Rize presents Rizium glass fiber material for 3D printing

Based on an olefin matrix, Rizium glass fiber composites are suitable for full color parts, is GREENGUARD certified for low emissions and supports complex geometries.

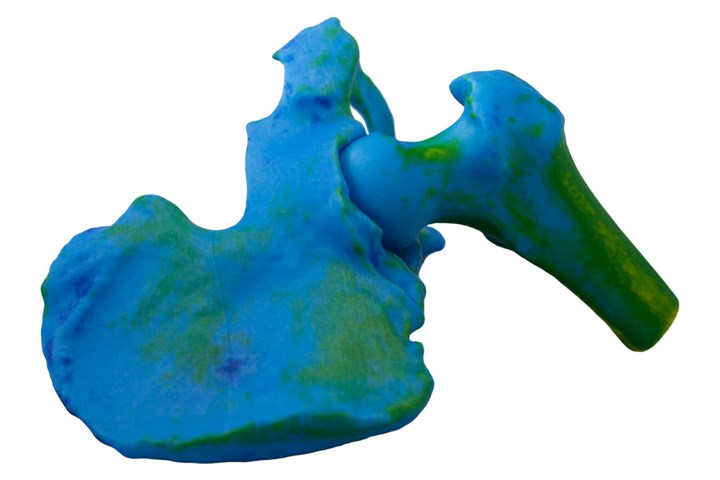

Color models depicting Rize’s Rizium GF. Source | Rize Inc.

Rize Inc. (Concord, Mass., U.S.) a next-generation additive manufacturing company announced on August 13 the immediate availability of its Rizium glass fiber (GF) composite 3D printing material, which is said to retain high-dimensional stability to support parts with complex geometries that often warp, and high stiffness for large part strength requirements. Rize says that, as the only composite 3D printing materials suitable for full-color parts, the product is open to full color prototyping, as well as new applications in education, industrial and life science categories where life-like color in durable parts can transform user experience. Further, Rizium is said to provide the flexibility to expand 3D printing uses, safely and sustainably.

Available on Rize’s entire suite of 3D printers including those from Rizium Alliance industry partners, Rizium GF is said to be based on the company’s unique cyclic olefin-based matrix, which does not release emissions at extrusion temperatures, has very low moisture absorption and retains high chemical resistance. Tested and proven for durability and strength, Rize says that the product leverages its augmented polymer deposition (APD) digital material technology that enables the polymer material to combine with functional inks to create new material properties. Rizium GF is also said to be stable over large build volumes.

Ronnie Sherrer, application engineer at Azoth (Ann Arbor, Mich., U.S.) points out that its customers appreciate the product’s ability to deliver print reliability, quality and strength in 3D-printed parts.

Further, Rizium GF also has obtained GREENGUARD Certification on the Xrize full-color composite 3D printing platform, confirming it is safe to be used in offices, schools, hospitals and any enclosed spaces. It is noted that this is Rize’s fourth innovation to obtain this certification, including its Xrize full-composite 3D printer, its Rizium ST 3D printing filament material, Rizium inks and Rize One monochrome printer.

Rize is a World Economic Forum (WEF) 2020 Technology Pioneer.

Related Content

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

-

Plant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

-

Recycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.