OptiBlade project increases rotor wind blade production efficiency

Successful completion of project led by Fraunhofer IFAM sees the development of stretch-formable PeelPlas film for release agent-free demolding of FRP components.

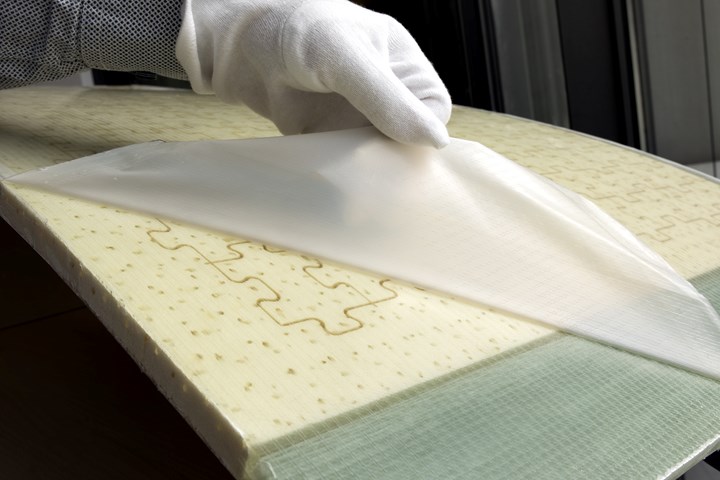

Pre-treatment-free coatable demonstrator of a rotor blade shell segment protected by the PeelPlas release film. Photo Credit, all images: Fraunhofer IFAM

Within the joint project OptiBlade, researchers at the Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM (Fraunhofer IFAM, Germany), in collaboration with Olin Blue Cube Germany and Infiana Germany, have pioneered a release agent-free process and material systems that have the potential to transform rotor blade production for wind turbines. This development is poised to propel the expansion of wind turbines in alignment with the Energy Concept 2050.

As part of this project, Fraunhofer IFAM initiated the operation of a state-of-the-art low-pressure plasma plant tailored for web material and devised plasma processes capable of applying an ultrathin plasma polymeric release layer to polymer film half-tubes up to 2.4 meters wide. The resulting flexible and stretch-formable PeelPlas release film, an evolution of the Fraunhofer IFAM FlexPlas release film, expands to a width of up to 4.8 meters when unfolded. Moreover, this release film can be seamlessly welded for even wider molds used in fiber-reinforced plastic (FRP) rotor blade production without any complications.

Furthermore, through a specialized process, a 4.2-meter PeelPlas release film half-tube was applied onto an 18-meter segment mold at Fraunhofer IWES, in cooperation with Olin Blue Cube Germany, creating a 40-meter-long FRP rotor blade demonstrator. The plasma-coated PeelPlas release film facilitated transfer-free demolding of the large FRP component, eliminating the need for traditional release agents. Subsequently, the epoxy resin matrix of the component was coated with a repair coating for rotor blades without additional pre-treatment, showcasing optimal adhesion even after exposure to a condensation water test for 1,000 hours.

The flexible vacuum stretch-formed PeelPlas release film fits like a second skin into the 18-meter-long rotor blade segment mold and enables release agent-free demolding of the large FRP component after production.

The Plasma Technology and Surfaces experts and Automation and Production Technology experts at Fraunhofer IFAM developed the plasma-coated flexible PeelPlas release film based on a thermoplastic elastomer. This release film, tailored to specific industry and customer requirements, substitutes conventional release agents, ensuring carryover-free and reliable component demolding, thereby ensuring consistently high component quality for contamination-free, large FRP components.

The processes developed by Fraunhofer IFAM under OptiBlade using the PeelPlas release film are reported to significantly enhance value addition throughout the process chain. Notably, these innovations optimize rotor blade surface quality, eliminate labor- and time-intensive manual tasks in tool molds and reduce mold loading time, thereby extending mold service life.

The successful culmination of the OptiBlade project’s first phase has spurred plans for a new plasma-coated multilayer film under the “Sustainable and efficient rotor blade production with emission-reduced processes for the formation of surfaces” (NEOFOIL) cooperation project as part of the 7th Energy Research Program of the German Federal Ministry for Economic Affairs and Climate Action (BMWK). This new film aims to serve as a semi-permanent release film affixed to molds, enabling multiple demoldings of FRP components, thereby reducing waste and optimizing work requirements and mold occupation time.

Moreover, the knowledge and technologies derived from OptiBlade are poised for transfer to diverse industries such as aircraft, spacecraft, rail vehicle, commercial vehicle, automotive, shipbuilding and sports equipment manufacturing, promising increased efficiency in their production processes.

Following a duration of more than four years, the first phase of the sub-project “Release film technology for optimized rotor blade production” under the OptiBlade joint project has concluded, with gratitude extended by Fraunhofer IFAM to the project partners and funders for their invaluable support.

Related Content

Rocket Lab begins installation of large AFP machine for rocket production

The 99-ton AFP machine, custom-designed and built by Electroimpact, is claimed to be the largest of its kind, expecting to save around 150,000 manufacturing hours in the Neutron rocket’s production process.

Read MoreDaher CARAC TP project advances thermoplastic composites certification approach

New tests, analysis enable databases, models, design guidelines and methodologies, combining materials science with production processes to predict and optimize part performance at temperatures above Tg (≈150-180°C) for wing and engine structures.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreBioabsorbable and degradable glass fibers, compostable composite parts

ABM Composite offers sustainable options and up to a 60% reduction in carbon footprint for glass fiber-reinforced composites.

Read MoreRead Next

Proper application of semi-permanent mold release systems

Performing regular maintenance of the layup tool for successful sealing and release is required to reduce the risk of part adherence.

Read MoreFraunhofer IFAM advances automation, robotics development for large composite structures

New developments in automated or semi-automated manufacturing solutions through MFFD, CoMMaNds 2, FastFlexMont 2, Tempo and UniFix projects to achieve sustainable, efficient composite part production.

Read MoreHaliade-X offshore wind turbine becomes operational at Dogger Bank

The first of GE Vernova’s next-gen 13-MW+ wind turbine has begun producing power at sea following 3 years of testing, supporting both U.K. and U.S. wind farm projects.

Read More