Henkel and BTG Labs partner to establish surface measurement standards

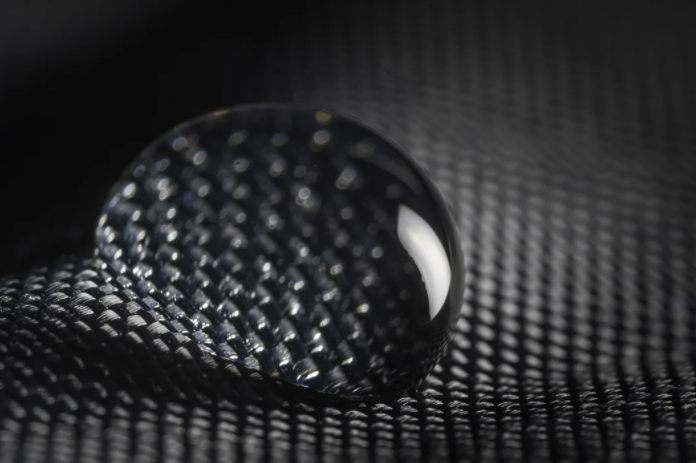

More comprehensive product specifications added to adhesive Technical Data Sheets, including the addition of water contact angles, aids in improving effective bonding results, performance.

Photo Credit: BTG Labs

Henkel (Rocky Hill, Conn., U.S.) and BTG Labs (Cincinnati, Ohio, U.S.) are collaborating to establish more sophisticated guidance regarding surface preparation to maximize the performance of adhesives and obtain effective bonding results. The partnership expects to create “win win” scenarios with customers by updating its technical data sheets (TDSs) to provide clear processing specifications and technical documentation on proper handling techniques.

More specifically, within Henkel’s Loctite product line, three products now have water contact angles (WCAs) included in the Surface Preparation section of the company’s TDSs. WCAs, which are a calculation of surface free energy by evaluating the interface of a liquid and a solid surface are said can consistently provide an objective measurement of whether a surface is properly prepared for adhesive bonding. These products — Loctite Ablestik 8175, Loctite Ablestik CF3350 and Loctite Ablestik 5025E — are used in a variety of applications including solder replacement in microelectronic interconnect applications, electrical, thermal and mechanical assembly applications and bonding “hot” devices onto heatsinks.

Henkel, committed to high-quality standards, says it has implemented rigorous process control to consistently manufacture adhesives that are 100% compliant to internal specifications and that meet the predefined needs of customers. Henkel also understands that even though its products leave the factory floor in a state that is 100% compliant with customer specifications, the steps that are followed in a customer’s production process have an extraordinarily large impact on whether the adhesive performs as intended during production and in the field.

In addition to the inclusion of WCA recommendations for surfaces to the TDSs, Henkel says the are also more comprehensive. Key elements included are:

- Product description

- Technology

- Cure schedules

- Product benefits

- Application notes

- Product compliance to external standards (including MIL-STD-883, Method 5011)

- Typical properties of cured material

- Typical performance of cured material

- General information which includes thawing, surface preparation, directions for use and storage.

Henkel notes that other industries including medical, electronics and consumer products have already integrated WCA as the measurement standard and have also included surface preparation specifications into their TDSs to promote consistent, effective adhesive bonding throughout their manufacturing processes. Specific industry examples include automotive bonding and sealing applications, structural bonding of aircraft, uniformity of coatings on medical tubing and coatings for consumer electronic devices.

Further, Henkel says, manufacturing industries involved in adhesion can benefit from including a WCA specification on TDSs. These benefits include:

- A strong corporate reputation for providing reliable products that perform consistently and are manufactured to precise product specifications.

- Developing an appreciative customer base who recognize the value of not spending time investigating “root causes” of adhesion failures.

- Driving down claims for waste that customers might have erroneously charged a company with because they did not fully understand “best practices” for handling a product during the production process.

- Benefit a company’s technical support staff, who will have more time to spend developing new customer relationships (as opposed to spending time training and retraining the existing customers).

“As a result of including WCAs on the Henkel Technical Data Sheets, we have seen a strong uptick in customer satisfaction and a marked decrease in technical support tickets for these products,” says Doug Katze, market segment manager, Defense and Space, Henkel Corp. “This initiative has been so successful that we plan to include WCAs on more of our Technical Data Sheets.”

Related Content

A new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreCarbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Read MoreSulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MoreRead Next

Porosity, voids and bridging in prepreg autoclave and vacuum bag-only laminates

Consideration of materials, methods and systems explores ways to reduce potential surface porosity, voids, resin-rich areas, bridging and other flaws in composite laminates.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More