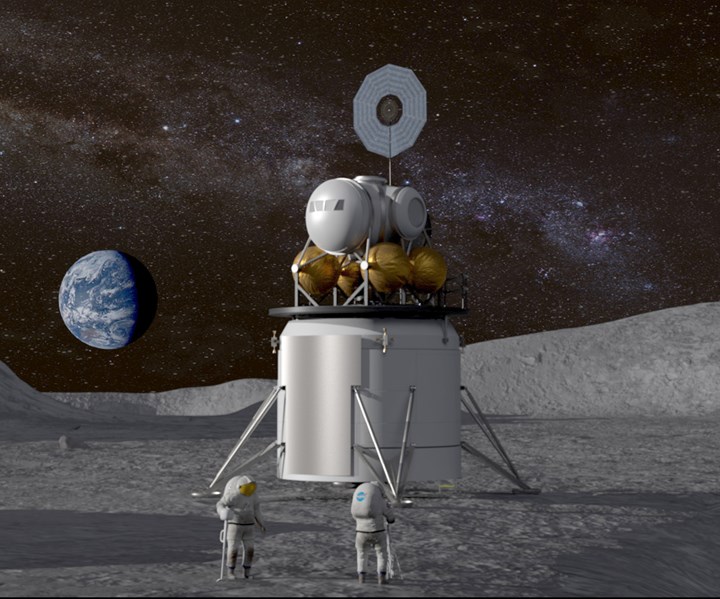

NASA announces U.S. industry partners for Moon, Mars programs

The partnerships will advance the commercial space sector and help bring new capabilities to market that could benefit future NASA missions.

Source | NASA

NASA (Washington, D.C., U.S.) has selected 10 U.S. companies for 19 partnerships to mature industry-developed space technologies as the agency prepares to land humans on the Moon by 2024 with the Artemis program.

NASA centers will partner with the companies, which range from small businesses with fewer than a dozen employees to large aerospace organizations, to provide expertise, facilities, hardware and software at no cost. The partnerships will advance the commercial space sector and help bring new capabilities to market that could benefit future NASA missions.

“NASA’s proven experience and unique facilities are helping commercial companies mature their technologies at a competitive pace,” says Jim Reuter, associate administrator of NASA’s Space Technology Mission Directorate (STMD). “We’ve identified technology areas NASA needs for future missions, and these public-private partnerships will accelerate their development so we can implement them faster.”

The selections were made through NASA’s Announcement of Collaboration Opportunity (ACO) released in October 2018. They will result in non-reimbursable Space Act Agreements between the companies and NASA. The selections cover the following technology focus areas, which are important to America’s Moon to Mars exploration approach.

Advanced Communications, Navigation and Avionics

-

Advanced Space (Boulder, Colo., U.S.) will partner with NASA’s Goddard Space Flight Center (Greenbelt, Md., U.S.), to advance lunar navigation technologies. The collaboration will help mature a navigation system between Earth and the Moon that could supplement NASA’s Deep Space Network and support future exploration missions.

- Vulcan Wireless (Carlsbad, Calif., U.S.), also will partner with Goddard to test a CubeSat radio transponder and its compatibility with NASA’s Space Network.

Advanced Materials

- Aerogel Technologies (Boston, Mass., U.S.) will work with NASA’s Glenn Research Center (Cleveland, Ohio, U.S.) to improve properties of flexible aerogels for rocket fairings and other aerospace applications. The material can result in 25% weight savings over soundproofing materials currently used in rocket fairings.

- Lockheed Martin (Littleton, Colo., U.S.), will work with NASA’s Langley Research Center (Hampton, Va., U.S.), to test materials made from metal powders using solid-state processing to improve the design of spacecraft that operate in high-temperature environments.

- Spirit AeroSystems Inc. (Wichita, Kan., U.S.) will partner with NASA’s Marshall Space Flight Center (Huntsville, Ala., U.S.) to improve the durability of low-cost reusable rockets manufactured using friction stir welding. This welding method, already being used for NASA’s Space Launch System, results in a stronger, more defect-free seal compared to traditional methods of joining materials with welding torches.

Entry, Descent and Landing

- Anasphere (Bozeman, Mont., U.S.) will partner with Marshall to test a compact hydrogen generator for inflating heat shields, which could help deliver larger payloads to Mars.

- Bally Ribbon Mills (Bally, Pa., U.S.) will perform thermal testing in the Arc Jet Complex at NASA’s Ames Research Center in California’s Silicon Valley. The facility will be used to test a new seamless weave for a mechanically deployable carbon fabric heat shield.

- Blue Origin (Kent, Wash., U.S.) will collaborate with NASA’s Johnson Space Center in Houston and Goddard to mature a navigation and guidance system for safe and precise landing at a range of locations on the Moon.

- Sierra Nevada Corp. (Sparks, Nev., U.S.), will work with NASA on two entry, decent and landing projects. The company will partner with Langley to capture infrared images of their Dream Chaser spacecraft as it re-enters Earth’s atmosphere traveling faster than the speed of sound.

- For the second collaboration, Sierra Nevada Corp. and Langley will mature a method to recover the upper stage of a rocket using a deployable decelerator.

- SpaceX (Hawthorne, Calif., U.S.), will work with NASA’s Kennedy Space Center in Florida to advance their technology to vertically land large rockets on the Moon. This includes advancing models to assess engine plume interaction with lunar regolith.

In-Space Manufacturing and Assembly

- Maxar Technologies (Palo Alto, Calif., U.S.) will work with Langley to build a breadboard – a base for prototyping electronics – for a deployable, semi-rigid radio antenna. In-orbit assembly of large structures like antennae will enhance the performance of assets in space. Such capabilities could enable entirely new exploration missions that are currently size-constrained and reduce launch costs due to improved packaging.

Power

- Blue Origin will partner with Glenn and Johnson to mature a fuel cell power system for the company’s Blue Moon lander. The system could provide uninterrupted power during the lunar night, which lasts for about two weeks in most locations.

- Maxar will test lightweight solar cells for flexible solar panels using facilities at Glenn and Marshall that mimic the environment of space. The technology could be used by future spacecraft to provide more power with a lower mass system.

Propulsion

- Aerojet Rocketdyne (Canoga Park, Calif., U.S.) and Marshall will design and manufacture a lightweight rocket engine combustion chamber using innovative processes and materials. The goal of the project is to reduce manufacturing costs and make the chamber scalable for different missions.

- Blue Origin, Marshall and Langley will evaluate and mature high-temperature materials for liquid rocket engine nozzles that could be used on lunar landers.

- Colorado Power Electronics Inc. (Fort Collins, Colo., U.S.) will partner with Glenn to mature power processing unit technology that extends the operating range of Hall thrusters, which are primarily used on Earth-orbiting satellites and can also be used for deep space missions. By integrating their technology with NASA and commercial Hall thrusters, the company expects to provide a propulsion system that can significantly increase mission payload or extend mission durations.

- SpaceX will work with Glenn and Marshall to advance technology needed to transfer propellant in orbit, an important step in the development of the company’s Starship space vehicle.

Other Exploration Technologies

- Lockheed Martin will partner with Kennedy to test technologies and operations for autonomous in-space plant growth systems. Integrating robotics with plant systems could help NASA harvest plants on future platforms in deep space.

NASA says the Announcement of Collaboration Opportunity helps reduce the development cost of technologies and accelerate the infusion of emerging commercial capabilities into space missions. As the agency embarks on its next era of exploration, the agency’s Space Technology Mission Directorate is focused on advancing technologies and testing new capabilities for use at the Moon that also will be critical for crewed missions to Mars.

Related Content

Composite resins price change report

CW’s running summary of resin price change announcements from major material suppliers that serve the composites manufacturing industry.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreVIDEO: One-Piece, OOA Infusion for Aerospace Composites

Tier-1 aerostructures manufacturer Spirit AeroSystems developed an out-of-autoclave (OOA), one-shot resin infusion process to reduce weight, labor and fasteners for a multi-spar aircraft torque box.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreRead Next

35th Space Symposium puts emphasis on collaboration, U.S. leadership in space

High-profile speakers at the 35th Space Symposium emphasized the need to increase collaboration with commercial entities and foreign partners to maintain U.S. dominance in space.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More