NASA awards Lockheed Martin long-term Orion production contract

The contract is an indefinite-delivery/indefinite-quantity contract that includes a commitment to order a minimum of six and a maximum of 12 Orion spacecraft over the next ten years.

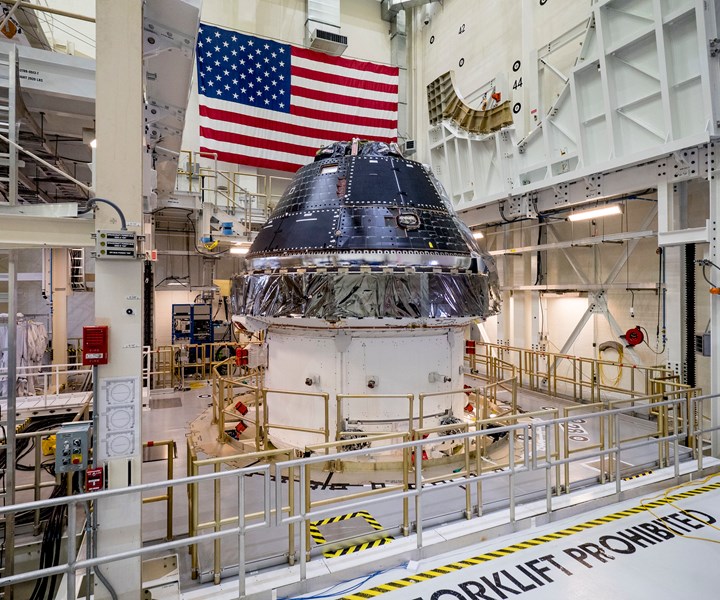

NASA completed building and outfitting the Orion crew capsule for the first Artemis lunar mission in June 2019. The spacecraft is being prepared for its uncrewed test flight atop NASA’s Space Launch System (SLS) rocket. Artemis 1 is the first test flight of the SLS and Orion spacecraft as an integrated system and will send Orion thousands of miles beyond the Moon and back to Earth. Source | NASA

On Sept. 23, NASA announced that it has awarded its Orion Production and Operations Contract (OPOC) to Lockheed Martin (Littleton, Colo., U.S.), setting in motion the Orion spacecraft production line to support as many as 12 Artemis missions to the moon and beyond. Spacecraft production for the Orion program, managed at NASA’s Johnson Space Center in Houston, Texas, will focus on reusability and building a sustainable presence on the lunar surface.

OPOC is an indefinite-delivery/indefinite-quantity contract that includes a commitment to order a minimum of six and a maximum of 12 Orion spacecraft, with an ordering period through Sept. 30, 2030. Production and operations of the spacecraft for six to 12 missions will establish a core set of capabilities, stabilize the production process and demonstrate reusability of spacecraft components.

“This contract secures Orion production through the next decade, demonstrating NASA’s commitment to establishing a sustainable presence at the moon to bring back new knowledge and prepare for sending astronauts to Mars,” says Jim Bridenstine, NASA administrator.

With this award, NASA is ordering three Orion spacecraft for Artemis missions III through V for $2.7 billion. The agency plans to order three additional Orion capsules in fiscal year 2022 for Artemis missions VI through VIII, at a total of $1.9 billion. Ordering the spacecraft in groups of three allows NASA to benefit from efficiencies that become available in the supply chain over time, optimizing production and lowering costs, the organization says.

NASA says its long-term plan is to reuse the recovered crew modules at least once. The first phase of reusability will start with Artemis II. Interior components of the spacecraft, such as flight computers and other high value electronics, as well as crew seats and switch panels, will be re-flown on Artemis V. The Artemis III crew module will be re-flown on Artemis VI.

The first six spacecraft will be acquired by cost-plus-incentive-fee ordering. Because the cost of a complex, high-tech system generally decreases over time as the design stabilizes and production processes mature, NASA will negotiate firm-fixed-price orders for future missions to take advantage of the anticipated spacecraft production cost decreases. Furthermore, the cost incentives on the cost-plus-incentive-fee orders are designed to motivate favorable cost performance during early OPOC production and drive substantially lower prices for any subsequent firm-fixed-price orders issued under this contract.

Work under this contract also will support production of NASA’s lunar-orbiting Gateway and evolving mission requirements. Production of certain spacecraft components already designed and qualified for Orion will be provided for Gateway use, eliminating the need for the Gateway Program to develop and qualify similar components.

“No other spacecraft in the world can keep humans alive hundreds of thousands of miles from Earth for weeks at a time with the safety features, crew accommodations, technical innovations, and reliability that Orion provides,” says Mark Kirasich, Orion program manager at Johnson Space Center. “With the design and development phase of Orion largely behind us, this new contract will enable us to increase efficiencies, reuse the spacecraft, and bring down the cost of reliably transporting people between earth and the Gateway.”

Related Content

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MorePlant tour: Middle River Aerostructure Systems, Baltimore, Md., U.S.

The historic Martin Aircraft factory is advancing digitized automation for more sustainable production of composite aerostructures.

Read MoreWelding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

Read MoreRead Next

NASA announces U.S. industry partners for Moon, Mars programs

The partnerships will advance the commercial space sector and help bring new capabilities to market that could benefit future NASA missions.

Read MoreLockheed Martin completes Orion spacecraft capsule

The crew module capsule has been assembled onto the Orion service module for further testing before the Artemis 1 uncrewed mission to the moon.

Read MoreOrion spacecraft completes launch abort tests

The successful test of the composites-intensive abort system moves NASA’s Orion crew capsule a step further toward travel to the Moon and beyond.

Read More

.jpg;width=70;height=70;mode=crop)