HAV Hydrogen to introduce containerized H2 system for ships

The standalone, scalable power supply is an option for newly build vessels, or those not already prepared for a conventional retrofit installation below deck, fast-tracking H2 fuel use. HAV notes future opportunities for composites.

Share

Read Next

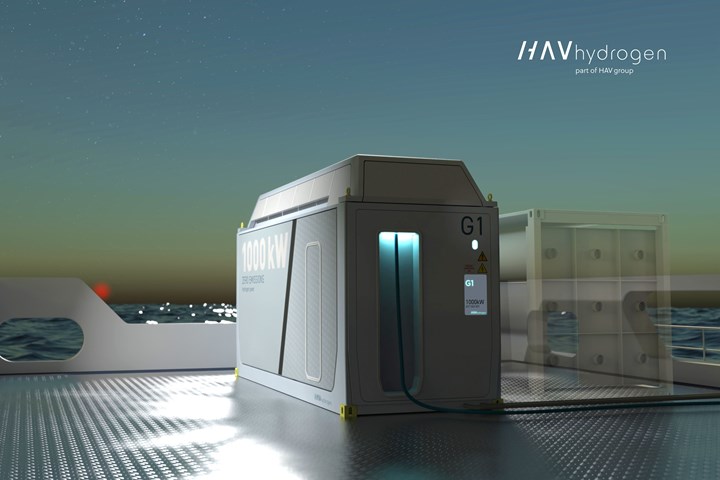

HAV Hydrogen (Fosnavaag, Norway) is set to launch a deck-based containerized hydrogen (H2) energy system for ships in order to fast-track the commercial use of hydrogen as ship fuel. While this system doesn’t currently employ the use of composites, the company tells CW that there is an opportunity in this space for composite H2 storage tanks. HAV Hydrogen expects to seek cooperation with such suppliers in order to present complete solutions for end costumers.

“The containerized, deck-based system is our response to shipowners who want a retrofit option that represents significantly lower cost and risk for vessels that have not already been prepared for a conventional retrofit installation below deck,” Kristian Osnes, managing director at HAV Hydrogen, a system integrator for marine fuel cell solutions, says. “Whereas for new-build vessels it can be a solution that reduces risk and complexity for a technology that is new to most shipyards.”

HAV Hydrogen’s containerized solution is a standalone, scalable power supply where all support and safety systems, as well as electrical power management, are included. The solution is based on 200-kilowatt hydrogen fuel cell modules and can, for instance, be set up with a 1,000-kilowatt output from a standard 20-foot-long shipping container. By using larger containers, or combining several containers, larger capacity energy systems will also be available.

According to the company, installed effect can be used for the main propulsion systems, or for additional power supply on board the vessel. Output effect will be dimensioned to provide optimal zero-emission power in desired operating situations, sailing patterns and vessel type.

“Our containerized solution can be the quick route to zero emission for many vessel types,” Osnes continues. “It is easy to install and enables the customer a quicker route through the challenging approval process for hydrogen systems and significant risk reduction by obtaining a turnkey solution for a fixed price. This will in turn allow us to utilize different financing models, as we believe this will be necessary to get the zero-emission market up and running.”

As a specialist system integrator for marine fuel cell solutions, HAV Hydrogen says it will offer support to shipowners, ship designers and shipyards to ensure an optimal design, integration and installation process.

The containerized H2 solution is based on the hydrogen-based energy system developed in the FreeCO2ast project, which produced a maritime hydrogen-based energy system with a liquid hydrogen tank below deck. Earlier this year, the Norwegian Maritime Authority and DNV (Bærum, Norway) granted preliminary approval for the below deck system.

Related Content

-

Honda begins production of 2025 CR-V e:FCEV with Type 4 hydrogen tanks in U.S.

Model includes new technologies produced at Performance Manufacturing Center (PMC) in Marysville, Ohio, which is part of Honda hydrogen business strategy that includes Class 8 trucks.

-

Polar Technology develops innovative solutions for hydrogen storage

Conformable “Hydrogen in a Box” prototype for compressed gas storage has been tested to 350 and 700 bar, liquid hydrogen storage is being evaluated.

-

Recycling hydrogen tanks to produce automotive structural components

Voith Composites and partners develop recycling solutions for hydrogen storage tanks and manufacturing methods to produce automotive parts from the recycled materials.