Graphene-reinforced carbon fibers may offer path to stronger, cheaper composites

Graphene (0.075 weight %) added to PAN precursor exhibited 225% increase in carbon fiber tensile strength and 184% increase in modulus.

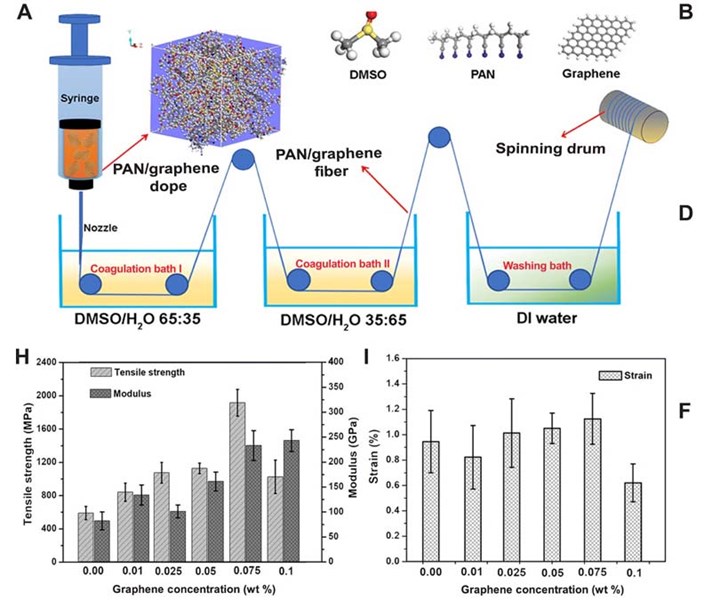

Fig. 1 Illustration of the wet spinning process, microstructure, and mechanical properties of the PAN/graphene composite carbon fibers. SOURCE | “Graphene reinforced carbon fibers” by Zan Gao, et. al., Science Advances.

As published by the Graphene Council, researchers at Oak Ridge National Laboratory (ORNL, Oak Ridge, Tenn., U.S.), University of Virginia (UVA, Charlottesville, Va., U.S.) and Pennsylvania State University (Penn State, University Park, Pa., U.S.) have published research in the April 2020 issue of Science Advances, evaluating the use of pristine graphene as an additive to polyacrylonitrile (PAN) solution for carbon fiber precursor fibers based on previous research using carbon nanotubes (CNTs) and graphene oxide (GO) liquid.

The authors explain how adding CNTs can not only optimize PAN spinning dope and coagulation parameters, but also serve as both the template for the alignment and orientation of polymer chains and the nucleating agent for the polymer crystallization. They cite research by Chae et al. which reported a 49% increase in carbon fiber modulus and a 64% increase in strength with the addition of 1.0 wt % carbon nanotubes. The addition of CNTs have also been shown to lower the carbonization temperature, which can significantly reduce the energy consumption during carbon fiber (CF) manufacturing.

As a single-layered, two-dimensional carbon allotrope, graphene demonstrates superior properties to CNTs, including larger surface area, superior electron mobility, higher tensile strength and Young’s modulus. However, recent experiments using graphene oxide (GO) liquid crystal in the fabrication of carbon fiber, resulted in fibers with subpar tensile strength because of their poor intrinsic alignment and crystallinity.

Theorizing that pristine graphene may be a better additive than CNTs and GO for PAN-based carbon fibers, the ORNL, UVA and Penn State researchers added a small amount of shear-exfoliated pristine graphene (0.01 to 1.0 wt %) to a PAN/dimethyl sulfoxide (PAN/DMSO) solution to fine-tune the properties of the PAN spinning dope. Results showed that PAN/graphene-based carbon fibers with 0.075 wt % graphene exhibited a tensile strength of 1916 MPa and Young’s modulus of 233 GPa — a 225% increase in strength and 184% increase in modulus compared to PAN carbon fibers without graphene.

In addition, large-scale molecular dynamics simulation results show that adding graphene introduces favorable edge chemistry, promotes carbon content, enhances polymer chain alignment and increases crystallinity.

The authors claim these results not only expand the understanding of PAN-based carbon fiber production but also provide a foundation for developing low-cost alternative precursor fibers enhanced by graphene, which may yield carbon fibers that offer superior performance and lower cost to current PAN-based products.

Related Content

-

ASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

-

McLaren celebrates 10 years of the McLaren P1 hybrid hypercar

Lightweight carbon fiber construction, Formula 1-inspired aerodynamics and high-performance hybrid powertrain technologies hallmark this hybrid vehicle, serve as a springboard for new race cars.

-

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.