Hi-DEN project targets novel high-pressure hydrogen storage innovations

Carbon ThreeSixty, alongside partners Antich & Sons and Viritech, will manufacture, integrate and demonstrate a volumetrically efficient composite hydrogen system for land transport, short-haul aerospace.

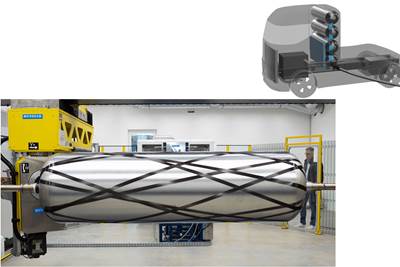

Hi-DEN storage systems. Photo Credit, all images: Carbon ThreeSixty

Carbon ThreeSixty (Chippenham, U.K.), a turnkey provider for the design, development and manufacture of highly challenging, advanced composite structures, is leading a project to develop a novel high-pressure hydrogen storage solution for use with fuel cell systems for land transport and short-haul aerospace.

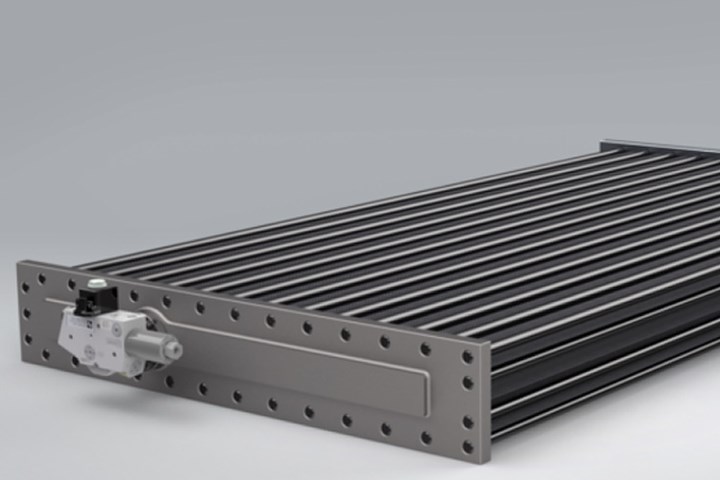

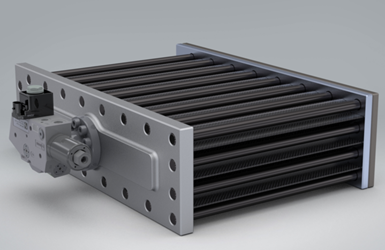

The company’s high-density energy network (Hi-DEN) system will be based on volumetrically efficient arrays of “micro” hydrogen vessels to increase storage capacity, efficiency and vehicle range; essentially, the system is a vessel itself, made up of a connected series of smaller tubes. The idea is that Hi-DEN can be reconfigured depending on available space, Carbon ThreeSixty told CW. At present, the company has focused on making the system fit the underfloor space typically used for battery boxes, but it could also be shaped to fit front/rear compartments, where engines or fuel tanks would typically go. It could also work in the roof spaces used on buses.

Through this volumetric efficiency, storage volume is said to increase by up to 50% for irregularly shaped spaces, such as those typically used for vehicle petrol or diesel tanks, versus larger-diameter conventional composite-overwrapped pressure vessels (COPVs). Hydrogen capacity is eminently scalable, the company notes, but when compared to three conventional COPVs, for example, Carbon ThreeSixty expects to store 15-20% more hydrogen.

The system also offers improved gravimetric efficiency (kilogram/hydrogen, kilogram/structure), hence additional capacity and vehicle range do not come with a corresponding weight penalty. For volume manufacture the cost of hydrogen storage vessels is dominated by carbon fiber cost and “balance of plant” components. Improved material use efficiency therefore enables cost savings in material as well as use of space, Carbon ThreeSixty notes.

In terms of design, at present, each of the company’s mini tubes is required to be the same length. Otherwise, length, width and outer shape profile are flexible. The composite pressure vessel shown at top, for example, is 1.8 × 1 meter and 150 millimeters high.

The Hi-DEN project will build and test a fully functional prototype hydrogen storage vessel. Carbon ThreeSixty is leading the project, completing the design and development of the hydrogen vessel via closed mold resin transfer molding (RTM). Antich & Sons (Huddersfield, U.K.) is responsible for developing 3D woven preforms for the design concept and Viritech (London, U.K.) will develop the tank and fill control system as well as integrate/demonstrate the system in its fuel cell electric vehicle (FCEV) powertrains and provide a route to market.

According to project partners, HiDEN tanks will integrate with standard refueling systems. Carbon ThreeSixty told CW that it will be monitoring temperatures throughout the structure during development to better understand thermal capability. After initial bench/lab testing, vehicle testing with Viritech is planned.

“We’re excited to be leveraging our composite expertise to bring innovation to the gaseous hydrogen storage space and to be able to improve the capability, range and ultimately commercial viability of FCEV vehicles,” Andy Smith, R&D director at Carbon ThreeSixty, says.

The project’s collaborative research and development (R&D) activities have been supported through grant funding provided by Innovate UK, delivered by the Niche Vehicle Network (NVN). NVN is a free-to join-networking and support organization focused on enabling U.K. low-volume vehicle manufacturers and design and engineering companies to research and develop innovative zero-emission vehicle technologies.

Related Content

Honda begins production of 2025 CR-V e:FCEV with Type 4 hydrogen tanks in U.S.

Model includes new technologies produced at Performance Manufacturing Center (PMC) in Marysville, Ohio, which is part of Honda hydrogen business strategy that includes Class 8 trucks.

Read MoreNovel composite technology replaces welded joints in tubular structures

The Tree Composites TC-joint replaces traditional welding in jacket foundations for offshore wind turbine generator applications, advancing the world’s quest for fast, sustainable energy deployment.

Read MoreHexagon Purus opens new U.S. facility to manufacture composite hydrogen tanks

CW attends the opening of Westminster, Maryland, site and shares the company’s history, vision and leading role in H2 storage systems.

Read MoreComposites end markets: Batteries and fuel cells (2024)

As the number of battery and fuel cell electric vehicles (EVs) grows, so do the opportunities for composites in battery enclosures and components for fuel cells.

Read MoreRead Next

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreTU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More