Isoco, V Frames, Lehvoss introduce recycled, biopolymer composites to bike frames

Bio-based, performance-optimized composite materials promote more lightweight, stiff and impact resistant E-bike frames and components.

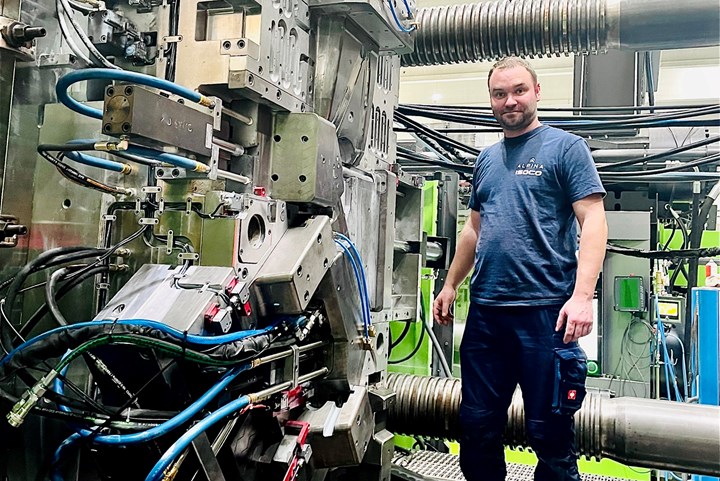

Isoco Bikes (Saalfeld, Germany), an E-bike manufacture producing high-performance injection-molded carbon fiber bike frames, and plastic fabrication company V Frames (Schmiedefeld) have signed an exclusivity agreement with Lehvoss Group (Hamburg) to introduce high-performance fiber-reinforced compounds, including long carbon fiber and biopolymer carbon fiber composite materials, into bike frame and component production.

Per the agreement, V Frames expects to enter mass production of injection-molded carbon fiber composite frames, forks, cockpits and other components for several OEMs by 2027, targeting volumes of 1 million components produced at the Isoco plant in Schmiedefeld, Thuringia. After this, the primary focus is to increase the performance of raw materials to achieve future frames that are more lightweight, impact resistant and feature an increased elastic modulus of up to 50,000 MPa long term (compared to the current 32,000 MPa), further increasing stiffness.

V Frames claims that it already produces some of the most sustainable bike frames on the market, reducing the carbon footprint by 64% compared to traditional aluminum frame production according a life cycle analysis (LCA) performed by the University of Linz, Austria.

V Frames and Lehvoss focus on compounds containing recycled fibers from different industries for new frames, and then recycle its products 100% at the end of their lifetime into new bike component products, providing complete circularity. Production is located in Germany. Isoco’s current production capacility is around three million frames per year.

“Lehvoss is an excellent partner for the development, production and testing of high-performance materials,” Managing Director Michael Müller explains. “With these steps we could push the limits of our technology to new levels. As an example, the Buddy Electric/Isoco X1 frame passed the falling mass test with 23 kilograms at a drop height of 1,120 millimeters, a level far beyond the maximum test requirements of any institute and unreachable by most aluminum and traditional carbon [fiber] frames.”

He says the material used for these high-performance frames is now available for third parties. Additional materials are now being developed and in testing, such as what is contended to be the world’s first bio-based long carbon fiber material for water injection technology [WIT] assisted injection molding.

“Together, we now also push the limits of environmental sustainability with introducing bio-based polyamides reinforced with carbon fibers,” Müller continues. “We are excited to show the results of the new materials in the performance of our frames and components in the next months and years. The approach of V Frames is to provide the perfect material for any frame geometry, any component developed by V Frames, tailor made.”

The new materials introduced in the market under this cooperation consist of:

- Bio-based long carbon fiber materials for WIT injection molding.

- Bio-based polyamides (PA) reinforced with short carbon fibers.

- Economical-, ecological- and performance-optimized materials based on PA, carbon fiber and glass fiber compounds.

All materials developed and tested in the cooperation are available for purchase. For details please contact V Frames and Lehvoss. Material data sheets are available on request.

Related Content

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreTU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MoreNatural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More