Strata automates Airbus A350 inboard flap production line

With two MTorres automated tape laying (ATL) machines, the UAE-based aerostructures manufacturer plans to reduce processing times for aircraft components.

Share

Source | Strata Manufacturing

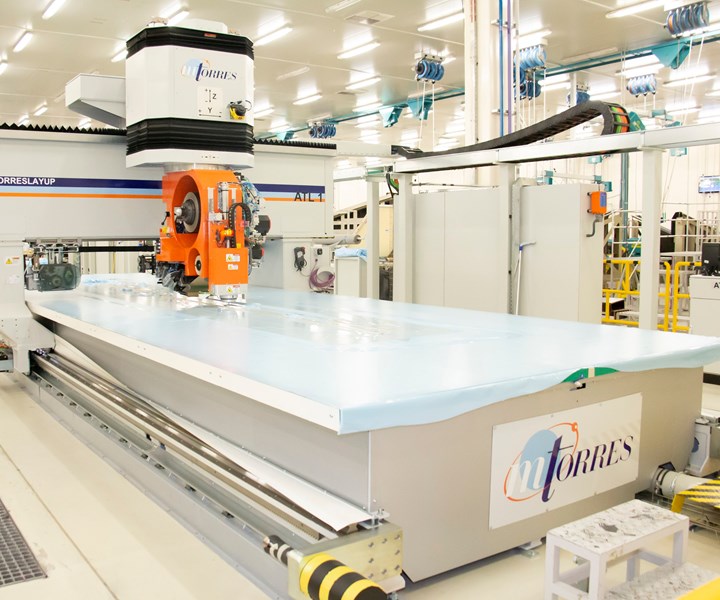

Composite aerostructures manufacturer Strata Manufacturing (Strata, Al Ain, United Arab Emirates), which manufacturers inboard flap components for the Airbus A350-900, reported on March 16 that it is deploying two latest-generation MTorres (Navarra, Spain) automated tape laying machines (ATL) for its manufacturing capabilities.

Specifically, Strata says it has gained First Part Qualification and First Article Inspection design and quality verifications for the use of the computer-controlled robotic ATL machines that will automate Strata’s production of the inboard flap components.

The two ATL machines lay unidirectional (UD) carbon fiber prepreg materials onto a flat bed, which is then transferred to a mold tool for further processing. The machines have a work envelope of 2.5 meters by 10 meters, automating large composite layup without the need for a separate ultrasonic cutting machine. Through this technology, Strata says it hopes to drastically reduce processing times in comparison to standard hand layup processes.

“Through the quick adoption of cutting-edge technologies and solutions such as ATL, Strata will further advance its position in the global aerospace industry, facilitate our evolution to manufacture more complex aircraft parts…,” says Ismail Ali Abdulla, CEO of Strata.

Five of Strata’s employees traveled to Spain for a five-day training course on the operation of the ATL machine. The training course covered a complete overview of the system, such as machine operation and maintenance.

“As we aim to continue delivering high-quality products to our customers, we consider the integration of machines and robotics vital in creating an efficient manufacturing system,” Abdulla adds.

With the support of its industry partners, Strata says it is also incubating technologies such as additive manufacturing, robotic assembly of aircraft structures, advanced inspection techniques through thermography, and optimization of processing and machining of composite parts.

Related Content

-

The next evolution in AFP

Automated fiber placement develops into more compact, flexible, modular and digitized systems with multi-material and process capabilities.

-

Jeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

-

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

.jpg;width=70;height=70;mode=crop)