MAXBlade project to advance tidal energy generation with 13-meter composite blades

Recently launched 66-month MAXBlade project aims to harness tidal energy in the U.K. through a 70% increase in rotor swept area.

Her Royal Highness, The Princess Royal, addresses guests during her visit to FastBlade on Jan. 17. Photo Credit: Neil Hanna

MAXBlade, a €10 million project, funded by the European Union (EU) and UK Research and Innovation, has been launched to deliver a range of innovations to improve the performance of tidal turbines and reduce costs. The project was inaugurated in the presence of Her Royal Highness, The Princess Royal, at the University of Edinburgh’s (U.K.) FastBlade facility, reported to be the world’s first rapid testing facility for tidal turbine blades.

MAXBlade will investigate the full lifecycle of tidal turbine blades, from materials, manufacture and operation, to decommissioning and recyclability. The project’s long-term aim is to ensure the European composite sector becomes the international leader in tidal blade manufacture.

The project plans to increase the area harnessed by Scottish tidal technology company Orbital Marine Power (Edinburgh) to generate power — known as the rotor swept area — by 70%, to more than 1,000 square meters. To achieve this, MAXBlade will increase the length of tidal turbine blades from 10 to 13 meters — making them the longest of their kind. The team says that boosting blade length will have the single greatest impact on reducing the cost of tidal energy.

“This [the MAXBlade project] will help the tidal energy industry to de-risk their ongoing turbine developments and provide low-cost, reliable renewable energy to the grid.”

Modeling by the University of Edinburgh’s Institute of Energy Systems estimates £40 billion could be generated for the U.K. economy by harnessing wave and tidal energy.

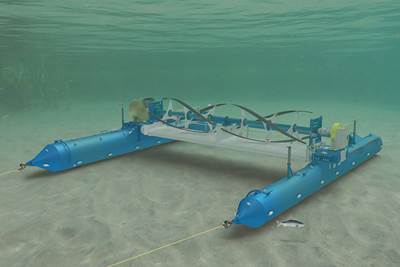

MAXBlade will involve a two-year design and development phase, followed by an 18-month build, during which blades will undergo advanced structural testing at FastBlade. The technology will then undergo two years of real-world testing at the European Marine Energy Centre (EMEC) in Orkney. Two of Orbital Marine Power’s O2 floating tidal turbine platforms will each be fitted with four of the newly developed blades. In total, the project is expected to run from 66 months (January 2023 to June 2028).

The team aims to generate 120,000 hours of performance data that will be assessed by EMEC and project partner Tecnalia (Derio, Biscay, Spain), a research and technological development center.

Innovations from MAXBlade will be integrated with findings from its sister project, FORWARD2030, to enable large-scale production of Orbital’s O2 turbine technology. This will pave the way to the tidal energy sector making significant contributions towards Europe’s energy systems, energy security and industrial development by 2030 and beyond to 2050, the team says.

“The University of Edinburgh is delighted to be a partner in the MAXBlade project, where we will demonstrate the unique rapid testing capability of the FastBlade facility,” Professor Conchúr Ó Brádaigh, head of school and chair of materials engineering at Edinburgh University, says. “This will help the tidal energy industry to de-risk their ongoing turbine developments and provide low-cost, reliable renewable energy to the grid. We will also lead the development of thermoplastic resins in MAXBlade and the circular economy roadmap needed for future tidal blade manufacturing and recycling.”

MAXBlade is led by TechnipFMC and includes Orbital Marine Power, Marasoft, Tecnalia, University of Edinburgh, EMEC, Laborelec and the European Composites Industry Association. It is supported by Edinburgh Innovations, the University of Edinburgh’s commercialization service.

Related Content

Revisiting the OceanGate Titan disaster

A year has passed since the tragic loss of the Titan submersible that claimed the lives of five people. What lessons have been learned from the disaster?

Read MorePro-Set named official materials supplier for New York Yacht Club American Magic

Competitive sailing team prepares for the 37th America’s Cup beginning in August 2024 with adhesives, resins and laminate testing services for its AC75 monohull construction.

Read MoreEvolving natural fiber technology to meet industry sustainability needs

From flax fiber composite boats to RV exterior panels to a circularity model with partnerships in various end markets, Greenboats strives toward its biomaterials and sustainable composites vision in an ever-changing market.

Read MoreNlcomp launches recyclable composite sailing boat Ecoracer30

Italian startup featured its 30-foot sustainable production boat at the Ocean Race Grand Finale in Genoa, Italy, citing the challenges, highlights and future related to its development.

Read MoreRead Next

Éirecomposites and ORPC to use recycled carbon fiber in tidal turbine foils

Development part of €3M CRIMSON project to advance tidal energy for clean electricity.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More