James Webb telescope reaches mirror alignment milestone, optics working successfully

Following the completion of critical mirror alignment steps, NASA’s James Webb Space Telescope has reported optical performance that could exceed original expectations.

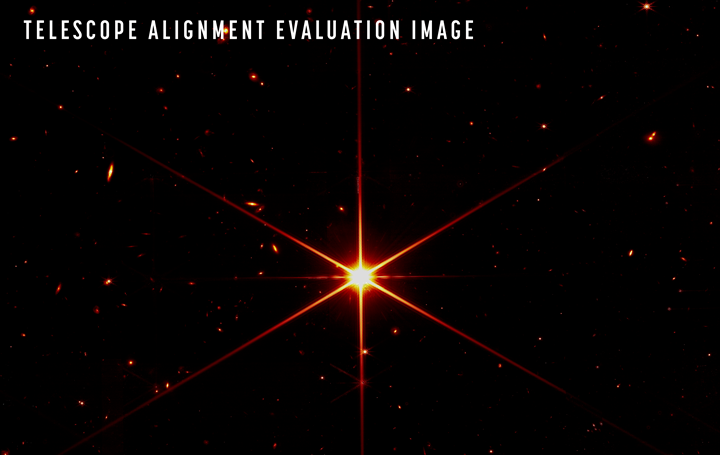

While the purpose of this image was to focus on the bright star at the center for alignment evaluation, Webb’s optics and NIRCam are so sensitive that the galaxies and stars seen in the background show up. At this stage of Webb’s mirror alignment, known as “fine phasing,” each of the primary mirror segments have been adjusted to produce one unified image of the same star using only the NIRCam instrument. This image of the star, which is called 2MASS J17554042+6551277, uses a red filter to optimize visual contrast. Photo Credit: NASA/STScI

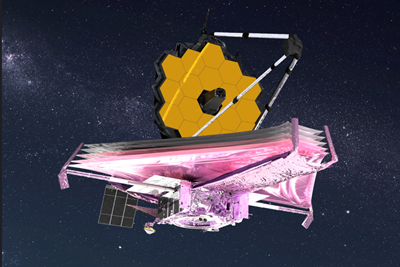

Following the completion of critical mirror alignment steps, NASA’s (Washington, D.C., U.S.) James Webb Space Telescope (JWST) team expects that Webb’s optical performance will be able to meet or exceed the science goals the observatory was built to achieve.

On March 11, the Webb team completed the stage of alignment known as “fine phasing.” At this key stage in the commissioning of Webb’s Optical Telescope Element, every optical parameter that has been checked and tested is performing at, or above, expectations. The team also found no critical issues and no measurable contamination or blockages to Webb’s optical path. The observatory is able to successfully gather light from distant objects and deliver it to its instruments without issue.

Although there are months to go before Webb ultimately delivers its new view of the cosmos, achieving this milestone means the team is confident that Webb’s first-of-its-kind optical system is working as well as possible.

“More than 20 years ago, the Webb team set out to build the most powerful telescope that anyone has ever put in space and came up with an audacious optical design to meet demanding science goals,” says Thomas Zurbuchen, associate administrator for NASA’s Science Mission Directorate in Washington. “Today we can say that design is going to deliver.”

While some of the largest ground-based telescopes on Earth use segmented primary mirrors, Webb is said to be the first telescope in space to use such a design. The 21-foot, 4-inch (6.5-meter) primary mirror is made up of 18 hexagonal, beryllium mirror segments. It had to be folded up for launch and then unfolded in space before each mirror was adjusted — to within nanometers — to form a single mirror surface.

“In addition to enabling the science that Webb will achieve, the teams that designed, built, tested, launched and now operate this observatory have pioneered a new way to build space telescopes,” adds Lee Feinberg, Webb optical telescope element manager at NASA’s Goddard Space Flight Center in Greenbelt, Maryland.

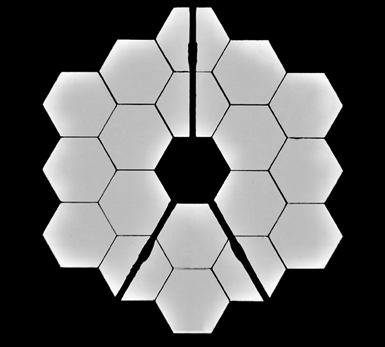

This new “selfie” was created using a specialized pupil imaging lens inside of the NIRCam instrument that was designed to take images of the primary mirror segments instead of images of the sky. This configuration is not used during scientific operations and is used strictly for engineering and alignment purposes. In this image, all of Webb’s 18 primary mirror segments are shown collecting light from the same star in unison. Photo Credit: NASA/STScI

With the fine phasing stage of the telescope’s alignment complete, the team has now fully aligned Webb’s primary imager, the Near-Infrared Camera, to the observatory’s mirrors. “We have fully aligned and focused the telescope on a star [shown above], and the performance is beating specifications. We are excited about what this means for science,” says Ritva Keski-Kuha, deputy optical telescope element manager for Webb at NASA Goddard. “We now know we have built the right telescope.”

Over the next six weeks, the team will proceed through the remaining alignment steps before final science instrument preparations. The team will further align the telescope to include the Near-Infrared Spectrograph, Mid-Infrared Instrument and Near InfraRed Imager and Slitless Spectrograph. In this phase of the process, an algorithm will evaluate the performance of each instrument and then calculate the final corrections needed to achieve a well-aligned telescope across all science instruments. Following this, Webb’s final alignment step will begin, and the team will adjust any small, residual positioning errors in the mirror segments.

The team is on track to conclude all aspects of Optical Telescope Element alignment by early May 2022, if not sooner, before moving on to approximately two months of science instrument preparations. Webb’s first full-resolution imagery and science data will be released in the summer, close to July.

Related Content

Plant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreComposites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

Read MoreASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MoreRead Next

James Webb Space Telescope reaches major milestone as primary mirror unfolds

Full deployment of the 21-foot, gold-coated primary mirror completes the final stage of all major spacecraft deployments in preparation for science operations.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More