

The proposed propulsion solution, which features a nested fan instead of a conventional propellor, is said to offer significant advantages in safety, noise level and engine installation.

According to GKN, Europe's aviation industry has adopted an ambitious roadmap to achieve net-zero emissions by 2050. Parallel development of different types of propulsion solutions for aircraft engines is one of the important steps to take. GKN Aerospace and KTH hope to make a vital contribution to this technology step.

Henrik Runnemalm, vice president of GKN’s Aerospace Global Technology Centre, says, “We are very positive about this initiative, which helps us to become part of the solution to aviation’s climate challenge.”

Related Content

-

Plant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

-

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.