Heraeus Noblelight CAE technology aids NCC composites research project

CAE work to determine the precise positioning of IR modules during prepreg layup results in IR system installation at the NCC.

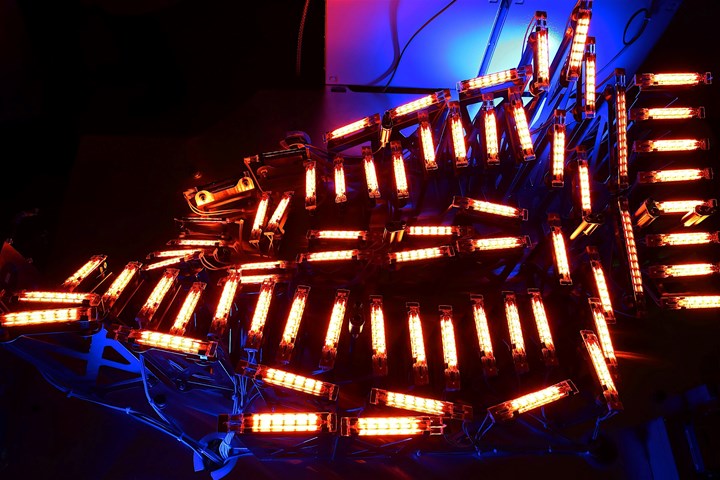

Photo Credit: Heraeus Noblelight

The National Composites Centre (NCC, Bristol, U.K.) is reported to be using sophisticated computer-aided engineering (CAE) technology from Heraeus Noblelight Ltd. (Cambridge, U.K.) to optimize the thermal input and control necessary for selected composite prepreg layup operations, particularly in determining the precise positioning of infrared (IR) modules during this layup process. For select composites applications, it is important to maintain uniform and precise application of heat to prepreg layers for optimal deposition, necessary for high-integrity composite structures.

The NCC, well-versed in the composites industry, brings together and develops minds and technologies, to solve some of the world’s most complex engineering challenges. Through innovation and collaboration, its purpose is to accelerate the commercial adoption of high-impact, sustainable engineering solutions in composites by being the catalyst to enhance U.K. capabilities and stimulate global growth.

To meet its project needs, the NCC collaborated with Heraeus Noblelight, which specializes in the use of simulation and CAE featuring ray tracing and computational fluid to describe and understand the behavior of complex systems using mathematical models, programs and computers.

Heraeus’ first task was to carry out a reflection measurement of the composite to establish the material property for the subsequent optical simulation. The product CAD files were imported with a wireframe representation of the desired heating zones. IR emitter models were then placed in the simulation model and irradiance detectors assigned to the different facets of the simulation model. Next, the optical material properties of all objects in the model were established, including reflection, transmission, absorption and surface scattering. From there, the irradiance at all points on the product surface was simulated by ray tracing and optimization of the simulated setup was carried out by varying the heated length, location and orientation of the emitters, in order to achieve the required homogeneity throughout the target area with the minimum number of emitters.

Following Heraeus’ CAE work, an IR system using fast-response medium wave emitters was installed in a specially built tool at the NCC. This consists of six separate zones, where each zone is PID-controlled and the local surface temperature is measured by a pyrometer.

The IR system is currently in use. As Richard Entwistle, the NCC project leader, notes, “We were impressed with the work carried out by Heraeus, both in their CAE expertise and the quality of the emitters supplied.”

Related Content

-

Bio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

-

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.