Mitsui Chemicals, Microwave Chemical install demonstration facility for eco-friendly carbon fiber

Microwave-based Carbon-MX process could cut energy consumption by 50% and CO2 emissions by 90%.

Share

Read Next

Rendering of the development facility’s production line. Photo Credit: Mitsui Chemicals

Mitsui Chemicals Inc. (Tokyo, Japan) and Microwave Chemical Co. Ltd. (Osaka, Japan) announced in November 2022 that they will set up a facility to demonstrate basic technology relating to the manufacture of eco-friendly carbon fiber. The demonstration facility is scheduled to be completed by December 2023 and will be located within Mitsui Chemicals’ Nagoya Works.

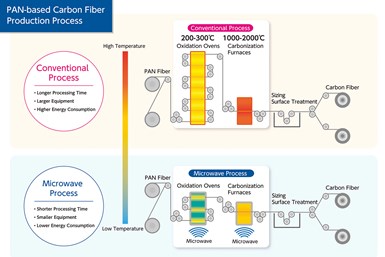

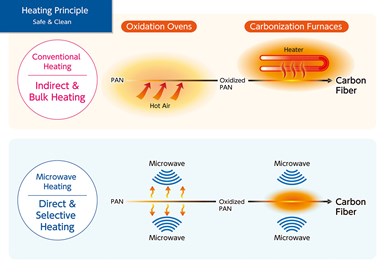

Microwave Chemical reported that it has created an innovative carbon fiber production technology that combines the oxidation process — which it cites as the most energy-intensive part of carbon fiber production — with the carbonization process. This integrated heating process based on microwaves has been named Carbon-MX.

Microwave Chemical will contribute to the installation of the demonstration facility by providing Mitsui Chemicals with all of the necessary equipment for a heating line based on the Carbon-MX technology. Mitsui Chemicals will set up the entire process, including the elements of the process involving this technology. Once construction of the demonstration facility is complete, the companies intend to jointly explore establishing technology for mass production.

The 2022 announcement states:

“By leveraging the ability of microwaves to heat a target substance from the inside, the technology here will enable an innovative process that minimizes unnecessary heat generation. When compared to existing methods, this will significantly reduce the time spent on heat treatment, resulting in a shorter heating process line and thus more compact facilities. Further, since the equipment itself does not reach high temperatures, the technology is expected to provide benefits with regard to equipment costs, energy costs and safety.”

Mitsui Chemicals and Microwave Chemical have projected that this approach will cut energy consumption by 50%. Furthermore, if renewable energy is used to generate the microwaves, CO2 emissions are expected to be reduced by more than 90%.

Photo Credit: Microwave Chemical

The announcement stated that Mitsui Chemicals and Microwave Chemical will employ life cycle assessments (LCA) as they look to minimize the presence of carbon throughout their value chains. The companies will endeavor to meet the rising need for carbon neutrality in industries where carbon fiber is slated for use, including the mobility sector.

Note, the two companies are also jointly working to commercialize a chemical recycling technique that uses PlaWave microwave-based technology developed by Microwave Chemical to directly break down automotive shredded residue (ASR) and sheet molding compound (SMC) products into raw monomers. See the full press release.

Related Content

-

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

-

Composites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

-

Bio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.