Lingrove’s eco-friendly Ekoa composite materials target furnishings and interactive applications

Ekoa, comprised of plant-based fiber reinforcements and resins, achieves cosmetic, structural durability and elegance for a range of interior, furniture and transportation applications.

Photo Credit, all images: Lingrove

Lingrove (San Francisco, Calif., U.S.), a materials and design firm focused on plant-based fibers and resins, announces new developments using Ekoa, the company’s high-performance, eco-friendly composite materials that incorporate a variety of natural fiber inputs and resin systems depending on application requirements while remaining durable and elegant. According to the company, its materials have a 15% lower density than carbon fiber, with a stiffness-to-weight ratio surpassing that of aerospace fiberglass (E-glass).

The company’s scale up into architecture, design and transportation is driven by plant-based thermoplastics reinforced with natural fibers, typically flax, and produced via continuous, additive processes — conventional thermoplastics and thermosets can also be incorporated where required. These preconsolidated surfaces can be used like a wood veneer or laminate as a cosmetic layer in 2D applications or molded as a lightweight sandwich panel and for 3D applications with substrates, and are offered as prepregs and flax linen dry fabrics. Applications currently range from walls, floors and furniture to automotive interiors; in the future, Lingrove expects Ekoa to act as both the structural and cosmetic surface.

The Ekoa platform is versatile and can be applied to a range of applications, from furniture (top left) to automotive interiors (bottom right).

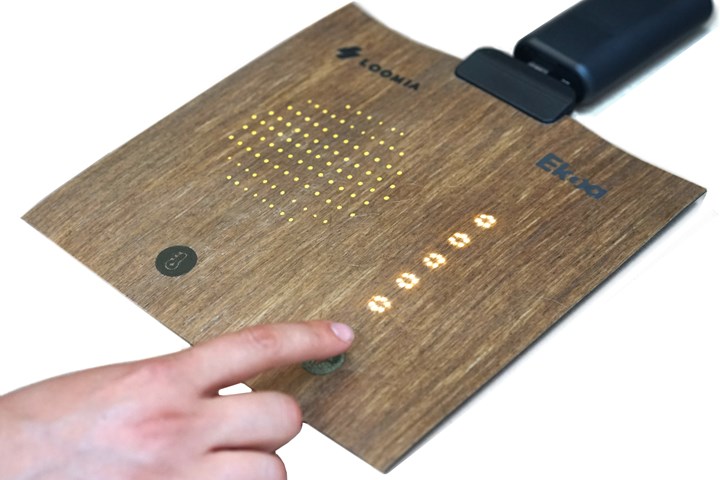

A novel approach includes Ekoa Interactive, which “fuses natural surfaces with digital wizardry,” combining an on-demand electronic interface with Ekoa composite materials. One example (opening image) is a sustainable car dash with a haptic touch control panel housing an interactive display that only appears when needed. When not in use, the high-performance surface reverts to the warm, “carved” wood-like accent offered by Ekoa.

Further, Lingrove is utilizing the Ekoa platform to create exceptionally strong and lightweight 3D structural objects under the Ekoa Surface collection, which targets interior applications and automotive in particular. A functional monitor stand is one successful application example.

Related Content

-

Jeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

-

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.