Strength of composite whale tail sculpture saves runaway train car

A 19-year-old, glass fiber-reinforced composite urban sculpture designed by Dutch engineering firm Solico was able to safely bear the weight of an off-track rail vehicle.

Photo Credit: Solico

Early in the morning of Nov. 2 in Rotterdam suburb Spijkenisse, Netherlands, a runaway subway car is reported to have burst through the rail platform’s buffer stop while approaching the end of the line, coming to rest on a giant, glass fiber composite sculpture shaped like a whale’s tail. The driver, who was the only person on the train, is reported to be uninjured in the accident. The sculpture, one of two “Whale Tails” urban sculptures at the end of the train line, kept the car from plummeting onto a bike path 12 meters (39 feet) below.

Catching runaway trains, of course, was not the original design intent of the sculptures, which were built and installed 19 years ago by fabricator Maropol. Dutch composites engineering specialist Solico (Oosterhout, Netherlands) reports that it was commissioned to provide structural engineering for the tail sculptures in 2001 by the Municipality of Rotterdam.

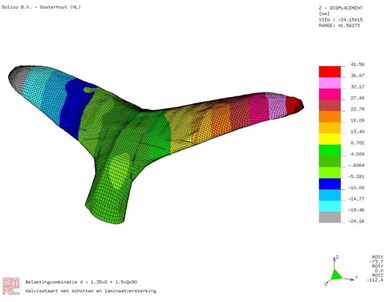

The tails are 12 and 14 meters tall, respectively (about 39 and 46 feet), with a footprint each of 3.8 meters (13 feet) wide at the base and 8.2 meters (27 feet) wide across the tail. The whale tails consist of two parts, which are referred to as the “body” and the “tail.” The body has a steel lattice interior structure, clad with 6 millimeters of glass fiber-reinforced polyester. Solico adds that the tail structure, on which the train car landed, does not include a steel support, meaning the load was taken by the composite material alone.

The composite materials for the sculptures were originally chosen both to enable the complex shapes of the tails but to also reach the required strength and stiffness to withstand the wind conditions experienced in the area. According to Solico, Rotterdam’s location along the coast and within an urban area with many buildings causes particular wind vortexes and high wind loads. Nearby architectural projects in that area had faced issues due to wind vibrations, so care was taken to ensure these sculptures avoided those issues. The sculptures were analyzed via finite element analysis (FEA), and Solico’s founder Hans Muller and Solico engineer Peter Globevnik tested the sculptures in a wind tunnel to make sure they could withstand the appropriate vortexes, lift and air circulation for the area.

According to Solico, Muller and Eric van Uden, another engineer who worked on the original sculpture’s engineering, were both shocked at the news — Van Uden reportedly said the images “looked like a scene from a movie” — but they are unsurprised by the sculptures’ strength. Solico believes that the structure was able to hold the train because of its original composites engineering. “It was never meant to support the train, but we understand that it could do the job,” says Rebecca Anderson, marketing manager at Solico.

Related Content

-

AMRC Training Centre introduces composites apprenticeship opportunity

With partners McLaren and Teledyne CML Composites, the Training Center will train new composites technicians in South Yorkshire to build up the future industry workforce.

-

Women in the Composites Industry brings together women for networking, educational opportunities

Aiming to support the growth of women in this industry, the WCI industry group and its partners recently held its first live training event hosted by Owens Corning.

-

NASA names university teams for aeronautics research challenges

As part of the agency’s University Leadership Initiative, three multidisciplinary teams will address topics related to growth in AAM, while a fourth examines electricity generation for future airliners.

.jpg;width=70;height=70;mode=crop)