Plastic Omnium confirms its position in CFRP hydrogen storage tanks

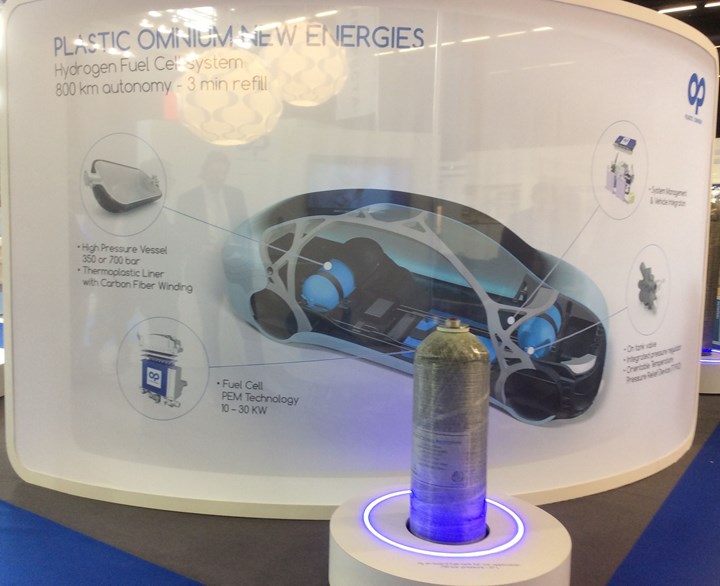

Contract for 350-bar bus tanks and certification for 700-bar passenger car tanks recognize developed technology and strategy for growing global hydrogen/fuel cell ecosystem.

SOURCE | Plastic Omnium

Plastic Omnium (Levallois, France) has recently won a significant order from a German manufacturer for the development of 350-bar hydrogen tanks. The contract signed for bus equipment is the largest project in Europe at this time for this type of vehicle.

In parallel to this success, Plastic Omnium has just obtained its first certification for a 700-bar hydrogen storage tank designed to equip passenger cars. The R134 certification is an international standard comprising the strictest specifications for the regulation of high-pressure hydrogen tanks. Other certifications are underway for 350-bar hydrogen tanks and for CNG (compressed natural gas) tanks.

Plastic Omnium reports that this contract and first certification demonstrate the recognition of its technological know-how, developed in the field of high-pressure composite plastic tanks over the last four years. In 2016, the company formed PO-Celltech (Caesarea, Israel) with Elbit Systems, drawing on its decades of leadership in advanced electronics to develop novel technology for low-cost, mass-produced fuel cells and supercapacitors for automotive. Then in 2017, Plastic Omnium acquired Optimum CPV (Zonhoven, Belgium), a specialist in filament wound composite high-pressure hydrogen storage tanks, and Swiss Hydrogen (Fribourg, Switzerland) which produces solutions for the management and control of energy in fuel cell systems.

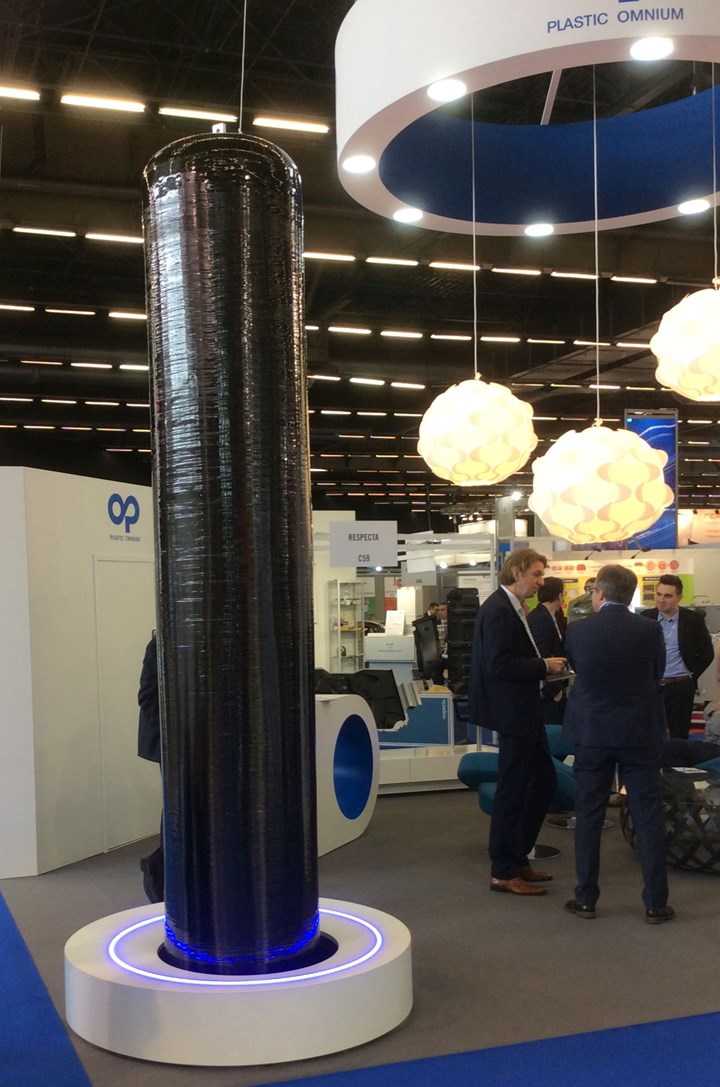

Plastic Omnium displayed multiple carbon fiber filament wound hydrogen storage tanks at JEC 2018. SOURCE | CW

Plastic Omnium’s hydrogen strategy has recently been reinforced by the opening of two R&D centers, Δ-Deltatech in Brussels and ω-Omegatech in Wuhan, China, where a pilot carbon filament winding line has recently been inaugurated. In 2020, Plastic Omnium will also install a dedicated hydrogen tank production line at its Herentals, Belgium fuel tank plant. In addition, its investment in AP Ventures, a venture capital fund based in London and dedicated solely to hydrogen, reportedly provides Plastic Omnium with opportunities and interesting choices for the future.

As a global leader in fuel and emissions control systems, Plastic Omnium is thus confirming its position as a major player in the clean mobility market and the emerging landscape for carbon fiber composite pressure vessels.

Related Content

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

-

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

-

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.