Melt spinning plant installation evolves DITF's fiber development

New melt spinning pilot plant offers a well-equipped environment for the development and application of research into new spinning processes, fiber functionalization and sustainable fibers.

The German Institutes of Textile and Fiber Research Denkendorf (DITF) has modernized and significantly expanded its melt spinning pilot plant with support from the state of Baden-Württemberg. The new facility enables research into new spinning processes, fiber functionalization and sustainable fibers made from biodegradable and bio-based polymers.

In the field of melt spinning, the DITF are working on several pioneering research areas, for example the development of various fibers for medical implants or fibers made from polylactide, a sustainable bio-based polyester. Other focal points include the development of flame-retardant polyamides and their processing into fibers for carpet and automotive applications as well as the development of carbon fibers from melt-spun precursors. The development of a bio-based alternative to petroleum-based polyethylene terephthalate (PET) fibers into polyethylene furanoate (PEF) fibers is also being explored. Bicomponent spinning technology, in which the fibers can be produced from two different components, plays a particularly important role, as well.

Since polyamide (PA) and many other polymers were developed more than 85 years ago, various melt-spun fibers have revolutionized the textile world. In the field of technical textiles, they can have on a variety of functions: depending on their exact composition, they can, for example, be electrically conductive or luminescent. They can also show antimicrobial properties and be flame retardant. They are suitable for lightweight construction, for medical applications or for insulating buildings.

In order to protect the environment and resources, the use of bio-based fibers will be increased in the future with a focus on easy-to-recycle fibers. To this end, the DITF are conducting research into sustainable polyamides, polyesters and polyolefins, as well as many other polymers. Many “classic” polymers — e.g., petroleum-based polymers — cannot be, or cannot easily be broken down into their components or recycled directly after use. Therefore, an important goal of new research work is to further establish systematic recycling methods to produce fibers of the highest possible quality.

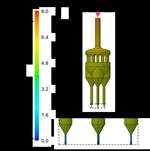

For these forward-looking tasks, a bicomponent spinning plant from Oerlikon Neumag was set up and commissioned on an industrial scale at the DITF in January 2024. The bulk continuous filaments (BCF) process enables bundling, bulking and processing of the (multifilament) fibers, to achieve large-scale synthesis of carpet yarns as well as staple fiber production.

The system is supplemented by a so-called spinline rheometer. This enables a range of measurement-specific chemical and physical data to be recorded online and inline, which will contribute to a better understanding of fiber formation. In addition, a new compounder will be used for the development of functionalized polymers and for the energy-saving thermomechanical recycling of textile waste.

For related content, read “DITF Denkendorf advances sustainable carbon fibers, oxide fibers for CMC and more.”

Related Content

-

Recycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

-

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

-

Novel composite technology replaces welded joints in tubular structures

The Tree Composites TC-joint replaces traditional welding in jacket foundations for offshore wind turbine generator applications, advancing the world’s quest for fast, sustainable energy deployment.