New Digimat 2019.1 release enables smarter fiber-reinforced composite design values, allowables and crash modeling

Upgrades include high fiber content virtual test with 10-100 times faster analyses and progressive damage analysis using the Camanho method.

Source | Hexagon

e-Xstream engineering (Newport Beach, Calif., U.S.), a market leader in materials simulation software and engineering services and part of Hexagon (North Kingstown, R.I., U.S.), announces advanced new capabilities to derive more accurate design values for fiber-reinforced composites, to model structural crash of sheet molding compound (SMC) and to understand the safety limits of lightweighting using the Camanho method.

Digimat 2019.1 provides mechanical engineers with a new approach to determine allowables in safety-critical industries, complementing physical test campaigns to determine material variability and performance through simulation and establish greater confidence in “virtual coupon” tests.

Camanho model

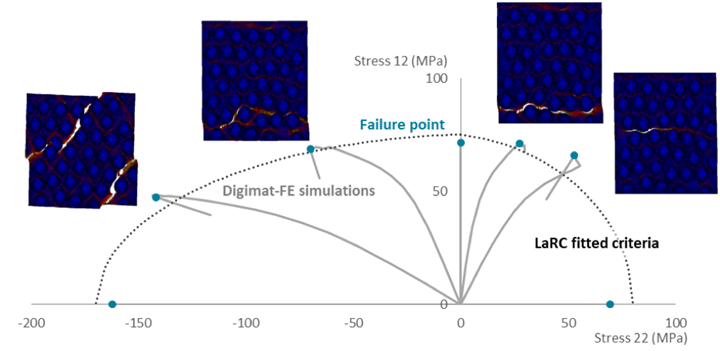

Digimat now implements Prof. Camanho’s Progressive Damage Analysis model, making it possible for users to comprehensively model how material choices affect the failure of continuous fiber-reinforced plastic (CFRP) from coupon to manufactured panel and improve the accuracy of composite allowables. Complementary model developments in this software release enable materials professionals to better estimate the effect of defects such as porosity, out of plane waviness and delamination to compute more accurate margin factors and appropriate tolerances.

Philippe Hébert, product manager at e-Xstream engineering, comments, “Allowables have long been rooted in the safe limits of metals, but as sustainability drives lightweighting, we need more accurate simulation of composite failure in manufactured structures. Building on Professor Camanho’s extensive research, we can now offer manufacturers powerful tools that complement their physical test campaigns to save cost and optimize material use earlier in the design process.”

Source | Hexagon

High fiber content composites

Material modeling is also improved for high fiber content CFRP. Microstructure analyses now replace random fiber placement with realistic fiber positions based on the Melro statistical model to enable direct engineering of the material.

Fast Fourier Transform solver

Meshing complex geometries to the required density and scale for finite element analysis is rarely feasible. A new Fast Fourier Transform (FFT) solver makes it possible to analyze advanced composite materials microstructures, and computes 10-100 times faster. By eliminating time-consuming meshing and accelerating computation, users can screen more materials and investigate the performance of a material across more dimensions.

Short fiber-reinforced plastic

Digimat 2019.1 also advances manufacturing process simulation. Design engineers can now accurately predict fatigue lifetime to design more optimal parts using short fiber-reinforced plastic (SFRP). A new model resulting from continued collaboration with DSM Engineering Plastics enhances fatigue modeling to account for local plasticity in SFRP under constant load amplitude.

Modeling SMC in crash

An industry-first approach to modeling structural crash applications also now enables design engineers to better understand how common manufacturing issues affect SMC, for example enabling lightweighting at point of design for automotive applications. Built-in modeling accounts for varying anisotropy, damage propagation and weld line weakness.

Related Content

-

Bio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

-

Composites end markets: Electronics (2024)

Increasingly, prototype and production-ready smart devices featuring thermoplastic composite cases and other components provide lightweight, optimized sustainable alternatives to metal.

-

Plant tour: Middle River Aerostructure Systems, Baltimore, Md., U.S.

The historic Martin Aircraft factory is advancing digitized automation for more sustainable production of composite aerostructures.