Novel OCSiAl graphene nanotube concentrate enables conductive thermoplastics

Validated Tuball Matrix 808 provides thermoplastics with optimized electrical conductivity but retains mechanical properties and has minimal impact on a high MFI.

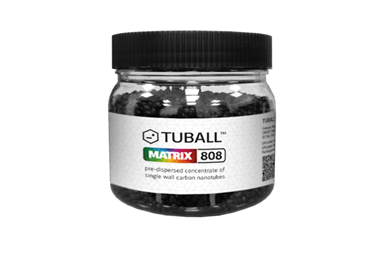

A novel product, Tuball Matrix 808 graphene nanotube concentrate, launched by OCSiAl (Luxembourg and Columbus, Ohio, U.S.), is said to enable high-quality conductive thermoplastics, demonstrating permanent, stable conductivity without any variations at the surface and with no adverse effects on mechanical or rheological properties. This is in direct contrast to conventional conductive agents, OCSiAl says, which often have a negative impact on thermoplastic mechanical properties, thus increasing the number of out-of-spec parts.

The concentrate was specifically designed for fiber-filled PA, PPS and PBT, and neat ABS, TPU and PC compounds, and can be used with injection molding, extrusion and compression production methods. The formulation also makes it possible to incorporate nanotubes in just one step — direct compounding — resulting in cost efficiency and simplified handling of nanotubes by any manufacturer.

“In contrast to conventional additives, graphene nanotubes used at an ultralow working dosage bring additional value by preserving good impact strength and a high MFI [melt flow index] level that makes it possible to produce complex injection-molded parts,” Vladimir Kravchenko, development and support leader for thermosets, thermoplastics, construction materials, OCSiAl Group, says. “This is particularly hard to achieve in fiberglass-filled compounds using multiwall carbon nanotubes or carbon black.”

Tuball Matrix 808 shows promise for a variety of industry applications, including this signal lamp for miners.

Tuball Matrix 808 has passed a stage of validation by European polymer compound producers. The manufacturers tested various formulations of polymers that showed conductivity of 103-109 ohm at concentrations of graphene nanotubes of 0.1-0.5 wt%. For example, PA6 compound with 30 wt% glass fiber enhanced with 0.15 wt% graphene nanotubes demonstrates permanent, stable volume resistivity of 104 Ω·cm and surface resistivity of 106 ohm/sq after injection molding. According to OCSiAl, one of the applications of such nanotube-enhanced PA parts, e-painting of automotive car parts, is reported to be more cost efficient.

Moreover, a sustainable method of production without carbon dust, with less required loading of conductive agent and preserved durability of the plastics, like OCSiAl’s Tuball Matrix 808 concentrate can be attractive to compounders and thermoplastic product manufacturers. Application potential can increase for use in automotive, various construction parts and ESD products for ATEX areas such as in the oil and gas, chemical and electronics industries.

OCSiAl’s graphene nanotube solutions have also advanced applications in electric vehicle (EV) battery packs and GFRP pipes.

Related Content

-

JEC World 2024 highlights: Thermoplastic composites, CMC and novel processes

CW senior technical editor Ginger Gardiner discusses some of the developments and demonstrators shown at the industry’s largest composites exhibition and conference.

-

Optimizing a thermoplastic composite helicopter door hinge

9T Labs used Additive Fusion Technology to iterate CFRTP designs, fully exploit continuous fiber printing and outperform stainless steel and black metal designs in failure load and weight.

-

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.