Deutsche Aircraft and H2FLY join forces to explore hydrogen powered flight

First flight of Dornier 328 demonstrator with fuel cell planned for 2025 to display potential for climate-neutral regional flights.

The partnership will see the two companies convert the Dornier 328 aircraft for hydrogen flight, with the demonstrator aircraft expected to take to the skies in 2025. The program is expected to validate the potential for hydrogen to deliver climate-neutral regional air travel with up to 40 seats, while demonstrating German leadership in this important field.

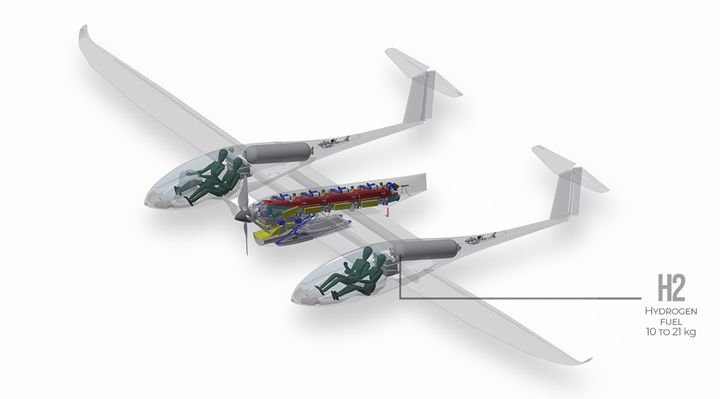

Having grown out of a partnership between the German Aerospace Center and the University of Ulm, H2FLY is said to have demonstrated innovative hydrogen fuel cell technology in aviation. The four-seater hydrogen-electric-powered HY4 has proven successfully, in multiple flight campaigns and more than 70 take-offs, the applicability of this technology in aviation. With its range of up to 750 kilometers, says H2FLY, the HY4 proves that regional markets can be developed.

A redundant compressed hydrogen gas storage system allows long flight testing and refueling in minutes. In a next step, liquid hydrogen will boost the range and allow H2FLY to assess technical feasibility. Photo credit: H2FLY

This partnership represents the next step towards making climate-neutral regional flight a reality. The teams plan to equip the demonstrator aircraft with a 1.5-megawatt hydrogen system, making it what the company contends is the most powerful hydrogen-electric-powered aircraft to date. The companies will integrate the power system into the aircraft and define the specific technical and certification requirements for fuel cell systems in EASA’s large aircraft class (CS25). The project is designed to complement the German Federal Government’s Aviation Strategy.

“Flying provides an important opportunity for humankind, but today that opportunity comes at a significant cost to our planet,” says Dr. Josef Kallo, co-founder and CEO of H2FLY. “Hydrogen fuel cell technology provides an opportunity for us to completely eliminate carbon and NOx emissions from regional flights and the technology to make that happen is closer than most people think. Over the last 16 years, we have worked hard to demonstrate our technology on smaller aircraft, completing record-breaking flights based on six powertrain generations. Today, we’re pleased to be taking that to the next level with Deutsche Aircraft as we scale our efforts up to regional aircraft.”

Martin Nüßeler, CTO at Deutsche Aircraft, adds: “Deutsche Aircraft is convinced that the higher propulsive efficiency of propeller powered aircraft will drive the change in propulsion technology and will result in reducing fuel consumption and emissions even further in the future. Combining modern propeller aircraft design with zero-carbon energy sources is central to achieving climate-neutral air transportation. We are looking forward to partner with companies that do not only share our passion for the environment, but also have the technical expertise to ensure that climate-optimized aviation stays safe and reliable. We are convinced the partnership with H2FLY will move us forward on the path to applying hydrogen fuel cells in larger aircraft.”

Related Content

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreWelding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreRead Next

Carbon fiber in pressure vessels for hydrogen

The emerging H2 economy drives tank development for aircraft, ships and gas transport.

Read MoreUniversal Hydrogen Series A funding to build and test full-scale hardware for hydrogen commercial aircraft

$23.5 million in funding to set Universal Hydrogen on a path to have carbon-free airplanes using composite tanks in commercial service by 2025.

Read MoreAirbus ASCEND program to explore liquid hydrogen and superconductivity for zero-emission aircraft

Cryogenic hydrogen as cold source for lightweight, low-electrical loss powertrain, with composite materials as possible insulation.

Read More