Orbital Composites, ORNL collaborate to advance robotic polymer and composite AM

The research will focus on the development of a commercially-ready system capable of robotic overprinting on pre-manufactured non-planar surfaces, with multi-material polymers and continuous fiber.

Share

Read Next

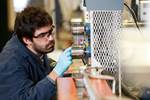

Orbital's ORB robotic 3D printing platform being installed at Department of Energy’s Manufacturing Demonstration Facility at ORNL. Photo Credit: Orbital Composites, ORNL

It was announced on Sept. 22 that Orbital Composites (San Jose, Calif., U.S.), a start-up company building disruptive industrial-scale digital manufacturing platforms, and Oak Ridge National Laboratory (ORNL; Knoxville, Tenn., U.S.) signed a cooperative research and development agreement to develop out-of-plane, robotic polymer and composite additive manufacturing (AM) technology. The agreement is said to build upon Orbital Composites’ novel ORB platform for robotic neat polymer and continuous-fiber AM platform and ORNL’s expertise in materials science and scaling-up AM systems.

According to ORNL and Orbital Composites, research will focus on the development of a commercially-ready system capable of robotic overprinting on pre-manufactured non-planar surfaces, with multi-material polymers and continuous fiber. It is said this will enable the seamless integration of polymer and composite AM with other processes as well as the transition to industry 4.0 manufacturing strategies. According to both partners, significant energy and materials savings will be realized in this manufacturing technology due to the efficient use of specific manufacturing processes and materials.

“This collaboration will result in technology that can serve a number of industries by incorporating additive manufacturing with complex shapes that weren’t possible to produce through traditional manufacturing methods,” says ORNL’s Vlastimil Kunc, lead researcher on the project. “Integration of multiple manufacturing processes and fusion of digital and physical space will also be a significant step toward industry 4.0 implementation.”

Large-scale, fine-precision, high-speed AM has recently become a reality, says the partners. Orbital’s AM systems, for example, have demonstrated robotic overprinting on a curved surface, and continuous fiber printing with many different matrices.

“The next small step for 3D printing is to combine the innovations of both systems, resulting in the next giant leap in aerospace and automotive manufacturing,” says Cole Nielsen, Orbital’s founder and CTO. “The optimized placement of single fiber tows and low density meshes onto curved surfaces will enable the cost-effective use of AM for serial production.”

Related Content

-

Demonstrating functionalized, cost-effective composites using additive extrusion

Hybrid thermoset/thermoplastic composite part with 3D-printed functionalization demonstrates technology possibilities and EmpowerAX open platform offering expertise from members throughout the process chain.

-

Hybrid process marries continuous, discontinuous composites design

9T Labs and Purdue applied Additive Fusion Technology to engineer a performance- and cost-competitive aircraft bin pin bracket made from compression-molded continuous and discontinuous CFRTP.

-

Optimizing a thermoplastic composite helicopter door hinge

9T Labs used Additive Fusion Technology to iterate CFRTP designs, fully exploit continuous fiber printing and outperform stainless steel and black metal designs in failure load and weight.