CAMX 2022 exhibit preview: Addcomposites, IND Group

The co-exhibition shows customers a more complete visual of the value chains that can be implemented in the composites industry via Addcomposites’ AFP system solutions and IND Group’s cobot platforms.

Addcomposites (Espoo, Finland) and IND Group (Sherbrooke, Quebec, Canada) have teamed up again this year to to showcase upcoming and existing products. As operating partners providing the North American market with turnkey, off-the-shelf automated fiber placement (AFP) and postprocessing robotic solutions, both companies are co-exhibiting to show customers a more complete visual of the value chain that can be implemented.

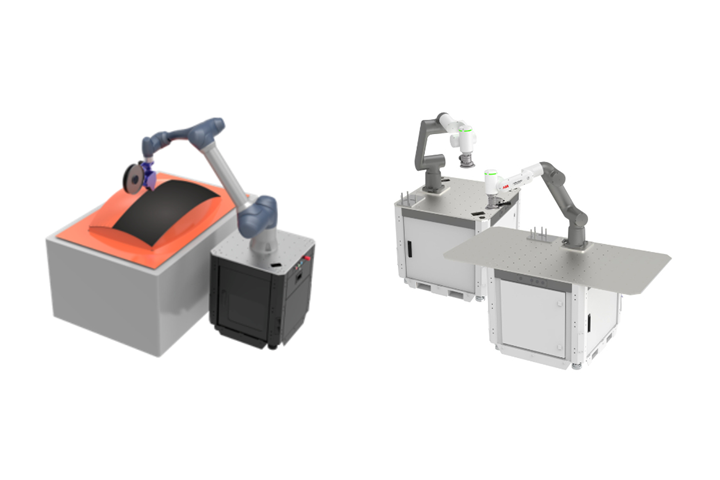

Specifically at the show, Addcomposites supplies the fiber placement head to IND Group, which is integrated into the Group’s cobot solution platform known as Cobii. The Cobii family of products are temporarily available for training purposes, short-term repair jobs or for university teachings. The Cobii products include AFP, trimming, sanding and buffing and other capabilities.

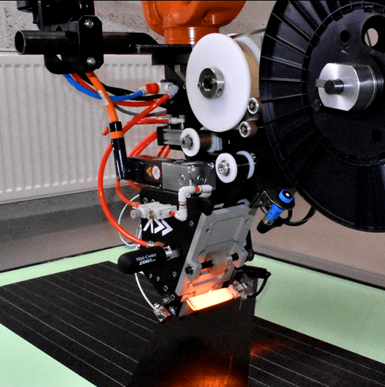

The AFP-XS system, highlighted by Addcomposites, is the company’s standard toolhead. Designed for various industrial robots, it can support the attachment of the humm3 or laser for a quick transition to a thermoplastic fiber placement system, according to the company. This provides visitors the opportunity to physically see the AFP toolhead and how it could perform the layup process.

AFP-XS on various robots.

The AFP-XS has a dry weight of 16 kilograms, enabling a wide range of robotic systems, new and old, to be used as the automation platform for state-of-the-art fiber placement, including cobots. A double tow system was recently developed and installed at University of Texas Arlington, which has reportedly increased carrying capacity by more than 6x and enables the user to place dissimilar fibers without the need to stop the process to swap out materials.

Along with the physical toolhead, Addcomposites also showcases AddPath, the accompanying planning software used to program and plan layups. AddPath gives users the freedom to experiment with different fiber widths, number of tows, heating strategies and more, the company says.

IND Group focuses on lean robotics to supply portable and flexible units that can be deployed and integrated in record time. The Cobii’s short-term rental program, for example, aims to reduce risk to the end user by realizing the proof of concept of a larger industrial system directly at the customer’s facilities in an actual manufacturing environment. Noting that tools like pressure sensors and vision systems working alongside the robot allow the integration of trimming and sanding solutions to complete the value chain in composites manufacturing, a collaborative sanding unit is displayed at CAMX, giving the opportunity for attendees to experience easy programming functions while in teaching mode.

Related Content

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

-

Rocket Lab begins installation of large AFP machine for rocket production

The 99-ton AFP machine, custom-designed and built by Electroimpact, is claimed to be the largest of its kind, expecting to save around 150,000 manufacturing hours in the Neutron rocket’s production process.

-

Plant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.