The Gill Corp. is awarded Boeing contract extension

Initial 2014 Tier 1 contract with Boeing has been extended to include composite floor panel fabrication for the 777, 777X and 787 programs.

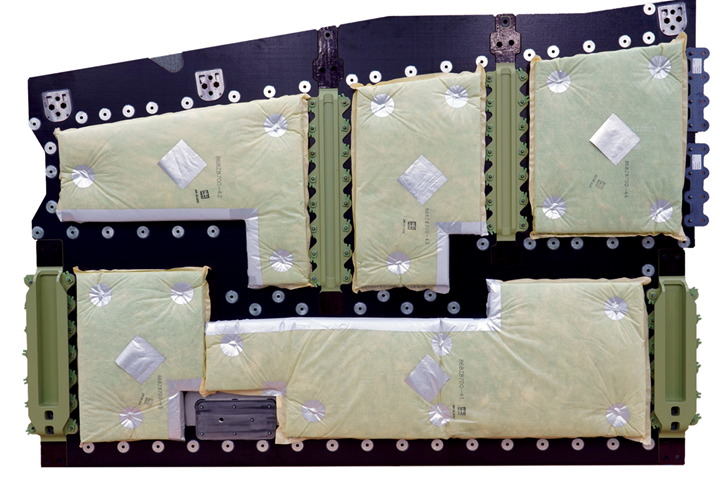

The Gill Corp. (TGC, El Monte, Calif., U.S.) has been awarded a production contract extension with Boeing (Chicago, Ill., U.S.) to supply fabricated floor panel assemblies for the Boeing 777, 777X and 787 programs.

The company provides the “drop-in ready” kitted shipsets directly to Boeing. TGC was initially awarded the Tier 1 contract for the 787 program in 2014, followed by fabrication contracts for the 777 and 777X programs, all of which used TGC’s lightweight, high-performance composite sandwich panels. TGC supplies the sandwich panel materials for the Boeing 737 and 767 programs, along with honeycomb core, machined core details, honeycomb bonded assemblies, cargo liner laminates and sandwich panels to Boeing’s global supply chain for almost every commercial and military program.

“I would like to thank our TGC staff for their efforts towards extending the contract award,” TGC’s chairman and CEO, Stephen Gill, says. “The company is looking forward to continuing its support of Boeing 777 and 777X final assembly in Everett, Washington, and 787 final assembly in North Charleston, South Carolina. This contract extension continues our partnership with Boeing into the future for years to come.”

Related Content

-

Plant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

-

Composites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

-

Welding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.