Orion spacecraft completes launch abort tests

The successful test of the composites-intensive abort system moves NASA’s Orion crew capsule a step further toward travel to the Moon and beyond.

Source | NASA

NASA successfully tested the Orion spacecraft’s launch abort system on July 2, 2019. The test is a milestone in the agency’s preparation for Artemis missions to the Moon and Mars.

During the approximately three-minute test, called Ascent Abort-2, a test version of the Orion crew module (read more on the composite heat shield in “Heatshield for Exreme Entry Environment Technology (HEEET): A broader mission”) launched from Space Launch Complex 46 at Cape Canaveral Air Force Station in Florida on a modified Peacekeeper missile procured through the U.S. Air Force and built by Northrop Grumman (Falls Church, Va., U.S.).

The Orion test spacecraft reportedly traveled to an altitude of about six miles, at which point it experienced high-stress aerodynamic conditions expected during ascent. The abort sequence triggered and, within milliseconds, the abort motor fired to pull the crew module away from the rocket. Its attitude control motor flipped the capsule end-over-end to properly orient it, and then the jettison motor fired, releasing the crew module for splashdown in the Atlantic Ocean.

Analysis of data collected from 12 data recorders that were ejected during the test capsule’s descent will provide insight into the abort system’s performance.

“We're building the most powerful rocket in the world to send astronauts to the Moon in the Orion spacecraft for Artemis missions,” says Bill Hill, deputy associate administrator for exploration systems development at NASA headquarters in Washington, D.C. “With this exploration system designed to safely carry humans farther into space than ever before, we'll also have an equally powerful launch abort system that will pull the crew away if there is a problem with the rocket during the early portion of ascent.”

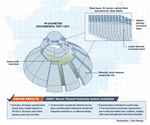

The tower-like abort structure consists of two parts: the fairing assembly, which is a shell composed of a lightweight composite material that protects the capsule from the heat, air flow and acoustics of the launch, ascent and abort environments; and the launch abort tower, which includes the abort motor, attitude control motor and jettison motor. The system is built specifically for deep space missions and to ride on NASA’s powerful Space Launch System (SLS) rocket.

“Launching into space is one of the most difficult and dangerous parts of going to the Moon,” says Mark Kirasich, Orion program manager at Johnson Space Center in Houston, Texas. “This test mimicked some of the most challenging conditions Orion will ever face should an emergency develop during the ascent phase of flight. Today, the team demonstrated our abort capabilities under these demanding conditions and put us one huge step closer to the first Artemis flight carrying people to the Moon.”

Related Content

-

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

-

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

.jpg;width=70;height=70;mode=crop)