Trelleborg launches low-friction thermoplastic composite bearing

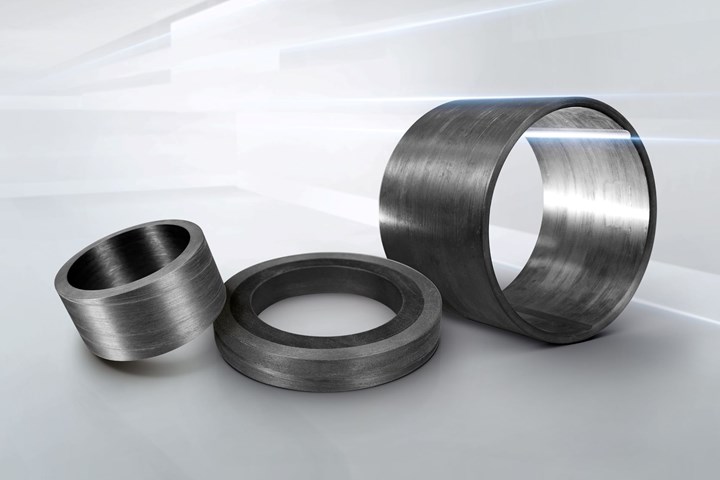

The HiMod Advanced Composite Bearing Plus is a dual-layer bearing with a low-friction PEEK liner that doubles as an impermeable sealing surface, in addition to 50% less sliding friction, increased wear performance.

Trelleborg Sealing Solutions (Trelleborg, Sweden) launches its latest lightweight thermoplastic composite bearing, the HiMod Advanced Composite Bearing Plus, an enhanced dual-layer bearing with a low-friction modified polyetheretherketone (PEEK) layer that reduces friction and increases wear performance for use in bearing, wear ring and bushing applications.

Manufactured using Trelleborg’s patented automated fiber placement (AFP) technology, a thin low-friction liner is bonded to the inner diameters and can be added to the outer diameters of the bearing to create a high-quality solution for use in a wide range of industries. According to the company, HiMod Advanced Composite Bearing Plus will not seize or gall, unlike metal bearings, to reduce the likelihood of pump damage in chemical processing applications, has a low coefficient of friction and can withstand extreme temperature ranges.

“Thermoplastic bearings offer high durability and toughness for demanding applications,” Reid Hislop, product manager at Trelleborg Sealing Solutions, says. “The addition of a low-friction layer provides up to 50% less sliding friction than with standard bearings, to increase performance and prevent damage to hardware components.”

Hislop says the bearings can operate from a low temperature of -156ºC to +274ºC/-250ºF to +525ºF and are capable of continuous service even when wet, with nearly zero water absorption. Unlike other non-metal bearings, Trelleborg’s solution reportedly doesn’t crack or swell in extreme conditions, making them reliable for a wide range of applications.

Trelleborg’s AFP technology is part of a continuous fiber thermoplastic composite manufacturing process, which uses unidirectional (UD) prepreg tapes to produce strong, lightweight composite bearings and other components. The manufacturing process uses in-situ consolidated (ISC) technology that requires no autoclave or other postprocessing to eliminate fiber wrinkling and offer what is said to be an unlimited choice of fiber angles. Components are rapidly formed by a melt-bond process, which removes the need for adhesives, fasteners or welding. ISC technology enables the bonding of different materials which can result in the creation of new, hybrid structures.

“Our low-friction PEEK liner doubles as a highly impermeable sealing surface to provide wide chemical compatibility including solvents and environmental contaminants, and unlike traditional thermoset composites, thermoplastic composites can be recycled at end of life,” Hislop adds.

Related Content

-

Jeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

-

Composites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.