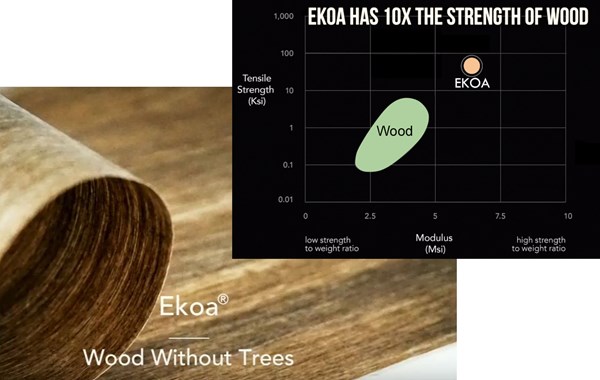

Ekoa TP, better than wood

Flax fiber/bio-thermoplastic composite provide look and feel of wood but higher properties, targeting $80 billion interiors market and, eventually, a wood replacement for construction.

CW has written about Lingrove and its Ekoa products many times, but those were thermoset prepregs and panels using flax fiber and bio-epoxy resin. The company has now launched Ekoa TP, using a lignin-based thermoplastic for industrial-scale fast processing and recyclability in a structural composite that delivers the look and feel of wood but with much better sustainability.

|

|

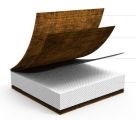

Lingrove develops, sells and distributes plant-based fibers and resins. Its Ekoa flax/bio-epoxy prepreg offers lower density than carbon fiber as well as high-strength, vibration damping and aesthetic appeal. SOURCE: Lingrove

Better than wood

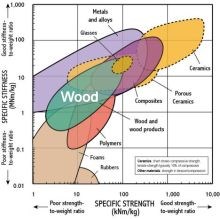

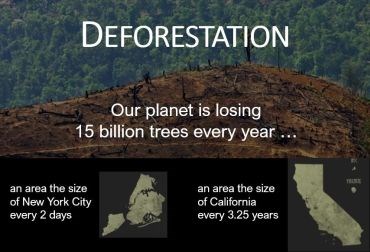

Wood is nature’s structural composite, a strong yet lightweight material composed of cellulose fiber held together by lignin, a natural polymer. In terms of specific strength and stiffness, wood approaches composites and metals, and it remains the material of choice for furniture, homes and interiors. However, its sustainability is increasingly an issue:

- 87% of old growth forests are gone.

- Deforestation is one of the world’s largest environmental problems, and not just in developing countries — Sweden, Finland and Portugal rank in the top 10 nations with most trees lost from 2000-2012

- It is estimated that deforestation is responsible for ≈20% of greenhouse gas emissions.

Wood has very good strength and stiffness at relatively light weight (low density) but it actually is it not a sustainable resource at the current global rate of consumption.

SOURCE: http://www-materials.eng.cam.ac.uk/mpsite/interactive_charts/spec-spec/basic.html (left), CW’s interpretation from www.eco2greetings.com and www.infographicsly.com (right).

Trees require 25-100 years for growth and densification into a structural material. Flax grows in 100 days, requires no irrigation and is CO2 negative. Canada grows 1 million tons of flax per year for the seeds and throws away the stalks. But Lingrove plans to use these stalks, working with an already industrialized global supply chain that produces high-strength, lightweight continuous natural fibers. Lingrove then blends these natural fibers with a bio-based resin made using lignin that is from non-food sources and recyclable. The result is Ekoa TP.

Flax fiber is sustainable, CO2 negative and already produced as a continuous, high strength-to-weight composite reinforcement fiber. SOURCE: Lingrove.

New composites, new applications

Ekoa TP is a continuous fiber-reinforced thermoplastic roll good. Once cut and layered in a mold, it becomes a structural composite material easily compression molded into 3D shapes. The sink below was made for one of the largest interiors fixtures companies in the world. “We are trying to extend the benefits of composites outside of its historical applications,” says Lingrove founder Joe Luttwak.

Ekoa TP offers 3D moldability via a fast-processing yet sustainable structural composite.

SOURCE: Lingrove

Luttwak got his introduction to composites while working in design for Ferrari. He then went on to found Blackbird Guitar, building beautiful instruments with the lightweight and performance of carbon fiber but the look and sound of wood. These materials also provided better resistance to humidity and temperature and no longer helped to fuel the $50 billion black market for poached old growth woods like rosewood and mahogany.

Through years of developing and refining this bio-based composite technology, Luttwak created Lingrove to expand applications for Ekoa. This he has achieved, as illustrated in the examples at top, but then ran up against the issue of scalability. “We could see how thermoplastics offered fast processing and also easier recyclability,” Luttwak notes. “Interiors and furniture manufacturers want materials that process at an industrial scale like plastics, but consumers want the look and feel of wood, as well as products that help prevent the planet’s destruction, not contribute to it. Ekoa TP offers both.”

Lingrove has a letter of intent (LOI) and ongoing development with Steelcase (Grand Rapids, MI, US), the largest commercial interiors company in the world. “We are also selling pilot quantities to several of the largest furniture companies as well as into automotive interiors,” Luttwak adds. Ultimately, Lingrove will offer products for the $150 billion construction market. “Composites are just emerging here, but 37% of global CO2 emissions are from residential and commercial construction. This is a market where we can make a difference while delivering desired performance and aesthetics.”

Products and scaling production

In addition to continuous rolls (hundreds of feet) of consolidated sheet, Ekoa TP will also be sold as structural panels, with a variety of core materials available, ranging from end-grain balsa and foam cores already widely used in composites, to materials more familiar in construction and interiors such as polyurethane foam and cardboard honeycomb. Lingrove is also working with novel bio-based cores.

The company has patented its technology for making natural fiber structural panels and materials, and is currently developing its continuous sheet production capacity, aiming for initial production of 5,000 ft/day by the end of 2018 and scaling to 10,000 ft/day in early 2019.

“Composites have to do their part beyond just lightweight,” says Luttwak. “It’s time to look at materials that reduce not only waste, transportation and lifecycle costs but also address energy usage, emissions and the stimulus for destructive global trends like deforestation.” As world population swells and the construction industry responds, with a projected doubling in size, Ekoa TP composites present a real opportunity.

Axia Materials has trialed Lingrove’s Ekoa TP (top) as a potential material for its Pixel Haus products, seen here in a housing project recently completed in South Korea.

Read “Thermoplastic composite panels deliver affordable housing solutions”.

SOURCE: Axia Materials, Pixel Haus.

Related Content

Composites-reinforced concrete for sustainable data center construction

Metromont’s C-GRID-reinforced insulated precast concrete’s high strength, durability, light weight and ease of installation improve data center performance, construction time and sustainability.

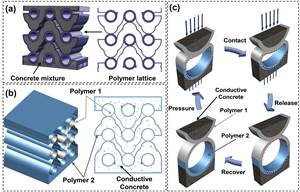

Read More21st century concrete: composite metamaterial with super compressability, energy harvesting

Material comprising 3D-printed, auxetic, reinforced polymer lattices in conductive cement matrix can compress up to 15% and generate electricity for lightweight, mechanically tunable structures with energy harvesting and sensing.

Read MoreCirculinQ: Glass fiber, recycled plastic turn paving into climate solutions

Durable, modular paving system from recycled composite filters, collects, infiltrates stormwater to reduce flooding and recharge local aquifers.

Read MoreComposites end markets: Infrastructure and construction (2024)

Composites are increasingly used in applications like building facades, bridges, utility poles, wastewater treatment pipes, repair solutions and more.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More